Bryant COMMERCIAL AIR COOLED CONDENSING UNITS 576b User Manual

Page 11

—

11

—

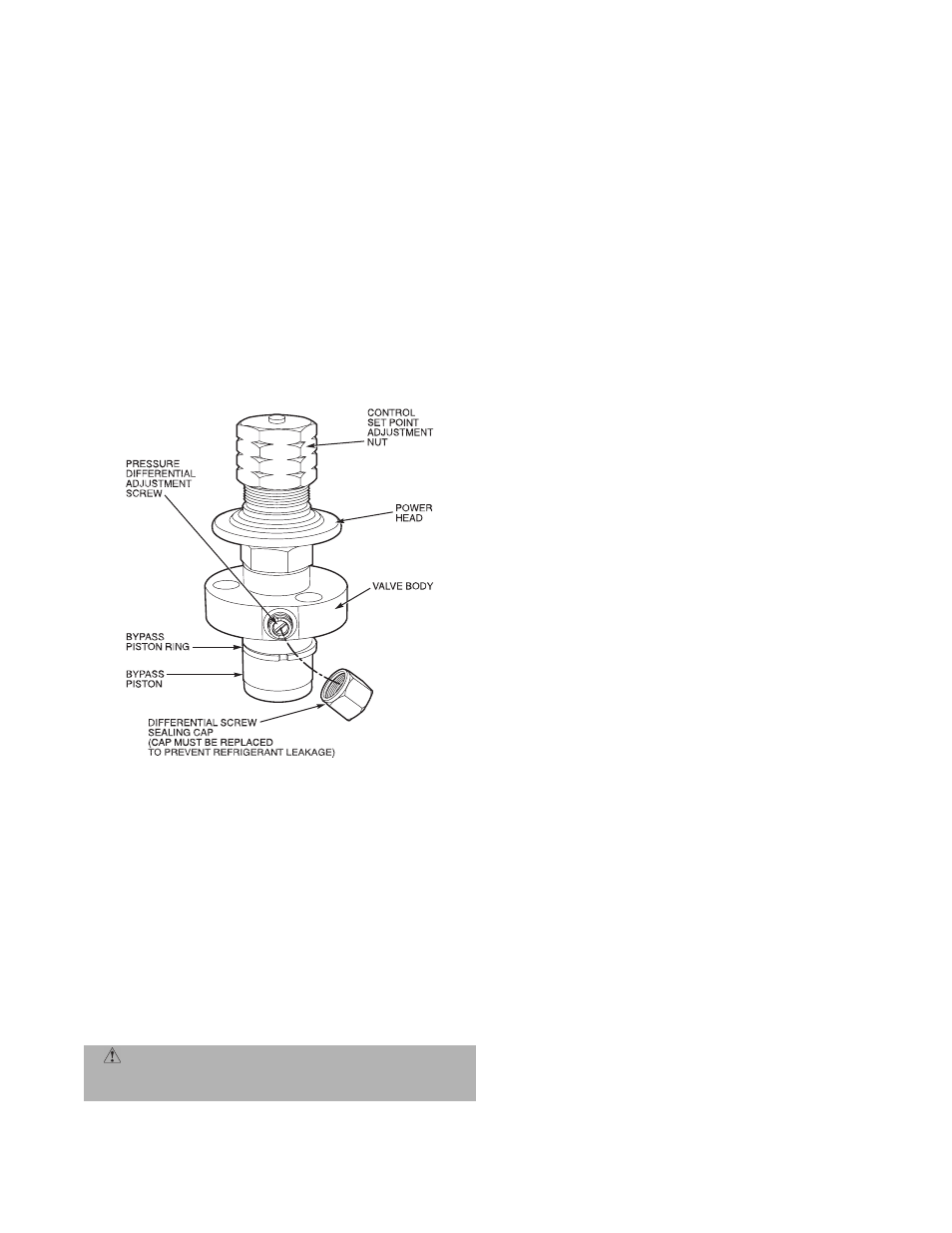

IV. CAPACITY CONTROL (576B120 Only)

A suction pressure-actuated unloader controls 2 cylinders

and provides capacity control. Unloaders are factory set (see

Table 1), but may be field adjusted:

A. Control Set Point

The control set point (cylinder load point) is adjustable from

0 to 85 psig. To adjust, turn control set point adjustment nut

(Fig. 12) clockwise to its bottom stop. In this position, set

point is 85 psig. Then, turn adjustment counterclockwise to

desired control set point. Every full turn counterclockwise

decreases set point by 7.5 psig.

