Snorkel S2033CE User Manual

Page 50

Chapter 12 – Troubleshooting

46

S2033 – 330003EE

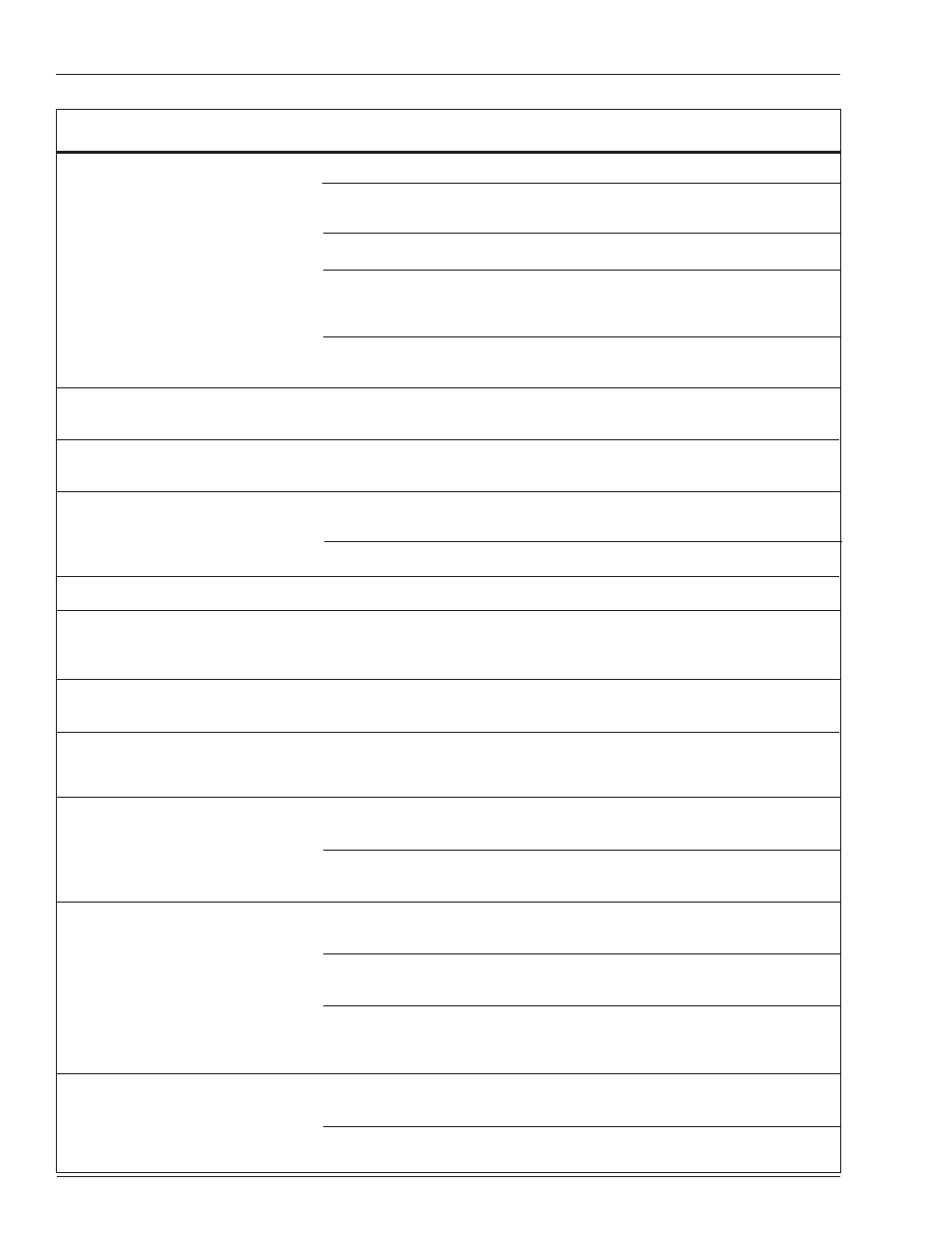

Symptom

Drive functions don’t work.

Only slow drive speed works.

Machine will not steer.

Wheels won’t turn when

winching or pushing.

Circuit breaker will not reset.

Brakes don’t work.

Swing-out tray will not open

or close.

Tilt alarm does not work.

Ammeter does not indicate a

reading when charging the

batteries.

Hydraulic fluid temperature of

71°C (160°F) or more.

Severe hydraulic leak.

Possible Cause

Drive/lift selector is in the lift position.

Machine is not on a level surface or

too steep a grade.

Free-wheeling valve is open.

Load capacity exceeded.

Low hydraulic system pressure.

Platform elevated above 1.8 m (6

′).

Joystick interlock switch not engaged.

Brake pins are engaged.

Free-wheeling valve closed.

Electrical system malfunction.

Brakes pins not engaged.

Pothole protector skid is in the way.

Platform is not raised more

than 1.8 m (6

′).

No source of power.

Circuit breaker on lower control panel

has tripped.

Charger power fuse is blown.

Prolonged driving or platform opera-

tion.

High pressure fluid return to reservoir

caused by kinked or twisted hose.

Hydraulic system component failure.

Failure of hose, tube, fitting, seal, etc.

Corrective Action

Place the switch in the drive position.

Lower the platform and drive to a level

surface.

Fully close the free-wheeling valve.

Remove load from platform. Refer to

platform capacity placard for maxi-

mum capacity.

Stow the machine and do not oper-

ate until repairs are made.

Lower platform to drive machine at mid

and high speed.

Engage the interlock switch before

operating the steer switch.

Rotate brake release cams to disen-

gage brakes.

Fully open free-wheeling valve.

Manually stow the machine.

Manually release brake cams with a

wrench or drive the machine to reset

the brakes.

Pull handle toward you to lower the

skid.

Normal operation. The tilt alarm is not

active until the platform is raised more

than 1.8 m (6

′).

Make sure power source is plugged

in and turned on.

Press the circuit breaker reset but-

ton.

Stow the machine and do not oper-

ate until repairs are made.

Stop operation until fluid cools.

Remove the kink or twist from the

hose. Let fluid cool before resuming

operation.

Stow the machine and do not oper-

ate until repairs are made.

Stow the machine and do not oper-

ate until repairs are made.