Bryant Gas Heating/Electric Cooling Units 581B User Manual

Page 30

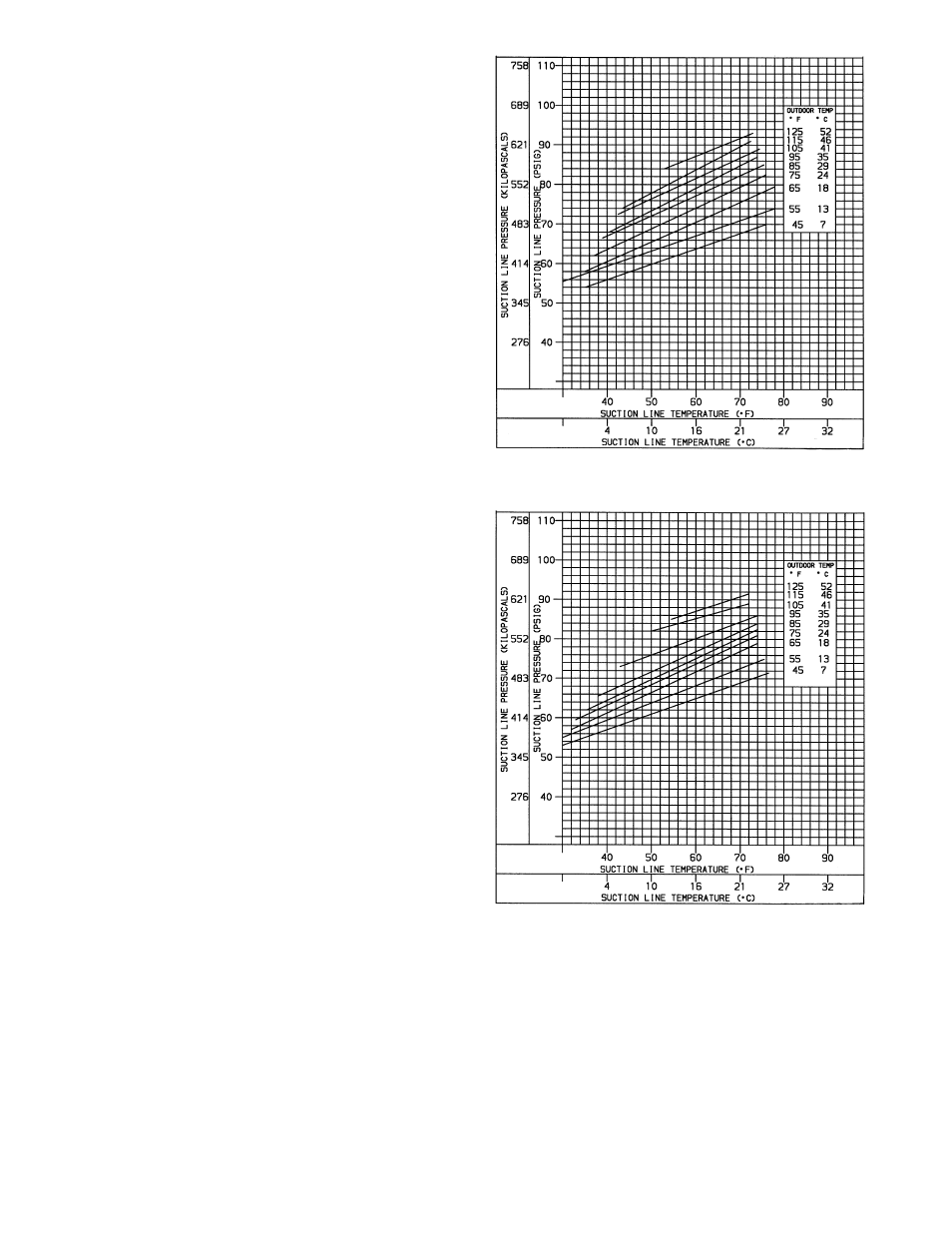

B. Low Charge Cooling

Using Cooling Charging Charts, Fig. 39-42, vary refrigerant

until the conditions of the appropriate chart are met. Note

the charging charts are different from type normally used.

Charts are based on charging the units to the correct super-

heat for the various operating conditions. Accurate pressure

gage and temperature-sensing device are required. Connect

the pressure gage to the service port on the suction line. Mount

the temperature-sensing device on the suction line and insu-

late it so that outdoor ambient temperature does not affect

the reading. Indoor-air cfm must be within the normal oper-

ating range of the unit.

C. To Use Cooling Charging Charts

Take the outdoor ambient temperature and read the suction

pressure gage. Refer to appropriate chart to determine what

suction temperature should be. If suction temperature is high,

add refrigerant. If suction temperature is low, carefully re-

claim some of the charge. Recheck the suction pressure as

charge is adjusted.

EXAMPLE:

(Fig. 41)

Outdoor Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 F

Suction Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74 psig

Suction Temperature should be . . . . . . . . . . . . . . . . . . . 48 F

(Suction Temperature may vary ± 5 F.)

D. Refrigerant Leaks

Proceed as follows to repair a refrigerant leak and to charge

the unit:

1. Locate leak and ensure that refrigerant system pres-

sure has been relieved.

2. Repair leak following accepted practices.

NOTE:

Replace filter drier in the liquid line whenever the

system has been opened for repair.

3. Add a small charge of R-22 refrigerant vapor to system

and leak-test unit.

4. Evacuate refrigerant system if additional leaks are not

found.

5. Charge unit with R-22 refrigerant, using a volumetric-

charging cylinder or accurate scale. Refer to unit rating

plate for required charge. Be sure to add extra refriger-

ant to compensate for internal volume of filter drier.

VI. MAIN BURNERS

At the beginning of each heating season, inspect for deterio-

ration or blockage due to corrosion or other causes. Observe

the main burner flames and adjust if necessary.

VII. FLUE GAS PASSAGEWAYS

To inspect the flue collector box and upper areas of the heat

exchanger:

1. Remove the combustion blower wheel and motor assem-

bly according to directions in Combustion-Air Blower sec-

tion below.

2. Remove the 3 screws holding the blower housing to the

flue cover.

3. Remove the flue cover to inspect the heat exchanger.

4. Clean all surfaces as required using a wire brush.

VIII. COMBUSTION-AIR BLOWER

Clean periodically to ensure proper airflow and heating effi-

ciency. Inspect blower wheel every fall and periodically dur-

ing heating season. For the first heating season, inspect blower

wheel bimonthly to determine proper cleaning frequency.

To inspect blower wheel, remove draft hood and screen. Shine

a flashlight into opening to inspect wheel. If cleaning is re-

quired, remove motor and wheel as follows:

1. Slide burner access panel out.

2. Remove the 2 screws which hold the heat shield in place,

and remove heat shield.

3. Remove the 7 screws that attach induced-draft motor

mounting plate to blower housing (Fig. 43).

Fig. 39 — Cooling Charging Chart, 581B036

Fig. 40 — Cooling Charging Chart, 581B048

—30—