Multivariable counterweight system – Liebherr LTM 1500-8.1 User Manual

Page 18

18

LTM 1500-8.1

15 t

15 t

15 t

15 t

15 t

15 t

15 t

105 t

15 t

15 t

15 t

15 t

15 t

15 t

15 t

15 t

15 t

165 t

135 t

105 t

15 t

15 t

15 t

15 t

15 t

15 t

15 t

105 t

15 t

15 t

165 t

135 t

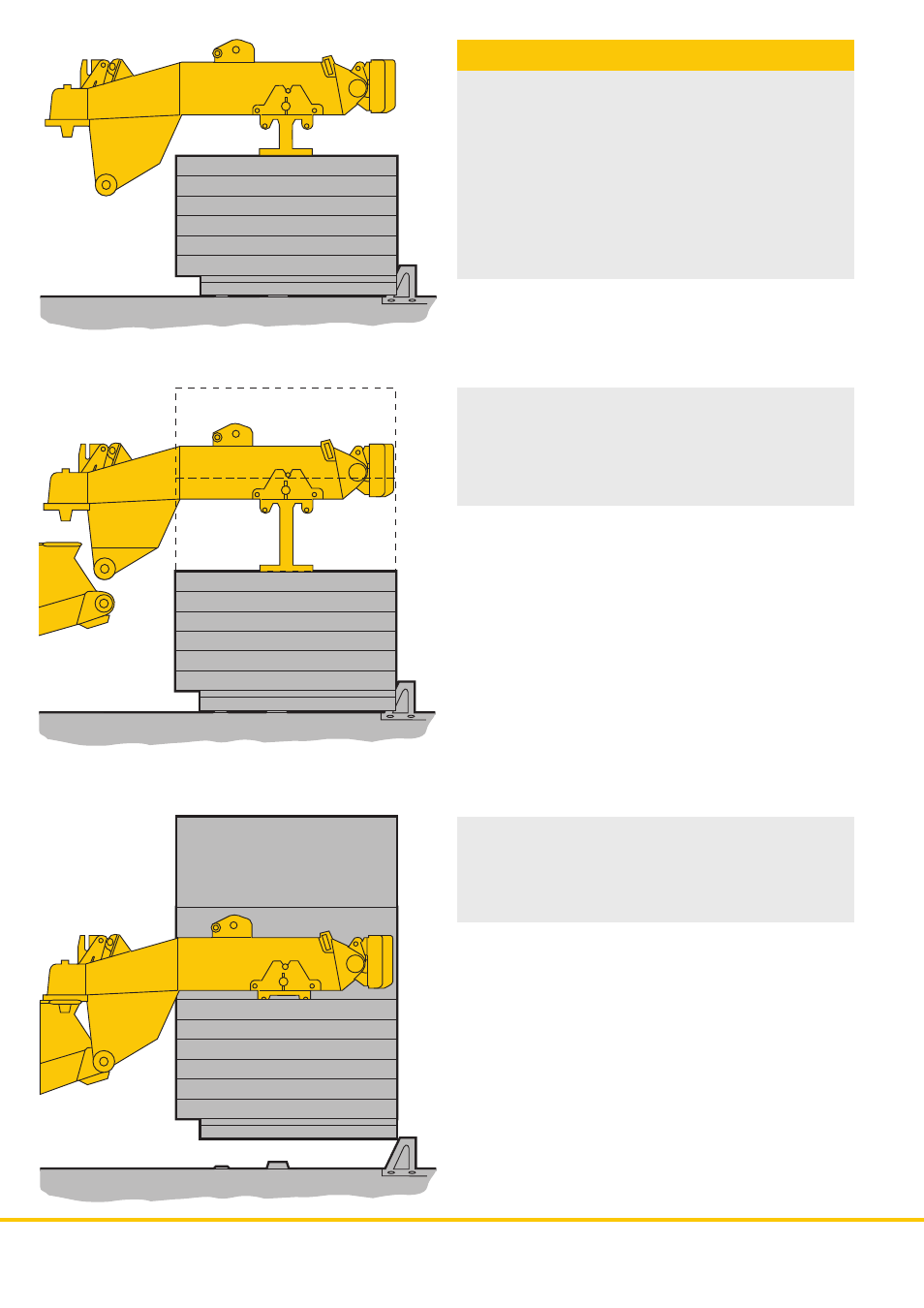

• Ballast variants of 165 t, 135 t, 105 t, 90 t, 75 t, 45 t, 30 t and

15 t, thus a considerable application spectrum

• Counterweight slabs of ideal transport dimensions

• The counterweight base slab (15 t) and 6 counterweight slabs

(15 t each) as well as the winch frame with winch 2 and 3

can be mounted as a complete unit

Counterweight erection:

• Pile up the counterweight slabs on the carrier frame, the base

slab with the ballasting rams forms the carrying plate

• Pick up the winch frame including winch 2, and winch 3 if

required, lower it into the fixing devices of the ballasting rams

and bolt it

Multivariable counterweight system

• Lower the winch frame by retracting the ballasting rams and

enter the centering pins into the location holes of the

superstructure. Continue to retract the ballasting rams and

raise the counterweight slabs until they sit close to the winch

frame

• Disconnect the hydraulic and electric connections

• Pile up the lateral counterweight slabs, depending on the

requirement (a total of 4 slabs, 15 t each)

• Connect the hydraulic devices and the remote control panel.

• Extend the ballasting rams and push the winch frame including

winches 2 and 3 upwards

• Swing superstructure into the longitudinal axis of the winch

frame