Bryant COMMERCIAL AIR COOLED CONDENSING UNITS 576b User Manual

Page 5

—

5

—

B. Filter Drier and Moisture Indicator

The filter drier is factory installed. Moisture indicator is a

field-installed accessory and should be installed just after

liquid line shutoff valve at the evaporator coil. Do not use a

receiver. A receiver is not supplied with the unit and should

not be used.

NOTE: Unit is shipped with R-22 holding charge. System

pressure must be relieved before removing caps. Recover

refrigerant prior to brazing.

Pass nitrogen or other inert gas through piping while braz-

ing to prevent formation of copper oxide.

Install field-supplied thermostatic expansion valve(s) in

evaporator section. It is recommended that a field supplied

liquid line solenoid be positioned in the main liquid line

(near the evaporator coil). It should be wired to close when

compressor stops to minimize refrigerant migration during

the ‘‘OFF’’ cycle.

Table 2 — Refrigerant Piping Sizes

LEGEND

NOTES:

1. Pipe sizes are based on a 2° F (1° C) loss for liquid and suction

lines.

2. Pipe sizes are based on the maximum linear length shown for

each column, plus a 50% allowance for fittings.

3. Charge units with R-22 in accordance with unit installation

instructions.

Table 3 — Liquid Line Data

NOTE: Values shown are for units operating at 45 F (7.2 C) saturated

suction and 95 F (35 C) entering air.

V. ELECTRICAL CONNECTIONS

A. Field Power Supply (Fig. 5-7)

1. Make all electrical connections in accordance with

NEC ANSI/NFPA (American National Standards

Institute/ National Fire Protection Association) 70,

latest edition, and local electrical codes governing

such wiring. Refer to unit wiring diagram.

2. Use only copper or copper-clad conductor fan connec-

tions between field-supplied electrical disconnect

switch and unit. DO NOT USE ALUMINUM WIRE.

Maximum wire size is no. 2 AWG (American Wire

Gage).

3. Voltage to compressor terminals during operation

must be within voltage range indicated on unit name-

plate (also see Table 4). On 3-phase units, voltages

between phases must be balanced within 2% and

LINEAR LENGTH OF PIPING — FT (M)

UNIT

0-25

(0-7.6)

25-50

(7.6-15.2)

50-75

(15.2-22.9)

75-100

(22.9-30.5)

Line Size (in. OD)

L

S

L

S

L

S

L

S

569C072

1

/

2

1

1

/

8

1

/

2

1

1

/

8

1

/

2

1

1

/

8

1

/

2

1

1

/

8

569C090

1

/

2

1

1

/

8

1

/

2

1

1

/

8

5

/

8

1

1

/

8

5

/

8

1

3

/

8

569C120

5

/

8

1

1

/

8

5

/

8

1

3

/

8

5

/

8

1

3

/

8

5

/

8

1

3

/

8

576B090

1

/

2

1

1

/

8

1

/

2

1

1

/

8

5

/

8

1

1

/

8

5

/

8

1

3

/

8

576B102

5

/

8

1

1

/

8

5

/

8

1

1

/

8

5

/

8

1

3

/

8

5

/

8

1

3

/

8

576B120

5

/

8

1

1

/

8

5

/

8

1

1

/

8

5

/

8

1

3

/

8

5

/

8

1

3

/

8

L — Liquid Line

S — Suction Line

UNIT

MAX

ALLOWABLE

LIQUID LIFT

LIQUID LINE

Max Allowable

Pressure Drop

Max Allowable

Temp Loss

Ft

M

psi

kPa

F

C

569C072

86

26.2

7

48.3

2

1

569C090

60

18.3

7

48.3

2

1

569C120

70

21.3

7

48.3

2

1

576B090

60

18.3

7

48.3

2

1

576B102

65

19.8

7

48.3

2

1

576B120

65

19.8

7

48.3

2

1

WARNING: The unit cabinet must have an

uninterrupted, unbroken electrical ground to minimize

the possibility of personal injury if an electrical fault

should occur. This ground may consist of electrical wire

connected to the unit ground lug in the control

compartment or conduit approved for electrical ground

when installed in accordance with the NEC and local

electrical codes. Failure to adhere to this warning could

result in personal injury.

