Bryant Gas Heating/Electric Cooling Units 581B User Manual

Page 8

Table 2 — Maximum Gas Flow Capacity of Pipe in Cubic Ft of Gas Per Hour

for Gas Pressures of 0.5 Psig or Less and a Pressure Drop of 0.5 in. wg

(Based on a 0.60 Specific Gravity Gas)

NOMINAL

IRON PIPE

SIZE

(in.)

INTERNAL

DIAMETER

(in.)

LENGTH OF PIPE, FT*

10

20

30

40

50

60

70

80

90

100

125

150

175

200

1

⁄

2

.622

175

120

97

82

73

66

61

57

53

50

44

40

—

—

3

⁄

4

.824

360

250

200

170

151

138

125

118

110

103

93

84

77

72

1

1.049

680

465

375

320

285

260

240

220

205

195

175

160

145

135

1

1

⁄

4

1.380

1400

950

770

600

580

530

490

460

430

400

360

325

300

280

1

1

⁄

2

1.610

2100

1460

1180

990

900

810

750

690

650

620

550

500

460

430

Refer to Table 10-2, National Fire Protection Association (NFPA), latest edition.

*This length includes an ordinary number of fittings.

NOTE: Typical natural gas heating value is 1000 Btuh per cubic ft.

115,000

For example: A 115,000 Btuh input unit equals 115 cubic ft per hour or

= 115 cubic ft/hr.

1,000

When installing the gas supply line, observe local codes per-

taining to gas pipe installations. Refer to the NFGC ANSI

Z223.1-1992 (in Canada, CAN/CGA B149.1, [2]-M86) or NFPA

54-1992, in the absence of local building codes. Adhere to the

following pertinent recommendations:

1. Avoid low spots in long runs of pipe. Grade all pipe

1

⁄

4

inch in every 15 ft to prevent traps. Grade all hori-

zontal runs downward to risers. Use risers to connect to

heating section and to meter.

2. Protect all segments of piping system against physical

and thermal damage. Support all piping with appropri-

ate straps, hangers, etc. Use a minimum of one hanger

every 6 ft. See Fig. 10. For pipe sizes larger than

1

⁄

2

in.,

follow recommendations of national codes.

3. Apply joint compound (pipe dope) sparingly and only to

male threads of joint when making pipe connections. Use

only pipe dope that is resistant to action of liquefied pe-

troleum gases as specified by local and/or national codes.

Never use Teflon-coated tape.

