0 maintenance – Aerovent IM-301 User Manual

Page 3

Aerovent IM-301

3

RPM

AXIAD STANDARD

NEMA

SHUT-

MILS

DOWN

ALARM

3600

0.6 Mils Peak/Peak

1.0

2.20

1.42

1800

0.8 Mils Peak/Peak

1.5

4.40

2.84

1200

1.2 Mils Peak/Peak

2.0

6.70

4.26

900

1.6 Mils Peak/Peak

2.5

8.90

5.60

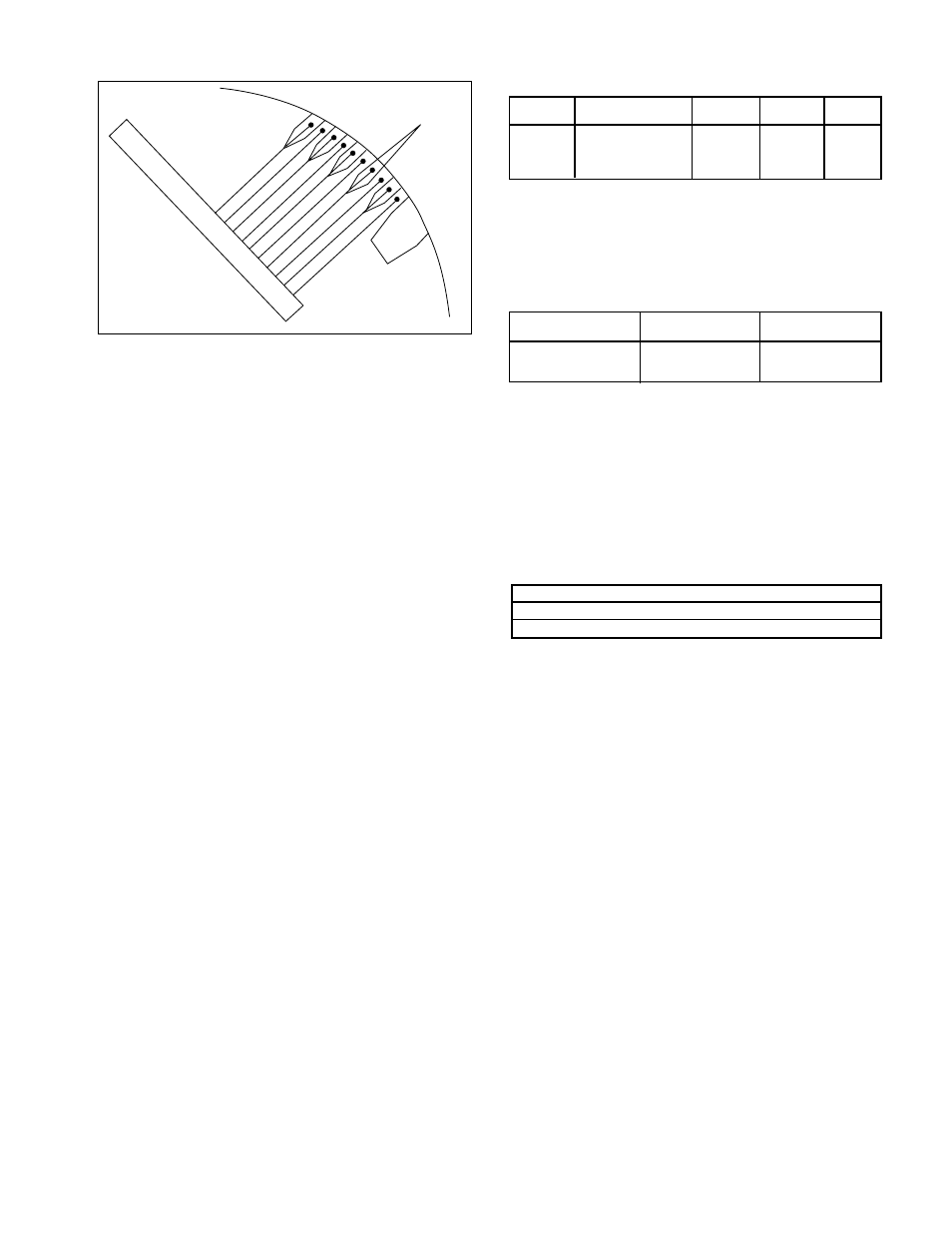

Figure 2. Blade Positions For AXIAD II

INDEX ON

HUB

BL

AD

E

PO

SIT

IO

NS

9

8

7

6

5

4

3

2

1

0

3.1.1 Blade Pitch Adjustment

On Arrangement 4 Type 3 fans, the blade angle can be

adjusted by removing the inlet screen. On ducted fans, the

case is provided with an 8-inch square door in the fan tube. To

set the blade pitch, proceed as follows:

NOTE: A

5

∕

16

" key with a square drive adaptor fitted to

a torque wrench is required. In most cases, a universal joint

will also be needed.

1. After access has been obtained to the rotor, loosen the two

blade bolts until the blade is free to rotate.

2. Rotate the blade to line up the register mark on the fairing

with the desired blade angle mark on the blade.

CAUTION: Do not exceed blade position 9.

3. Tighten the two bolts evenly until a torque level of 65 ft-lb

is reached.

CAUTION: It is important that the blade bolts are torqued

to the specified value. Do not hand-tighten the bolts.

4. Repeat steps 1 through 3 for all blades. Make sure all blades

are set at the same mark.

5. After all blades are set at a new angle, run the fan for a few

minutes and then re-torque all blade bolts.

CAUTION: The motor current should be checked not to

exceed the nameplate rating when blade pitch has been

increased.

4.0 MAINTENANCE

4.1 GENERAL

AXIAD fans are a quality product designed and manu-

factured for minimum maintenance and long operating life.

They should provide years of trouble-free service if the fol-

lowing maintenance procedures are followed.

AXIAD fans are balanced at the factory to the follow-

ing standards. NEMA has set standards for motor balance

which are also shown. Bearing life and lubrication require-

ments are based on the NEMA standard. The more stringent

AXIAD standards allow for normal build-up of dirt on rotors;

