Prepare the burner for start-up, Instruction manual – model cf1400 oil burner, Continued ❏ z dimension – Beckett CF 1400 User Manual

Page 12: Adjusting plate assembly, Initial head position, Initial air settings

12

Form 6104 BCF14N-R0299

Instruction Manual – Model CF1400 Oil Burner

Prepare the burner for start-up

- continued

❏ Z dimension

• Should be set per these instructions (see page 7). The top

acorn nut (

Figure 11

, item

d

) should never be loosened

once the

Z

dimension is initially set.

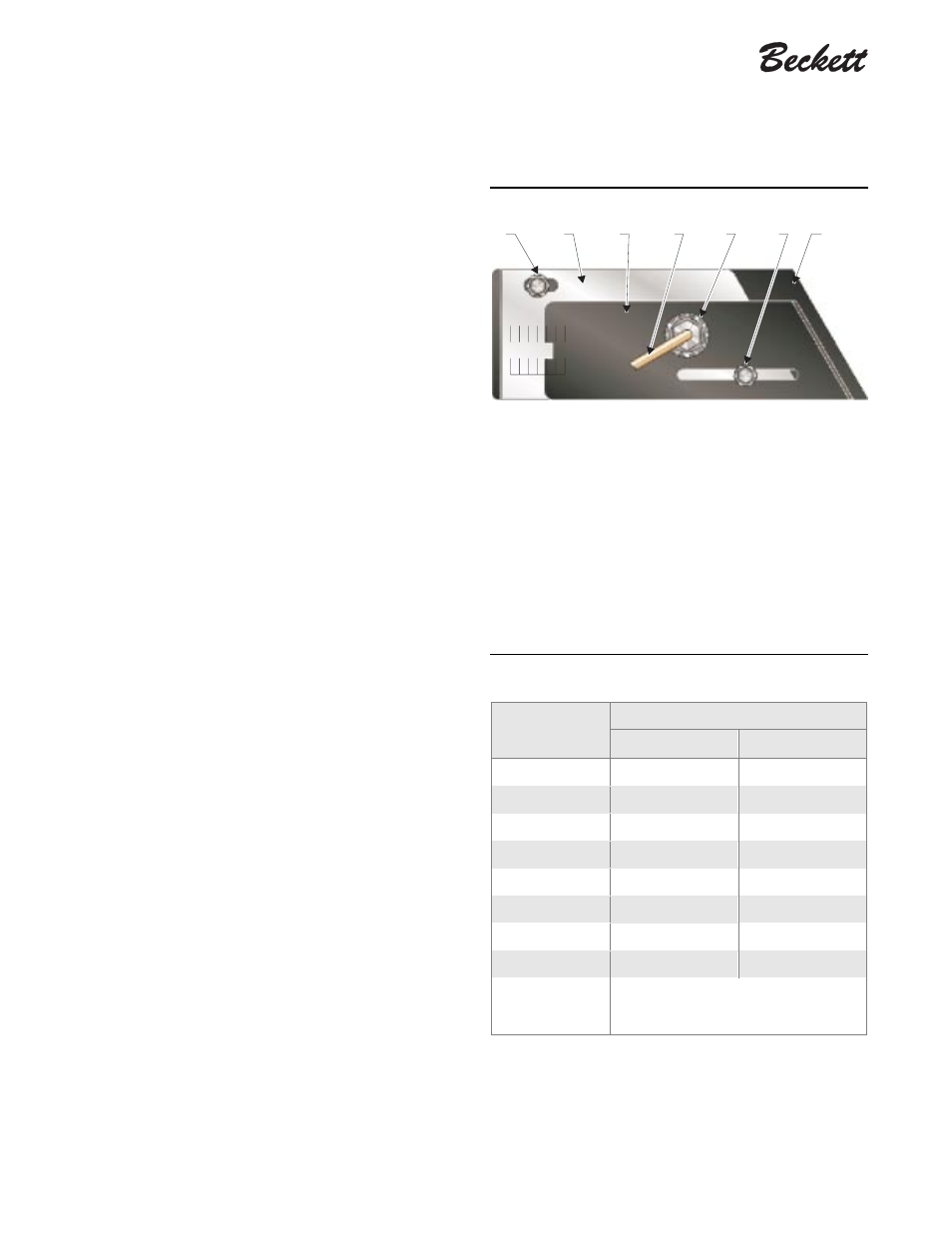

❏ Adjusting plate assembly

(Figure 11)

• Make sure spline nut (item

b

) and bottom acorn nut (item

c

) are loose.

❏ Initial head position

(Figure 11)

• The indicator plate assembly (item

e

) markings correspond

to head position settings.

• Slide the secondary adjusting plate (item

f

) toward the rear

of the burner until the number on the indicator plate corre-

sponds to the initial head setting given in

Table 4

for the

desired firing rate.

•

Figure 11

shows a typical example, with a head setting of

5

.

• When the head position has been set, tighten the bottom

acorn nut (item

c

) and the spline nut (item

b

).

❏ Initial air settings

(Figure 12)

• Loosen the screw holding the air adjusting plate (item

m

).

Set the air to the desired rate. (The numbers on this plate

correspond to the approximate firing rate settings given in

Table 5

.)

• Rotate the air adjusting plate until the lower edge of the

pointer is opposite the number from

Table 5

corresponding

to the desired firing rate.

• This initial setting should be adequate for starting the

burner. Once the burner is in operation, the air setting will

be adjusted for best performance as discussed later in this

manual.

• Follow the procedures given later in this manual for fine-

tuning the air settings.

Figure 11 – Adjusting plate initial setting, typical

1407

9

3

4

5

6

7

8

e

g

c

d

f

b

h

Legend (Figure 11)

b Spline nut for securing nozzle line

c Bottom acorn nut (for head adjustments)

d Top acorn nut (for setting dimension Z only

— do not loosen after setting dimension Z)

e Indicator adjusting plate

f

Secondary adjusting plate

g Primary adjusting plate

h Copper oil line from oil valve to nozzle line

Table 4 – Initial indicator adjustment plate settings

(head position)

Approximate

adjusting plate

settings

Firing rate, gph

Tube “A”

Tube “B”

0

—

—

1

—

—

2

4.00

—

3

6.00

—

4

7.00

7.00

5

8.00

8.00

6

10.00

10.00

7 – 12

—

—

NOTE

These settings are approximate, and can very

depending on actual job conditions and over-

fire pressure.