2 visual and function check – Lukas P 630 SG User Manual

Page 25

25

Visual Inspection

• Tightness of all hydraulic connections,

• General tightness, no leakage (sweated oils do not have any in

À uence on the function),

• is there any detectable damage to the engine, connecting blocks, on the frame or the side

sections,

• Is there any sign of damage to the hydraulics or fuel tank,

• Side plates present and tightened,

• Presence and legibility of the identi

¿ cation plate, all actuation signs, instruction signs,

markings and warnings,

• The presence and perfect condition of all covers (e.g. exhaust de

À ector),

• All

À uid levels are within the speci¿ ed tolerances,

• Are the rotary switches and switching levers in proper working order and undamaged,

• Couplings must be easy to couple,

• Dust protection caps must be available,

• All required accessory parts (e.g. sparking plug, sparking plug spanner and fuel can) are

present.

• Check for leaks.

Functional test

• Unconventional or noticeable noises heard during operation

• Cable-pull starter fully functional,

• Engine switch fully functional,

• Test for maximum load.

10.2 Visual and function check

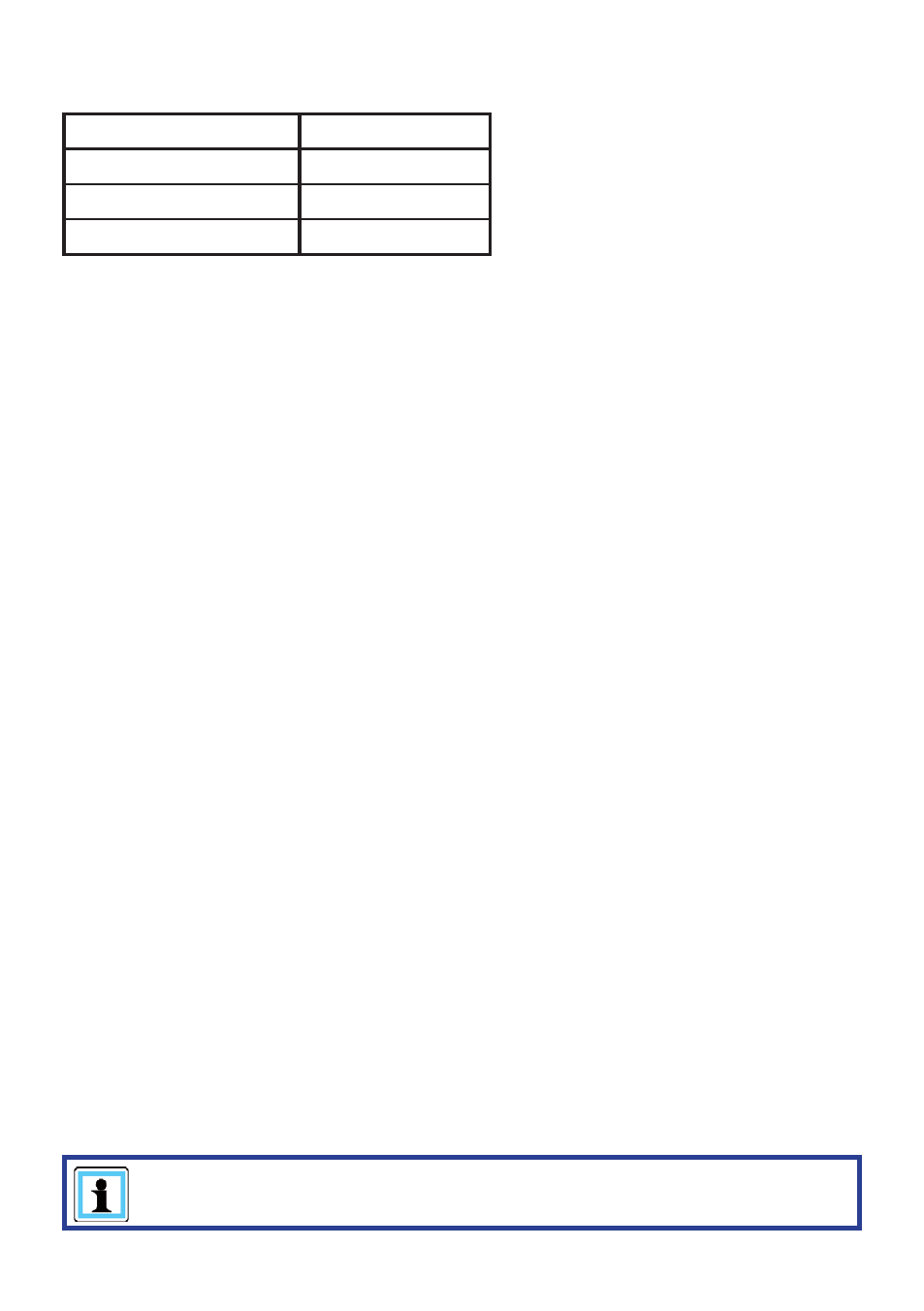

Operating time per day

Functional test

up to 1 hour

1 x annually

up to 8 hours

1 x per quarter

up to 24 hours

1 x per month

In addition to these test intervals you need to carry out a function test if:

-

the unit makes suspicious noises,

-

there is a justifi ed suspicion of internal damage to the unit.

If the noises and suspicions referred to above arise several times in a month, or if maximum

pressure cannot be achieved during the function test, you need to contact LUKAS customer

service immediately. The contact details are given in the Chapter "Fault analysis".

10.1.2 Function

check

NOTE:

use the LUKAS test kit, including testing instructions, for the function test.