CAUTION: Failure to follow these precautions

could result in damage to the unit being installed:

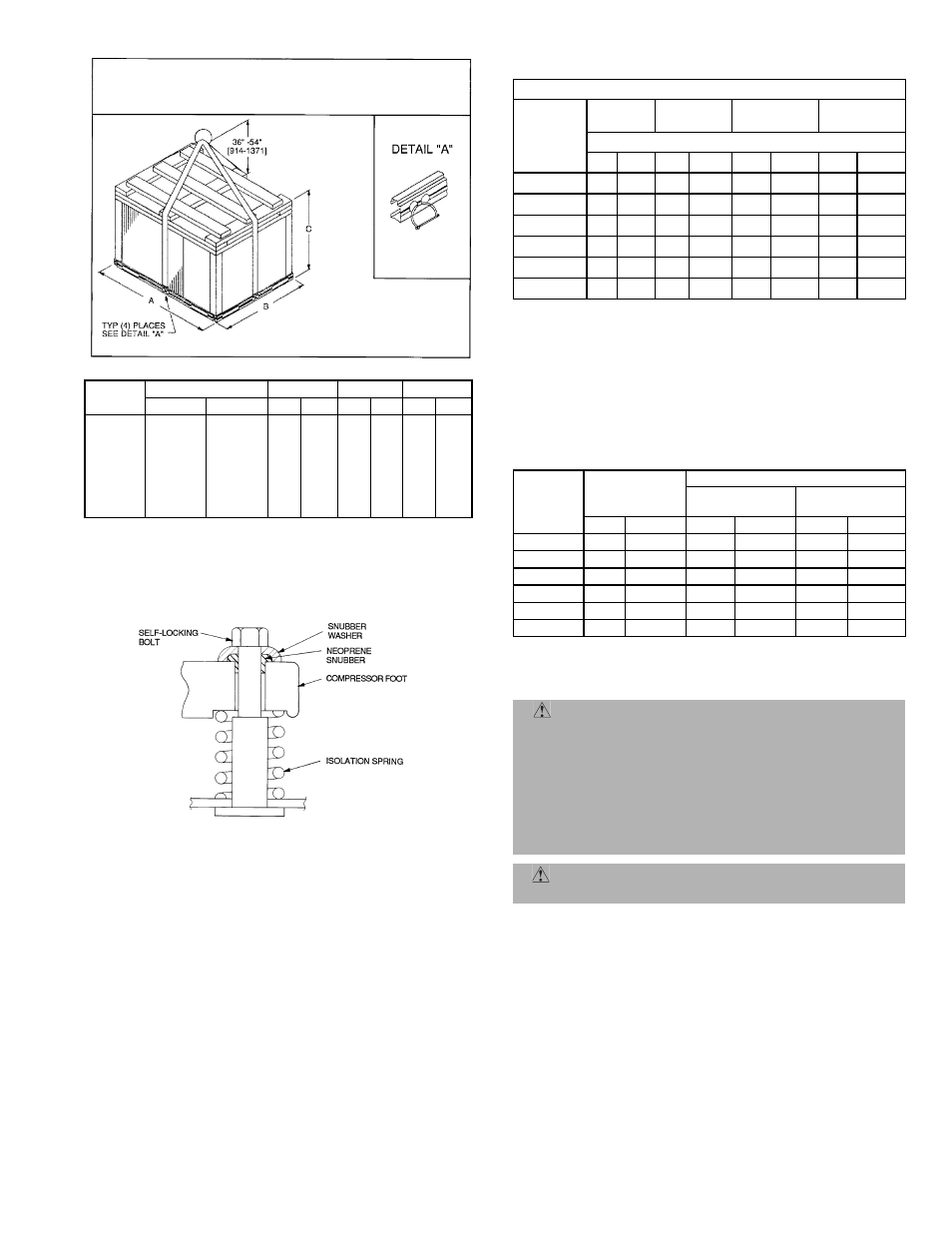

Fig. 4 — Typical Compressor Mounting (576B Units)

Fig. 3 — Rigging Label

*Weights are for aluminum coils.

UNIT

RIGGING WEIGHT*

A

B

C

lb

kg

in.

mm

in.

mm

in.

mm

569C072

390

177

45.0 1143 38.5 978 35.5

904

569C090

420

192

45.0 1143 38.5 978 43.5 1105

569C120

445

203

45.0 1143 38.5 978 43.5 1105

576B090

560

255

45.0 1143 38.5 978 43.5 1105

576B102

614

280

45.0 1143 38.5 978 43.5 1105

576B120

614

280

45.0 1143 38.5 978 43.5 1105

NOTICE TO RIGGERS

HOOK RIGGING SHACKLES THROUGH HOLES IN BASE RAIL, ON ALL FOUR SIDES.

HOLES IN BASE RAILS ARE CENTERED AROUND THE UNIT CENTER OF GRAVITY. USE

WOODEN TOP SKID, WHEN RIGGING, TO PREVENT RIGGING STRAPS FROM DAMAGING

UNIT.

CAUTION: ALL PANELS MUST BE IN PLACE WHEN RIGGING.