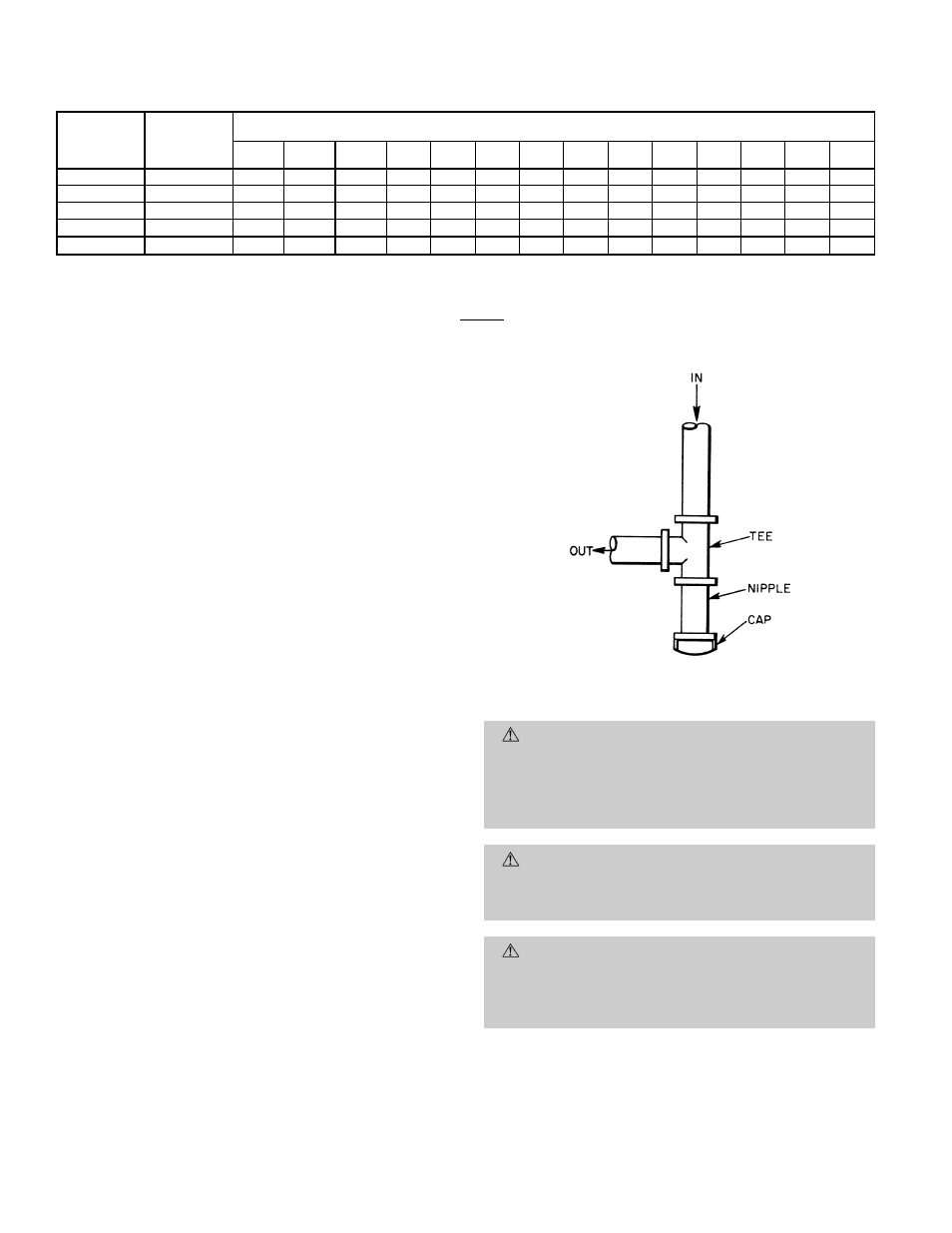

4. Install sediment trap in riser leading to heating sec-

tion. This drip leg functions as a trap for dirt and con-

densate. Install trap where condensate can not freeze.

Install this sediment trap by connecting a piping tee to

riser leading to heating section, so that straight-

through section of tee is vertical. See Fig. 11. Then, con-

nect capped nipple into lower end of tee. Extend capped

nipple below level of gas controls.

5. Install an accessible, external, manual main shut-off valve

in gas supply pipe within 6 ft of heating section.

6. Install ground-joint union close to heating section be-

tween unit manual shutoff and external manual main

shut-off valve.

7. Pressure-test all gas piping in accordance with local and

national plumbing and gas codes before connecting pip-

ing to unit.

NOTE:

When pressure testing the gas supply system after

the gas supply piping has been connected to the unit gas valve,

the supply piping must be disconnected from the gas valve

during any pressure testing of the piping systems at test pres-

sure in excess of 0.5 psig. When pressure testing the gas sup-

ply piping system at test pressures equal to or less than

0.5 psig, the unit heating section must be isolated from the

gas piping system by closing the external main manual shut-

off valve and slightly opening the ground-joint union. After

pressure test is completed, retighten ground-joint union.

CAUTION:

Unstable operation may occur when the

gas valve and manifold assembly are forced out of po-

sition while connecting improperly routed rigid gas pip-

ing to the gas valve. Use a backup wrench when mak-

ing connection to avoid strain on, or distortion of, the

gas control piping.

CAUTION:

If a flexible conductor is required or al-

lowed by the authority having jurisdiction, black iron

pipe shall be installed at the gas valve and extend a

minimum of 9 in. outside the unit casing.

WARNING:

Never use a match or other open flame

when checking for gas leaks. Never purge gas line into

combustion chamber. Failure to adhere to this warning

could result in an explosion causing personal injury or

death.

8. Check for gas leaks at all field- and factory-installed gas

lines after all piping connections have been completed.

Use soap-and-water solution (or method specified by lo-

cal codes and/or regulations).

Fig. 11 — Sediment Trap

—8—