Bryant Gas Heating/Electric Cooling Units 581B User Manual

Page 19

Table 5 — Rated Gas Inputs at Indicated Manifold Pressures

UNIT

581B

NUMBER

OF

ORIFICES

GAS SUPPLY PRESSURE

(in. wg)

MANIFOLD

PRESSURE

(in. wg)

NATURAL GAS

PROPANE*

Natural

Propane

Orifice

Drill Size

Heating Input

(Btuh)†

Orifice

Drill Size

Heating Input

(Btuh)†

Min

Max

Min

Max

Natural

Propane

036-072**

2

4.0

13.6

5.0

13.0

3.5

3.5

33

72,000

43

72,000

3

4.0

13.6

5.0

13.0

3.5††

3.5††

33

115,000††

43

115,000††

3

5.0

13.6

5.0

13.0

3.5

3.5

30

150,000

38

150,000

*When a 581B unit is converted to liquid propane (LP), the burners must be modified with accessory LP Kit.

†Based on altitudes from sea level up to 2000 ft above sea level. For altitudes above 2000 ft, reduce input rating 4% for

each 1000 ft above sea level. In Canada, from 2000 ft above sea level to 4,500 ft above sea level, derate the unit 10%.

**581B036 with 150,000 Btuh input not available.

††581B036115 at high fire operation. At low fire, manifold pressure is 1.8 in. wg, and heating input is 82,000 Btuh.

581B048-072150 at high fire operation. At low fire, manifold pressure is 2.2 in. wg, and heating input is 120,000 Btuh.

Table 6 — Altitude Compensation* — Units 581B036-072

ELEVATION

(ft)

72,000 AND 115,000

BTUH NOMINAL INPUT

150,000 BTUH

NOMINAL INPUT

Natural

Gas

Orifice

Size†

Liquid

Propane

Orifice

Size†

Natural

Gas

Orifice

Size†

Liquid

Propane

Orifice

Size†

0-2,000

33

43

30

38

2,000

34

43

30

39

3,000

35

44

31

40

4,000

36

44

32

41

5,000

36

44

33

42

6,000

37

45

34

43

7,000

37

45

35

43

8,000

38

46

36

44

9,000

39

47

37

44

10,000

41

48

38

45

11,000

43

48

39

45

12,000

44

49

40

46

13,000

44

49

41

47

14,000

45

50

42

47

*As the height above sea level increases, there is less oxygen per cubic

foot of air. Therefore, heat input rate should be reduced at higher

altitudes.

†Orifices are available through your local distributor or branch.

NOTE:

The gas manifold is equipped with a plug located ap-

proximately 5 in. down from the gas valve which may also be

used to connect the manometer.

3. Record number of seconds for gas meter test dial to make

one revolution.

4. Divide number of seconds in Step 3 into 3600 (number

of seconds in 1 hour).

5. Multiply result of Step 4 by the number of cubic ft shown

for one revolution of test dial to obtain cubic ft of gas

flow per hour.

6. Multiply result of Step 5 by Btu heating value of gas to

obtain total measured input in Btuh. Compare this value

with heating input shown in Table 1. (Consult the local

gas supplier if the heating value of gas is not known.)

EXAMPLE:

Assume that the size of test dial is 1 cubic ft, one

revolution takes 33 seconds, and the heating value of the gas

is 1050 Btu/ft

3

, then proceed as follows:

1. 33 seconds to complete one revolution.

2. 3600

Ϭ 33 = 109

3. 109 x 1 = 109 ft

3

of gas flow/hr

4. 109 x 1050 = 114,450 Btuh input

If the desired gas input is 115,000 Btuh, only a minor change

in the manifold pressure is required.

Observe manifold pressure and proceed as follows to adjust

gas input:

