Accessory usage guideline – Bryant ELECTRIC AIR CONDITIONER 561C User Manual

Page 7

—7—

* Permissible limits of the voltage range at which unit will operate satisfactorily. Operation outside these limits may result in unit failure.

† If wire is applied at ambient greater than 30°C (86°F), consult Table 310-16 of the NEC (ANSI/NFPA 70).

The ampacity of nonmetallic-sheathed cable (NM), trade name ROMEX, shall be that of 60°C (140°F) conductors, per the NEC (ANSI/NFPA 70) Article 336-26.

If other than uncoated (non-plated), 60 or 75°C (140 or 167°F) insulation, copper wire (solid wire for 10 AWG and smaller, stranded wire for larger than

10 AWG) is used, consult applicable tables of the NEC (ANSI/NFPA 70).

‡ Length shown is as measured 1 way along wire path between unit and service panel for voltage drop not to exceed 2%.

** Time-delay fuse or circuit breaker.

†† Start assist capacitor and relay required when using liquid solenoid valve or hard shutoff TXV (except 036 and 042, Series A; 048 and 060, Series A/B

single phase; and all 3-phase units). Do not use hard shutoff TXV with liquid solenoid valve.

‡‡ Use with low-ambient controller.

*** Fan motor with ball bearings required.

N/A—Not Applicable

NOTES:

