Safety, Safe operation 1-1, Electrocution hazards 1-1 – Snorkel SR3370 User Manual

Page 11: Minimum safe approach distance 1-1, Pre-start inspection 1-1, Work place inspection and practices 1-1, Electrocution hazard, 1-1, Pre-start inspection, 1-1, Safe operation, 1-1, Work place inspection and practices, 1-1

1. Safety

n Safe Operation

Knowl edge of the in for ma tion in this man ual, and

proper train ing, pro vide a ba sis for safely op er at ing

the SR3370 / SR2770. Know the lo ca tion of all the

con trols and how they op er ate to act quickly and re -

spon si bly in an emergency.

Safety de vices re duce the like li hood of an ac ci -

dent. Never dis able, mod ify, or ig nore any safety

de vice. Safety alerts in this man ual in di cate sit u a -

tions where ac ci dents may occur.

If any mal

func

tion, haz

ard or po

ten

tially un

safe

con di tion re lat ing to ca pac ity, in tended use, or safe

op er a tion is sus pected, stop the op er a tion of the

SR and seek assistance.

The op er a tor bears ul ti mate re spon si bil ity for fol -

low ing all man u fac tur ers in struc tions and warn -

ings, reg u la tions and safety rules of their em ployer

and/or any coun try or regional law.

n Electrocution Hazards

The SR is an all metal ae rial work plat form and is

not elec tri cally in su lated. Do not op er ate it near

elec tri cal con duc tors. Re gard all con duc tors as be -

ing en

er

gized. Do not op

er

ate out

side dur

ing a

thunderstorm.

q

Minimum safe approach distance

Min

i

mum safe ap

proach dis

tances to energised

power lines and their as so ci ated parts must be ob -

served wile op er at ing the SR.

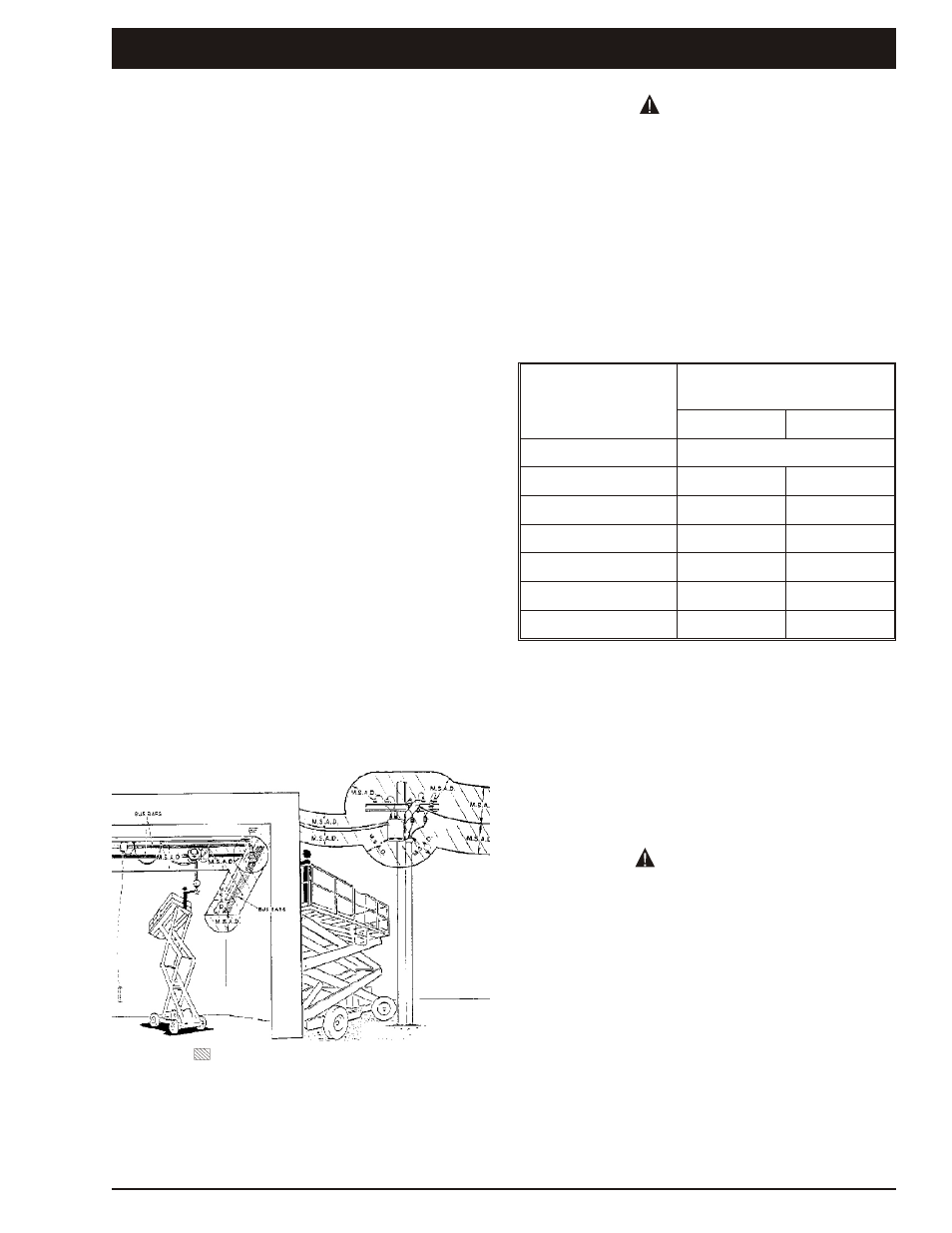

Figure 1. - Minimum Safe Approach Distance

The SR is not electrically insulated. Death or

serious injury can result from contact with, or

inadequate clearance from, an energised

conductor. Do not go closer than the minimum

safe approach distance as defined by ANSI.

ANSI pub li ca tions de fine min i mum dis tances that

must be ob served when work ing near bus bars and

energised power lines. Fig ure 1 and Ta ble 1 are re -

printed cour tesy of the Scaf fold in dus try As so ci a -

tion, ANSI/SIA A92.5.

Table 1. - Minimum Safe Approach Distance

n Pre-start Inspection

At the start of each work shift, the SR3370 /

SR2770 shall be given a vi

sual in

spec

tion and

func tion test. See the Daily In spec tion and Main te -

nance chap ter , in this man ual for a list of items to

in spect and test.

DO NOT operate the SR3370 / SR2770 unless

you are trained and authorized, understand the

operation characteristics of the SR3370 /

SR2770, and have inspected and tested all

functions to be sure they are in proper working

order.

n Work Place Inspection and Practices

Do not use the SR3370 / SR2770 as a ground for

weld ing. Ground to the work piece.

Be fore the SR3370 / SR2770 is used, and dur ing

use, check the area in which the SR3370 / SR2770

is to be used for pos si ble haz ards such as, but not

lim ited to:

SR3370 & SR2770 – 12696A

Rev B

page 1 - 1

Denotes prohibited zone

Caution: - Diagrams shown are only for purposes of illustrating

M.S.A.D. Work positions, not all work positions.

Voltage Range

(Phase to Phase

Minimum Safe Approach

Distance

Feet

Metres

0 to 300V

Avoid Contact

Over 300V to 50kV

10

3.05

Over 50kV to 200kV

15

4.60

Over 200kV to 350kV

20

6.10

Over 350kV to 500kV

25

7.62

Over 500kV to 750kV

35

10.7

Over 750kV to 1000kV

45

13.72

DANGER

WARNING