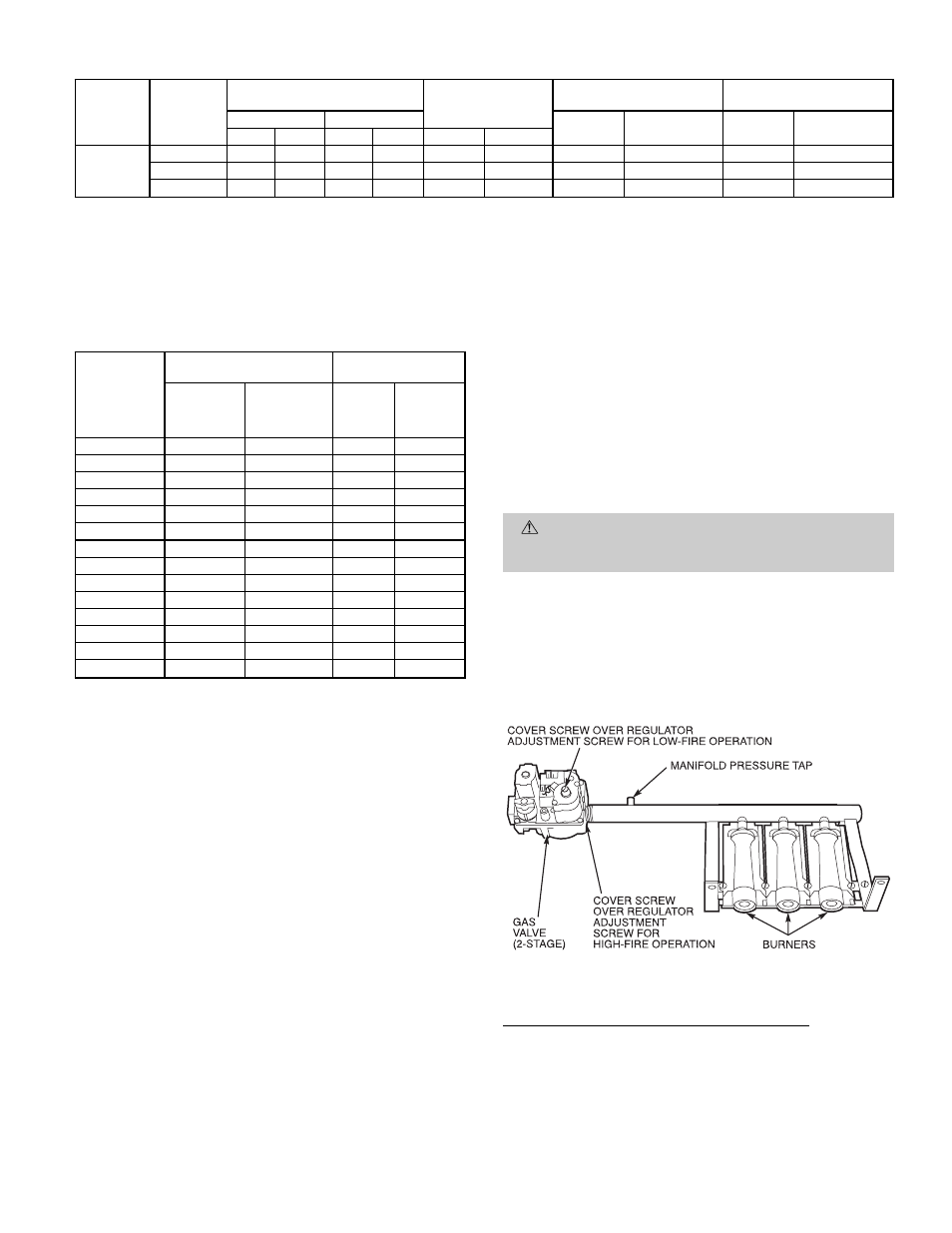

1. Remove cover screw over regulator adjustment screw on

gas valve. See Fig. 31.

2. Turn regulator adjustment screw clockwise to increase

gas input, or turn regulator adjustment screw counter-

clockwise to decrease input. Manifold pressure must be

between 3.2 and 3.8 in. wg on high-fire, two-stage units.

WARNING:

Unsafe operation of the unit may result

if manifold pressure is outside this range. Personal in-

jury or unit damage may result.

3. Replace cover screw cap on gas valve.

4. Turn off gas supply to unit.

5. Remove manometer from pressure tap.

6. Replace pipe plug on gas valve or manifold.

7. Turn on gas to unit.

8. Check for leaks.

Measuring Manifold Pressure — LP Gas Units

The main burner orifices on LP gas unit are sized for the unit

rated input when the manifold pressure is 3.5 in. wg (high-

fire on two-stage units).

Proceed as follows to adjust gas input on an LP gas unit:

1. Turn off gas to unit.

2. Remove pipe plug on outlet of gas valve or manifold.

3. Connect manometer.

Fig. 31 — Burner Tray Details

—19—