B. Pressure Differential

The pressure differential (difference between cylinder load

and unload points) is adjustable from 6 to 22 psig. To adjust,

turn pressure differential adjustment screw (Fig. 12) coun-

terclockwise to its back stop position. In this position, differ-

ential is 6 psig. Then, turn adjustment screw clockwise to

desired pressure differential. Every full turn clockwise

increases differential by 1.5 psig.

V. COMPRESSOR REMOVAL

See Table 1 for compressor information.

Follow safety codes and wear safety glasses and work gloves.

1. Shut off power to unit and install lockout. Remove

unit access panel (front of unit).

2. Remove refrigerant from system using refrigerant

removal methods described in GTAC II, Module 5,

Charging, Recovery, Recycling, and Reclamation.

3. Disconnect compressor wiring at compressor termi-

nal box.

4. Remove bolts from suction flange and discharge ser-

vice valve (576B units).

5. Remove crankcase heater from compressor base

(576B units only).

6. Remove compressor holddown bolts.

7. Remove compressor from unit.

8. Clean system. Add new liquid line filter drier.

9. Install new compressor in unit.

10. Connect suction and discharge lines to compressor.

Ensure that compressor holddown bolts are in place.

11. Install crankcase heater.

12. Connect wiring.

13. Evacuate and recharge unit, per Step VII.

14. Restore unit power.

VI. CRANKCASE HEATER

The crankcase heater prevents refrigerant migration and

compressor oil dilution during shutdown when compressor is

not operating.

Close both compressor service valves if applicable when

crankcase heater is deenergized for more than 6 hours.

VII. REFRIGERANT CHARGE

Unit panels must be in place when unit is operating during

charging procedure. Unit is shipped with a holding charge

only. Weigh in 7 lbs of R-22 to start unit. Refer to GTAC II,

Module 5, Charging, Recovery, Recycling, and Reclamation

for additional information.

See Troubleshooting Guide on page 13 for additional

information.

A. Low Charge Cooling

Using Cooling Charging Charts, Fig. 13 and 14, vary refrig-

erant until the conditions of the appropriate chart are met.

Note the charging charts are different from type normally

used. The charts are based on charging the units to the cor-

rect sub-cooling for the various operating conditions. Accu-

rate pressure gage and temperature sensing device are

required.

Connect the pressure gage to the service port on the liquid

line service valve. Mount the temperature sensing device on

the liquid line, close the liquid line service valve, and insu-

late it so that outdoor ambient temperature does not affect

the reading. Indoor-air cfm must be within the normal oper-

ating range of the unit.

Operate unit a minimum of 15 minutes. Ensure that temper-

ature and pressure have stabilized. Plot liquid pressure and

temperature on chart and add or reduce charge as required.

Do not vent refrigerant to the atmosphere. Recover any

excess charge. Operate the unit until the system stabilizes.

Adjust charge to conform with charging chart, using liquid

pressure and temperature to read chart.

B. Refrigerant Leaks

Proceed as follows to repair a refrigerant leak and to charge

the unit:

1. Locate the leak and ensure that refrigerant system

pressure has been relieved.

2. Repair leak following accepted practices.

NOTE: Install a new filter drier in the liquid line whenever

the system has been opened for repair.

3. Add a small charge of R-22 refrigerant vapor to sys-

tem and leak-test unit.

4. Evacuate refrigerant system up to 500 micons. If

additional leaks are not found.

5. Charge unit with R-22 refrigerant.

NOTE: Do not vent refrigerant to the atmosphere. Recover

any excess charge.

CAUTION: Excessive movement of copper lines at

compressor may cause higher levels of vibration when

unit is restored to service.

Fig. 12 — Compressor Capacity Control Unloader