Chapter 7. pre-operational inspection, Warning, Danger – Snorkel SP22 User Manual

Page 35

Chapter 7. Pre-operational Inspection

Potential service and safety problems may be

detected by inspecting the aerial platform every

day (or 8 hour shift).

This chapter includes a Pre-operational Inspection

table (refer to Figure 6.1) and information on

properly inspecting each item listed in the table.

The purpose of the Pre-operational Inspection is to

keep the SP in proper working condition and to

detect signs of malfunction at the earliest possible

time.

Perform the inspection at the beginning of each

shift before using the aerial platform on the job.

The inspection site must have a smooth and level

surface. Use the Pre-operational Inspection table

to ensure no areas are overlooked.

Set the Key Switch to OFF before you begin this

inspection.

The potential for an accident increases when

operating an aerial platform that is damaged

or malfunctioning.

Death or se ri ous in jury can re sult from such

ac ci dents.

Do not op

er

ate the ae

rial plat

form if it is

dam aged or mal func tion ing.

R e

p a i r a l l e q u i p

m e n t d a m

a g e o r

mal

func

tions be

fore plac

ing the SP into

ser vice.

SP20/SP22 – 11890A

page 7 - 1

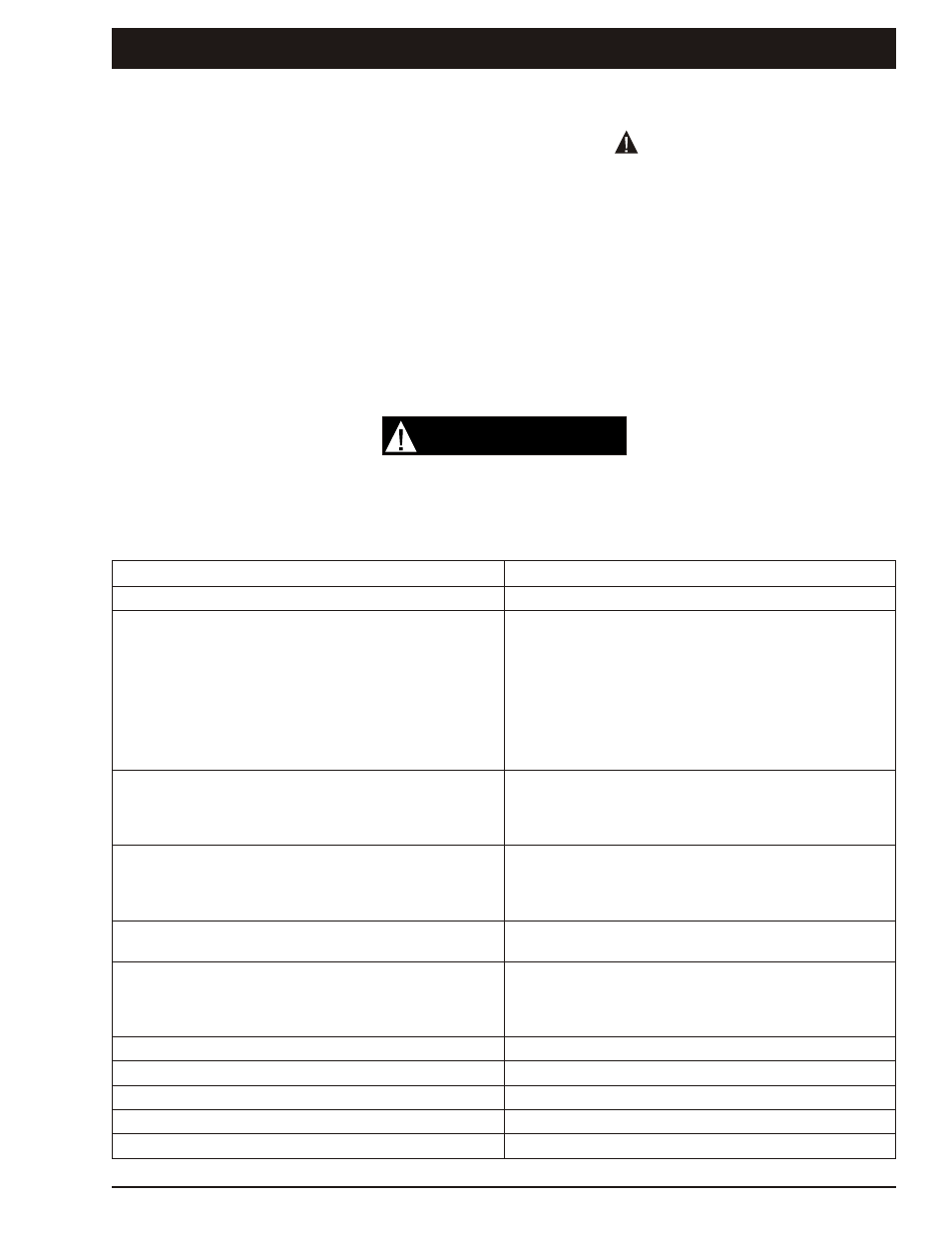

Item

Inspect for

Operator’s manual

In manual holder

Engine

Oil level

Coolant

Fuel tank

Fuel line

Air filter

Charging system

Between full and add marks

Liquid cooled engines-proper fluid level

Air cooled engines-air intake and fan free of

obstructions. Belt in good condition

Tank full, cap in place and tight

No leaks

Yellow disk in the green zone

Proper operation

Electrical system

Battery fluid level

Battery terminals

Cables and wiring harness

Proper level

Clean, connectors tight

No wear or physical damage

Hydraulic system

Fluid level

Fluid filter

Hoses, tubes, and fittings

Between full and add marks

Verify operation in the green or yellow zone

No leaks

Tires and wheels

Foam filled

Good condition

Lower control station

Operating controls

Emergency stop

Emergency power

Proper operation

Shuts off lower controls

Proper operation

Emergency lowering

Proper operation

Level sensor

Sounds tilt alarm

Flashing light

Proper operation

Hostile environment kit

In place and proper operation

Sound suppression kit

In place and proper operation

DANGER

WARNING

If pre-operational and periodic inspections are neglected, it will not be possible to detect problems in their early

stages or prevent consequent accidents.

Make it a habit to perform the recommended pre-operational and periodic inspections. If any abnormality is

found, take corrective action immediately.