use, evaporation and/or shifting of lubricants; and normal

wear. If a fan appears to be out of balance, it is wise to clean

and grease before attempting to balance as this may resolve

the situation in the simplest manner.

4.2 MOTOR LUBRICATION

Motor bearings do not require initial lubrication unless

the fan has been in storage over six months. If this is the case,

the motor should be lubricated initially.

Lubricate motor bearings with grease gun at the follow-

ing intervals and numbers of strokes:

NOTE: Normal amount of grease delivered by a hand car-

tridge type grease gun.

Use only the following lubricants or their equal:

Chevron SR-2

A.F. No.2

Precision No. 2

Gadus S2 V100 2

Starfak H, M and No. 2

Mobilux No.2

Polyrex EP2

Mobil Grease #77

The grease fittings must be clean to prevent contamination.

The fittings are located as follows:

CAUTION: Do not over lubricate bearings or use a grease

other than specified.

4.3 VIBRATION

If excessive vibration develops, the following points should be

checked as possible sources of trouble:

a. With the rotor stopped, determine whether the vibration is

produced by an external source.

b. All anchor bolts on fan must be secure.

c. The rotor must be tight on the motor shaft.

d. Disconnect the motor from the rotor and run it alone to

determine if it produces vibration.

e. Thoroughly clean the rotor and interior of housing and

check the rotor for out-of-balance due to erosion or dam-

age.

4.4 MOTOR BOLT TORQUE

Motor bolts should be torqued to the following speci-

fications. Remember that it is not possible to check a torqued

bolt unless it is loosened first, as torque must be applied

evenly until the desired torque is reached. To tighten further

after a given torque value has been reached requires much

more torque to get the nut started than will be required to

keep tightening it, so the desired final torque must be reached

in one movement. All bolts are grade 5.

TYPE FAN

LOCATION

Arrangement 4, Type 2

Fan case adjacent to conduit box

Arrangement 4, Type 3

End of motor base

HORSEPOWER

PERIOD

STROKES

(SEE NOTE)

5 to 7

1

⁄

2

12 Month

1

10 to 40

6 to 12 Month

3

50 to 150

6 Month

3