Danger – Snorkel S3219E-sn000017+ User Manual

Page 30

Chapter 8 – Prestart Inspection

26

S3219E/S4732E – 1500834

Weldments

To inspect the weldments:

1. Visually inspect all weldments for abnormal wear,

abrasion, or deformation that could cause interfer-

ence between moving parts.

2. Inspect the welds on the structural components. The

area to be inspected should be clean and free of dirt

and grease.

3. Look for visible cracks in the welds and at the weld

to parent material joints. A bright light may be used

to provide adequate visibility of the inspection area.

4. Pay close attention to welds in areas where changes

in cross section take place and near the attachment

points of highly loaded components.

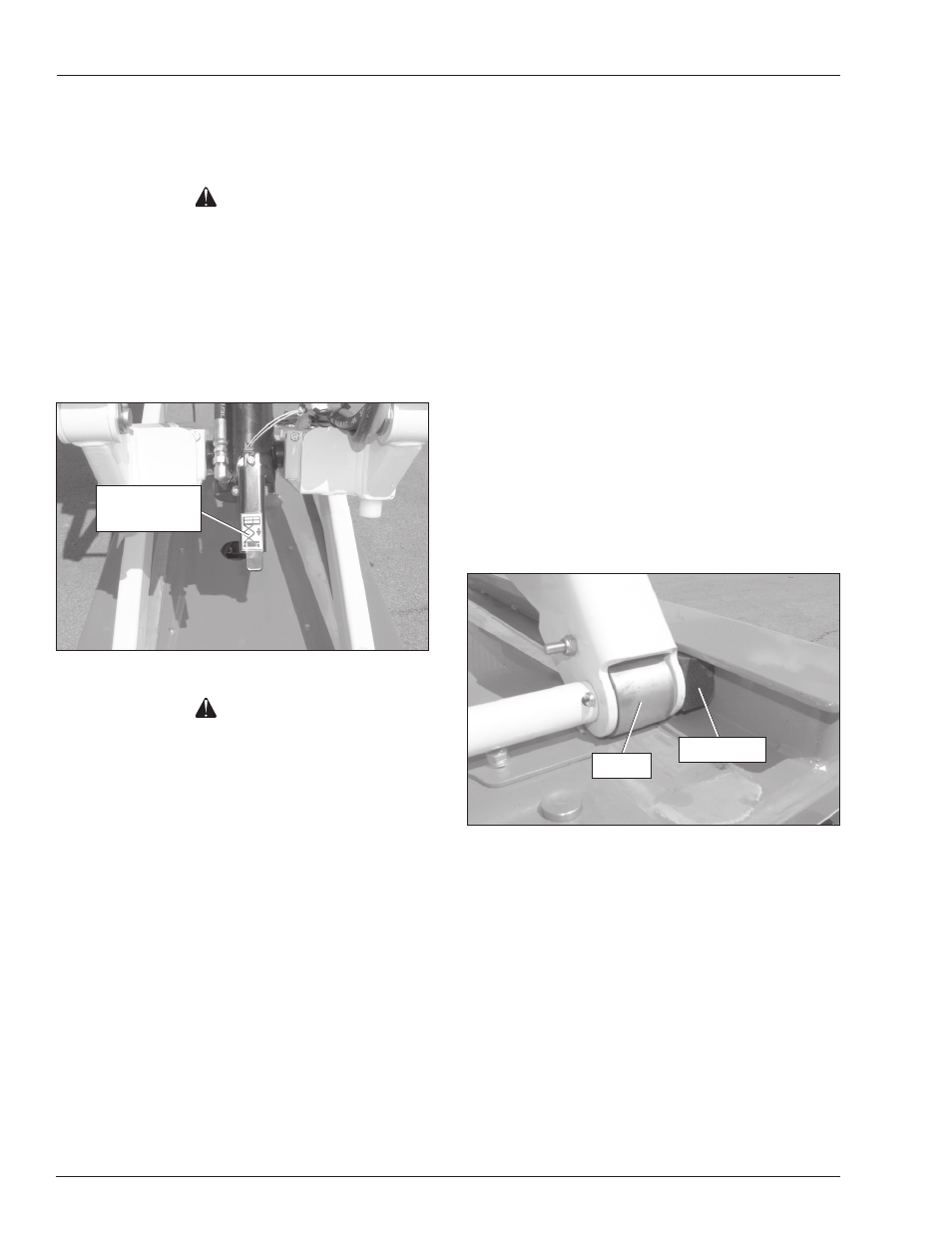

Rollers and Slide Blocks

To inspect the rollers and slide blocks:

1. Visually inspect the scissors arm rollers and slide

blocks (refer to Figure 8.14). They must be free to

move without obstruction. There is one roller and

slide block on each side of the chassis.

Figure 8.14 – Front of Chassis

2. Raise the platform from the lower controls and visu-

ally inspect the slide blocks underneath the front of

the platform (refer to Figure 8.15). There is one slide

block on each side of the platform. The slide blocks

must be in good condition and free to move without

obstruction.

Emergency Lowering System

Use the following procedure to test the emergency lower-

ing system:

Danger

Pinch points may exist between moving components.

Death or serious injury will result from becoming

trapped between components. Stand clear of moving

components while test operating the machine.

1. Use the lower controls, fully raise the platform. Push

the emergency stop button inward.

2. Locate the emergency lowering lever at the front of

the aerial platform (refer to Figure 8.13).

Figure 8.13 – Front of Machine

Danger

Pinch points may exist between moving components.

Death or serious injury will result from becoming

trapped between components. Make sure all person-

nel stand clear while lowering the platform with the

emergency lowering lever.

3. Make sure there is nothing in the way to obstruct the

platform when it lowers.

4. While standing clear of the scissors structure, push

downward on the lever to lower the platform. The

platform will begin to lower as the lever is pushed

down.

5. Release the lever to stop the platform from lowering.

Structures

Visually inspect all weldments and related components.

It is important to inspect the fasteners that connect the

components.

Slide Block

Roller

Emergency

Lowering Lever