Bryant COMMERCIAL AIR COOLED CONDENSING UNITS 576b User Manual

Page 8

—

8

—

VI. ACCESSORY INSTALLATION

At this time any required accessories should be installed on

the unit. Refer to Table 5 for available accessories. Control

wiring information is provided in the unit wiring book.

Table 5 — Accessory List

PRE-START-UP

Proceed as follows to inspect and prepare the unit for initial

start-up:

1. Field electrical power source must agree with unit

nameplate rating.

2. Check voltage imbalance as shown in Table 4, Note 2.

3. Check that all internal wiring connections are tight

and that all barriers, covers, and panels are in place.

4. Ensure all service valves are open. On 576B units, be

sure all compressor service valves are backseated.

5. Verify that compressor holddown bolts have been

loosened and that flat/snubber washers can be

rotated by applying finger pressure (snug, but not

tight).

6. On 569C and 576B units, verify compressor crank-

case heater is securely in place. Crankcase heater

must operate for a least 24 hours before start-up.

7. Note that compressor oil level is visible in the sight

glass (576B units only).

8. Check for leaks in refrigerant system by using soap

bubbles and/or electronic leak detector.

9. Check that liquid line solenoid valve is located at

evaporator coil as shown in Filter Drier and Moisture

Indicator section, page 5.

10. Check that both outdoor and indoor units are prop-

erly mounted in accordance with installation instruc-

tions and applicable codes.

ACCESSORY

Gage Panel

Winter-Start Relay Package

Weatherprobe™ II Low Ambient Kit

Hail Guard Package (072)

Hail Guard Package (090,102,120)

Thermostats

Subbase

WARNING: Failure to observe the following warn-

ings could result in serious personal injury:

1. Follow recognized safety practices and wear

protective goggles when checking or servicing

refrigerant system.

2. Do not operate compressor or provide any elec-

tric power to unit unless compressor terminal

cover is in place and secured.

3. Do not remove compressor terminal cover until

all electrical sources have been disconnected.

4. If refrigerant leak is suspected around compres-

sor terminals, recover refrigerant whenever

possible and relieve all pressure from system

before touching or disturbing anything inside

terminal box.

5. Never attempt to repair soldered connection

while refrigerant system is under pressure.

6. Do not use torch to remove any component.

System contains oil and refrigerant under

pressure. To remove a component, wear protec-

tive goggles and proceed as follows:

a. Shut off electrical power to unit.

b. Recover refrigerant. Relieve all pressure

from system.

c. Cut component-connecting tubing with tub-

ing cutter and remove component from unit.

d. Carefully unsweat remaining tubing stubs

when necessary. Oil can ignite when exposed

to torch flame.

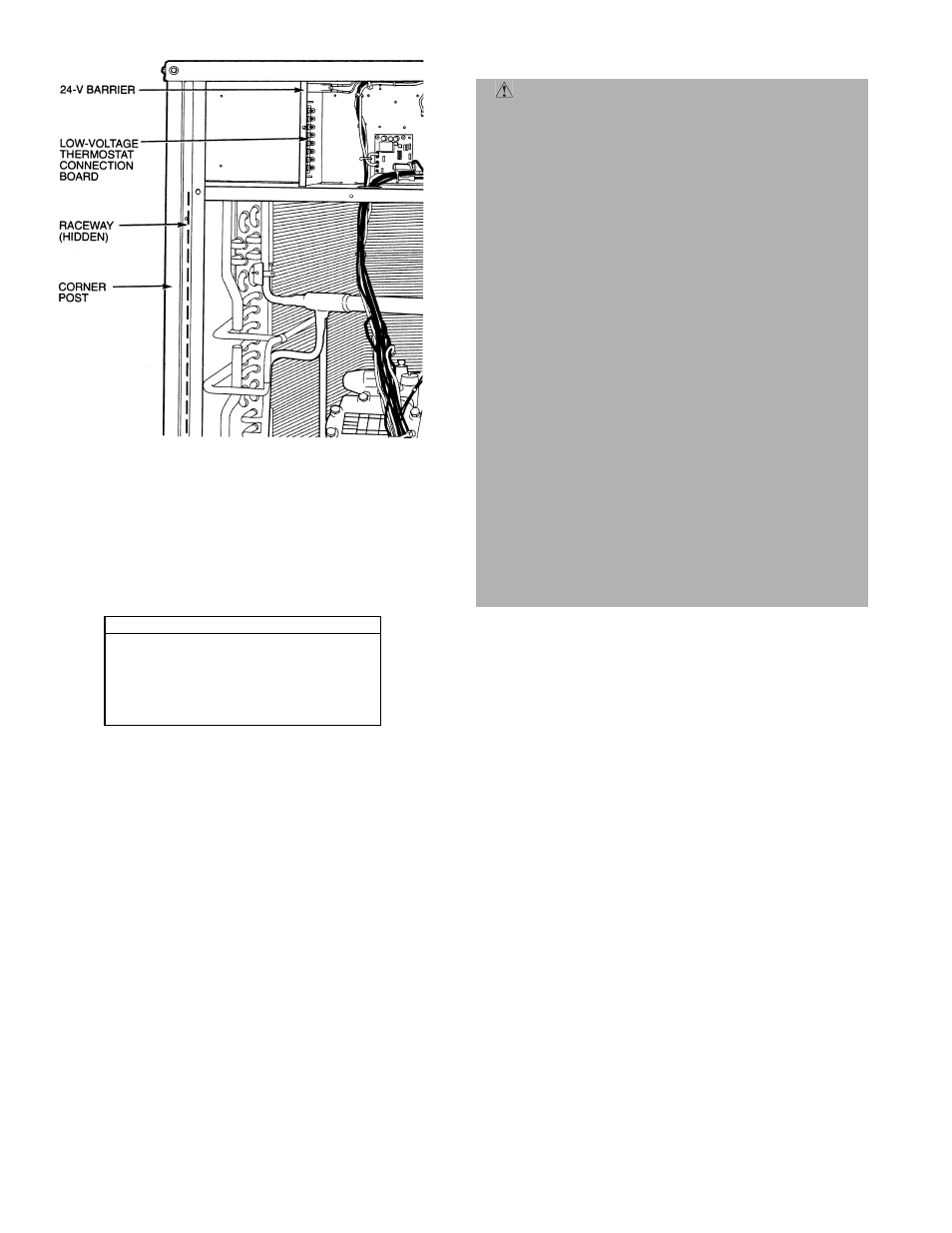

Fig. 7 — Field Control Wiring Raceway

(576B Unit Shown)