Outstanding boom technology, Powerful carrier drive – Liebherr LTM 1500-8.1 User Manual

Page 4

4

LTM 1500-8.1

• Weight optimized and low maintenance axles of high-tensile

steel; perfect track keeping and lateral stability due to special

control linkage arrangement

• Steering knuckles mounted on steel bearings, thus bearing

failures are practically ruled out

• The perfected and robust axles are manufactured in large

series and are part of the trouble-free components of a mobile

crane

• The cardan shafts in the axles are maintenance-free and are

safely located within the axle body. 70

° diagonal toothing

enables easy and fast fitting by just a few screws.

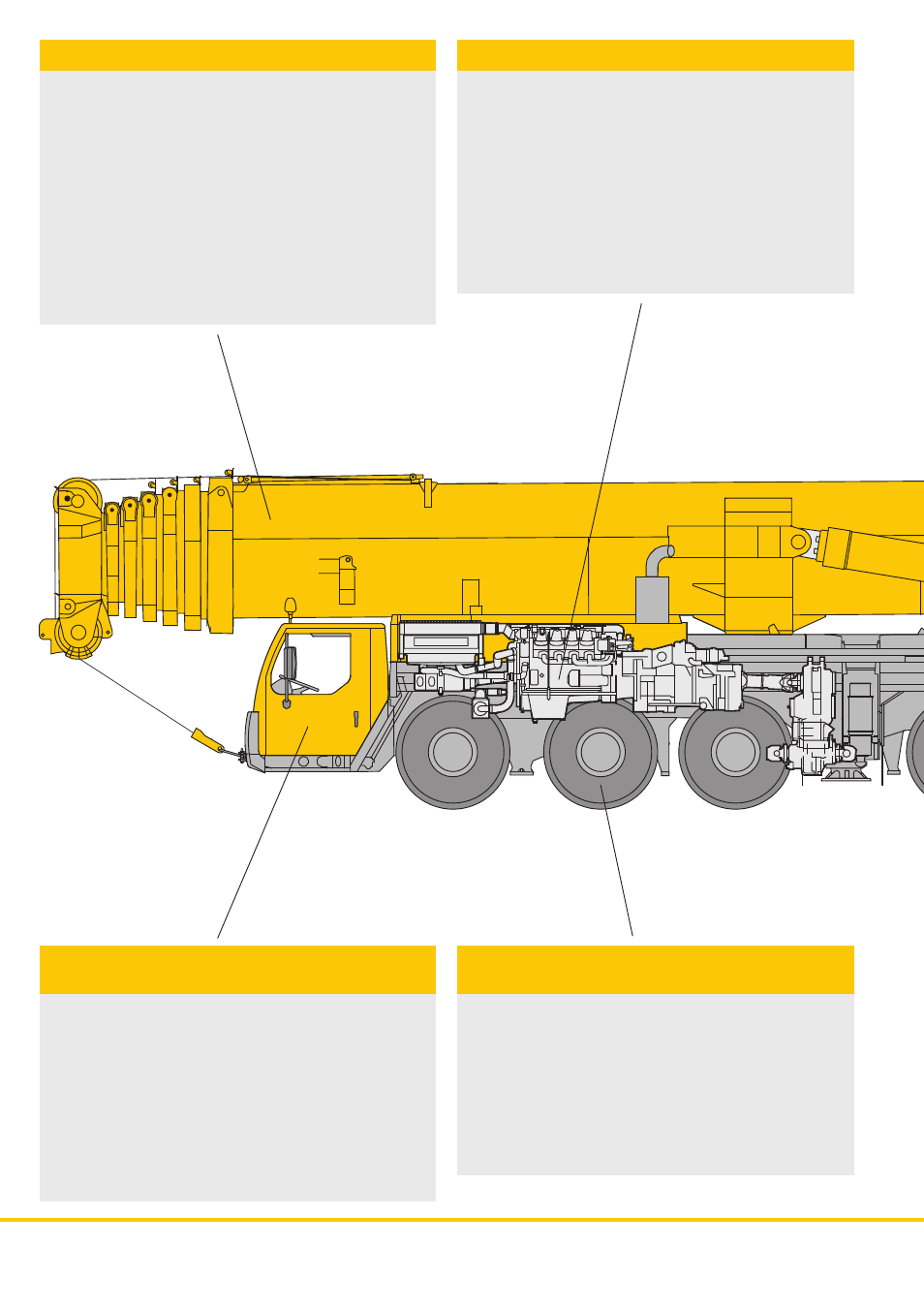

Outstanding carrier technology for

road and off-road application

• Focal points of the new boom technology:

- oviform boom profile

- patented internal interlocking system of

the telescopes

- automatic telescoping system

• Telescopic boom with electronically controlled telescoping

system

• Boom bearings of low maintenance polyamide

slide blocks

• Outstanding lifting capacities, e.g.

161 t at 10 m radius

77 t at 20 m radius

37.4 t at 40 m radius

21.4 t at 60 m radius

13 t at 80 m radius

3.6 t at 108 m radius

Outstanding boom technology

• 8-cylinder Liebherr turbo-charged Diesel engine D9508 A7

of 500 kW/680 hp, exhaust emissions acc. to 97/68/EG stage

3 and EPA/CARB Tier 3, energy-saving, emission-optimized,

robust and reliable, electronic engine management

• Automated gear system ZF-TC-TRONIC with converter

and retarder, 12 forward and 2 reversed speeds, automated

control

• Transfer case

• Robust crane axles, welded design

• Max. driving speed 80 km/h

• In addition to the service and parking brakes, the following

sustained-action brakes: Exhaust brake with Liebherr auxiliary

brake system by valve control, intarder filled to transmission,

Telma-type eddy current brake on 4th axle

Powerful carrier drive

• The data transmission to the individual functional blocks is

realized digitally by just a few data cables instead of the

traditional electrical wiring. Thus, increased functional reliability

and essentially less contacts

• Self-manufactured bus systems, especially adapted to the

requirements of a mobile crane

• The vehicle and crane electrics with all cockpit functions, the

outrigger system and the boom sensor system are

interconnected by 6 Liebherr system busses

• Comprehensive diagnostic facilities, quick

localization of errors

• The new data bus technique provides a distinctive increase

in functionality and efficiency

Data bus technique revolutionizes

crane electric system

4

LTM 1500-8.1