Linear actuator, Ptec ii – Class1 Pump Throttle Electric Cotnrol Series 2 User Manual

Page 7

7

PTEC II

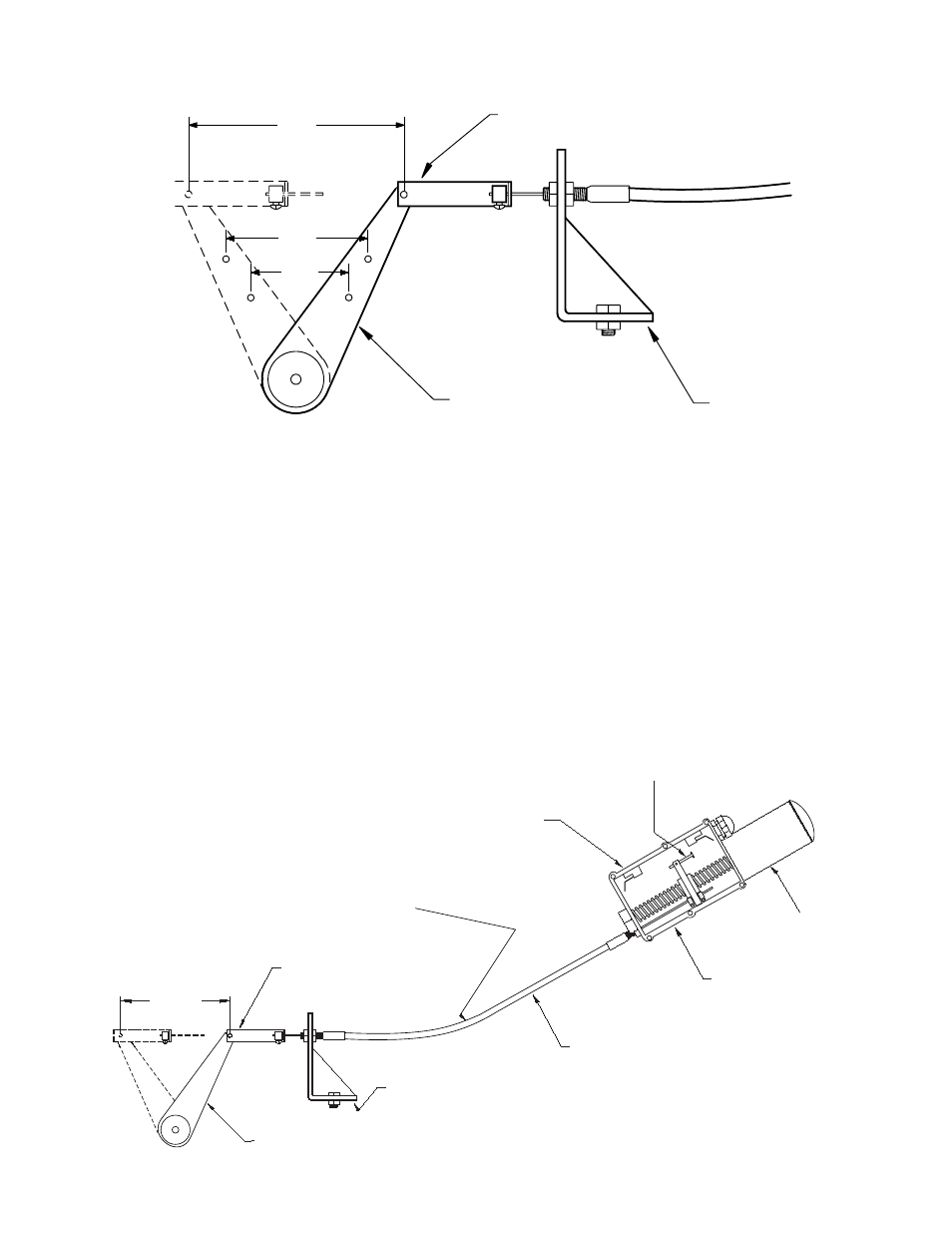

Fuel Control Arm

Cable Support Bracket

Linkage Assembly

3" Stroke

1"Stroke

2" Stroke

Actuator Resolution

The further out on the control arm that the actuator cable is installed,

the better the actuator resolution.

In most cases the fuel control arm needs to be extended to make best

use of the 3" actuator stroke.

Ideally, a small amount of actuator movement should result in very minor

changes in RPM.

If the actuator installation has poor resolution, the result will be uncontrollable

engine oscillations as the governor attempts to find the setpoint and overshoots

that setpoint each time. There are adjustments that can be made to the ECU that

will adjust for minor inadequacies, but CAN NOT compensate for a bad

installation

THROTTLE ACTUATOR CABLE

MAINTAIN A SMOOTH RADIUS TRANSITION

IN THE ACTUATOIR CABLE. CABLE MUST

NOT EXCEED A 90 DEGREE CORRECTION

CHANGE.

LINKAGE ASSEMBLY

FUEL CONTROL ARM

CABLE SUPPORT BRACKET

3" STROKE

THROTTLE ACTUATOR BODY SHOULD BE LOCATED

ABOVE THE LINKAGE ASSEMBLY POINT TO PREVENT

WATER DAMAGE IN THE EVENT THE CABLE SHEATH

IS DAMAGED OR SCORED.

THROTTLE ACTUATOR

Adjust this pin to limit retraction of the actuator rod.

MOTOR

Linear Actuator

Linear Throttle Actuator Setup

NOTE: the engine should not be running during setup.

There is a limit switch at the end of the actuator travel, this should be set so that the actuator can not travel further

than the engine throttle linkage full throttle position.

It is important that the ram be adjusted and that the tangs on the limit switches are not bent.

The actuator cable should be attached to the throttle linkage and there should be no interference with normal

throttle movement. The cable should not bind or bend at either extreme of travel.