1. All motors/compressors contain internal overload protection.

2. Copper wire must be used from service disconnect to unit.

3. Control circuit is 24v on all units and requires external power source.

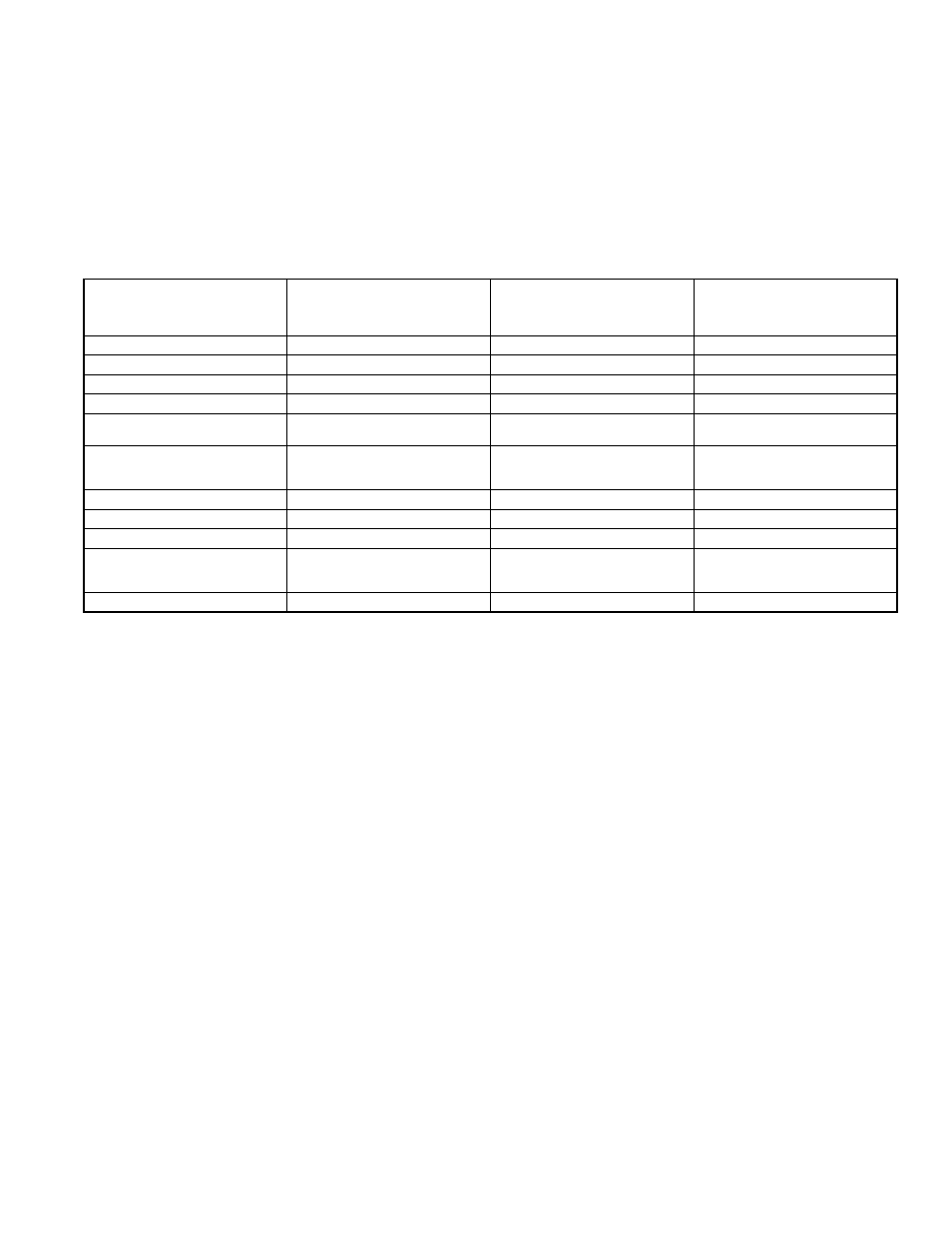

ACCESSORY USAGE GUIDELINE

* For tubing line sets between 50 and 175 ft, refer to Residential’s Split Systems Long-Line Application Guidelines.

† Only when low-pressure switch is used.

ACCESSORY DESCRIPTION AND USAGE (Listed Alphabetically)

1. Ball Bearing Fan Motor

A fan motor with ball bearings which permits speed reduction while maintaining bearing lubrication.

SUGGESTED USE: Required on all units where Low-Ambient Controller (full modulation feature) or MotorMaster® Control has been added.

2. Coastal Filter

A mesh screen inserted under the top cover and inside the base pan to protect the condenser coil from salt damage without restricting airflow.

SUGGESTED USE: In geographic areas where salt damage could occur.

3. Compressor Start Assist—Capacitor/Relay Type

Start capacitor and start relay which gives ‘‘hard’’ boost to compressor motor at each start-up.

SUGGESTED USE: Installations where interconnecting tube length exceeds 50 ft.

Installations where outdoor design temperature exceeds 105°F (40.6°C).

Replacement installations with hard shutoff expansion valve on indoor coil.

Installations where Liquid-Line Solenoid Valve has been added.

4. Compressor Start Assist—PTC Type

Solid-state electrical device which gives a ‘‘soft’’ boost to compressor motor at each start-up.

SUGGESTED USE: Installations with marginal power supply.

Replacement installations with rapid pressure balance (RPB) expansion valve on indoor coil.

5. Crankcase Heater

An electric resistance heater which mounts to the base of the compressor to keep the lubricant warm during off cycles. Improves compressor lubrication

on restart and minimizes chance of refrigerant slugging. May or may not include a thermostat control.

SUGGESTED USE: When interconnecting tube length exceeds 50 ft.

When unit will be operated below 55°F (12.8°C) outdoor air temperature. (Use with Low-Ambient Controller.)

All commercial installations.

6. Cycle Protector

Solid-state timing device which prevents compressor rapid recycling. Control provides an approximate 5-minute delay after power to the compressor has

been interrupted for any reason, including normal room thermostat cycling.

SUGGESTED USE: Installations in areas where power interruptions are frequent.

Where user is likely to ‘‘play’’ with the room thermostat.

All commercial installations.

Installations where interconnecting tube length exceeds 50 ft.

High-rise applications.

7. Evaporator Freeze Thermostat

An SPST temperature actuated switch which stops unit operation when evaporator reaches freeze-up conditions.

SUGGESTED USE: All units where Winter Start Control has been added.

8. Filter Drier

A device for removing contaminants from refrigerant circulating in an air conditioner: 1-direction flow.

SUGGESTED USE: All split-system units.

ACCESSORY

REQUIRED FOR

LOW-AMBIENT

APPLICATIONS

(Below 55°F)

REQUIRED FOR

LONG-LINE

APPLICATIONS*

(Over 50 Ft)

REQUIRED FOR

SEA COAST

APPLICATIONS

(Within 2 Miles)

Crankcase Heater

Yes

Yes

No

Evaporator Freeze Thermostat

Yes

No

No

Winter Start Control

Yes†

No

No

Accumulator

No

No

No

Compressor Start Assist

Capacitor and Relay

Yes

Yes

No

Low Ambient Controller

or

MotorMaster® Control

Yes

No

No

Wind Baffle

See Low-Ambient Instructions

No

No

Coastal Filter

No

No

Yes

Support Feet

Recommended

No

Recommended

Liquid-Line Solenoid Valve

or

Hard Shutoff TXV

No

See Long-Line

Application

Guideline

No

Ball Bearing Fan Motor

Yes

No

No