Graphic, For position of the inlet connection refer, Preparing to install – Neff T22S46N0 User Manual

Page 6: To change injectors, Table, Table heading, Table row, Natural gas, Universal lpg, Burner

6

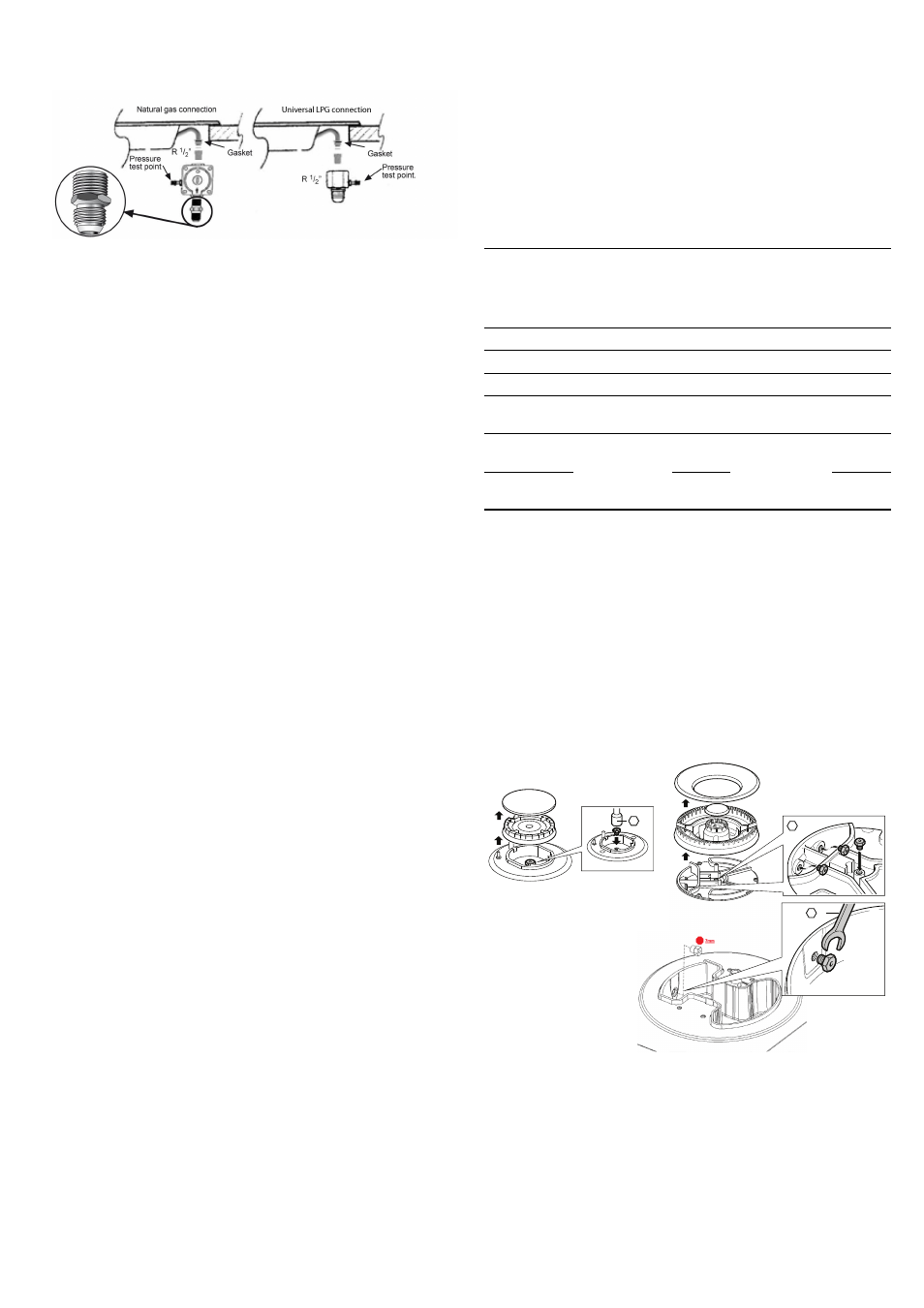

Fit regulator (N.G.) or a test point (Universal LPG) directly to the

R 1/2’’ connection.

Direction of gas flow is indicated on the rear of the regulator.

For position of the inlet connection refer Preparing to install.

Use pipe compound or thread sealant, properly theaded pipes

and careful assembly procedure so that there is no cross

threading, etc., which might cause damage or leakage.

Make sure that all connections peformed are free of leakage.

The manufacturer does not accept any liability for leakage on

connections performed by the installer or if the L-tube is moved

or twisted.

There are two ways to carry out the connection to the main gas

line:

■

The hotplate can be connected with rigid pipe as specified in

AS/NZS 5601.1

■

Flexible Hose: If installing with a hose assembly, it must

comply with AS/NZS 1869, 10 mm ID, class B or D, no more

than 1.2 m long and installed in accordance with AS/NZS

5601.1.

Ensure that the hose does not contact the hot surfaces of the

hotplate, oven, dishwasher or any other appliance that may

be installed underneath or next to the hotplate. The hose

should not be subjected to abrasion, kinking or permanent

deformation and should be able to be inspected along its

entire length with the cooktop in the installed position. Unions

compatible with the hose fittings must be used and all

connections tested for gas leaks.

The supply connection point shall be accessible with the

appliance installed.

WARNING: Ensure that the hose assembly is restrained from

accidental contact with the flue outlet of an underbench oven.

Before Leaving- Check all connections for gas leaks with soap

and water. DO NOT use a naked flame for detecting leaks.

Ignite all burners both individually and concurrently to ensure

correct operation of gas valves, burners and ignition. Turn gas

taps to low flame position and observe stability of the flame for

each burner individually and all together. Adhere the duplicate

data plate to an accessible location near the hotplate. When

satisfied with the hotplate, please instruct the user on the

correct method of operation. In case the appliance fails to

operate correctly after all checks have been carried out, refer to

the authorised service provider in your area.

It should be expressly noted that we cannot accept any liability

for direct or indirect damage caused by wrong connection,

leakage or improper installation. When being repaired, the

appliance must always be disconnected from the mains supply;

if required, notify our customer service.

Converting the cooktop from Nat. Gas to

Universal LPG

To change injectors

All work involved in installation, setting and adaptation to a

different gas type must be carried out by authorised personnel

from our Service Centre and must comply with current

regulations and the conditions laid down by the local gas

company.

Request change-over injectors from our customer service

deparment (refer injector chart below for sizes).

Before conversion the cooktop must be disconnected from the

electricity and gas valves must be turned to the OFF position.

Changing the nozzles of the burners on the

cooktop

1.

Remove the pan supports, burner covers and diffusers.

2.

Change the nozzles using the spanner provided by our

Service Centre (code 340847, for double and triple flame

burners code 340808), taking special care to ensure that the

nozzle does not fall when it is removed from the burner or

when fitted.

Ensure that it is completely tightened in order to guarantee

the seal.

Natural Gas

Universal LPG

Burner

Hourly Gas

Consumption

(MJ)

Injector

mark

Hourly Gas

Consumption

(MJ)

Injector

mark

Auxiliary

3,60

90

3,50

50

Semi-rapid

6,50

118

6,00

67

Rapid

10,80

155

10,00

85

Double

flame

12,00

160

11,00

91

Dual double

flame (inner)

18,00

85

18,00

46

Dual double

flame (outer)

140

71