Fyr pak operation and maintenance manual – Hale Fyr Pak(2006 to Present) User Manual

Page 20

Fyr Pak

Operation and Maintenance Manual

20

Reassembly Note:

Before Reassembly visually inspect parts. See that parts are clean and all sealing surfaces are free of corrosion

and nicks. Remove any metal chips from casting cavities and tapped holes. Also inspect for any damaged or

excessively worn parts which should be replaced.

a. Coat the engine crankshaft with a thin layer of gasket sealer, such as, Loctite Gasket Eliminator 504

b. Lubricate the groove in the pump shaft sleeve using a multipurpose grease and install “O”-ring in

groove. Slide this assembly on engine crankshaft.

c. Position pump head on engine and align holes. If original screws are in good condition, reuse, but

apply a thread locking adhesive, such as Loctite Threadlocker 242 or equal to threads. If original

screws were damaged, or corroded, replace with four new screws. When installing screws use a new

brass sealing washer under the head of each screw.

Note: Hale has available small tubes of Loctite Threadlocker 242 adhesive (0.5 cc). Hale

P/N: 029-0010-01-0.

d. Coat rubber cup of mechanical seal seat with dish soap or Pac Ease and press into pump head

with polished surface toward you.

e. Coat rubber on inside of mechanical seat carbon sealing washer with dish soap or Pac Ease.

Using a turning motion, push onto shaft sleeve until carbon lip comes into contact with the seat

installed in step d.

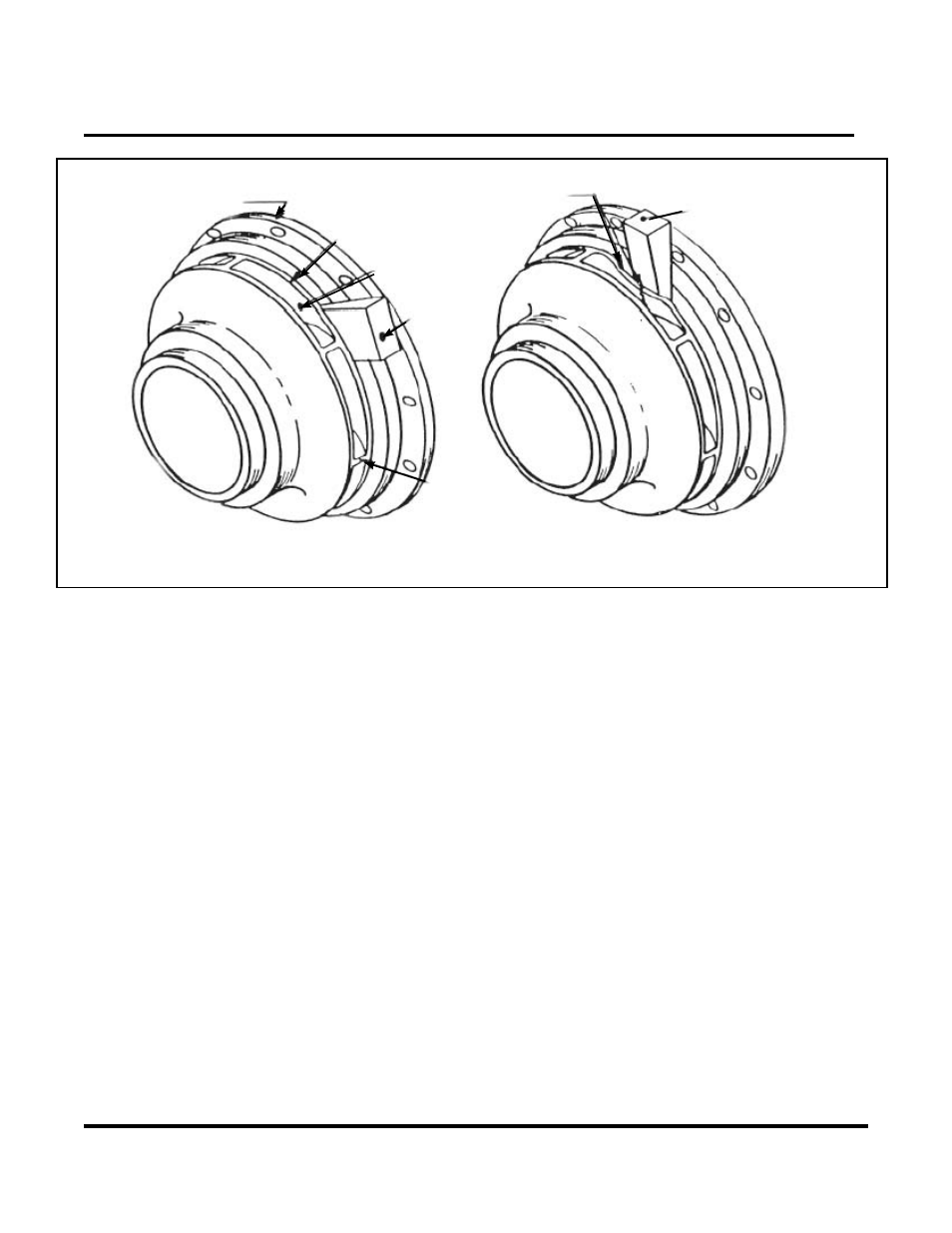

CORRECT

INCORRECT

Pump Head

Impeller Disc

Impeller Cavity

Wedge

Impeller Vane

Bent or Cracked

Impeller disc

Wedge