Bryant 541A User Manual

Page 7

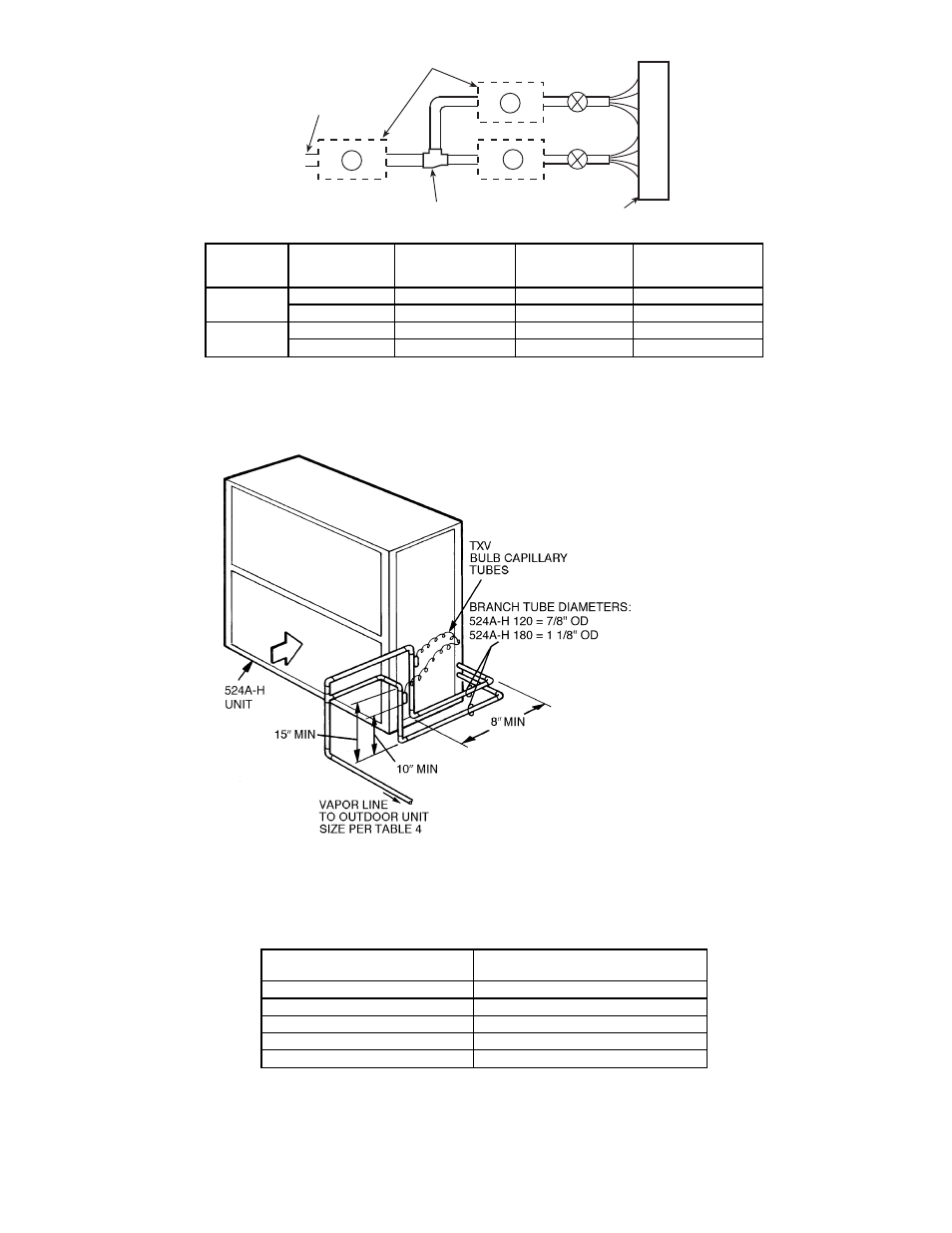

Table 5 — Insulation for Vapor Line Exposed to Outdoor Conditions

LENGTH OF EXPOSED

VAPOR LINE*

INSULATION THICKNESS†

ft

in.

10

3

⁄

8

25

1

⁄

2

35

3

⁄

4

50

3

⁄

4

*Recommended vapor line insulation for piping exposed to outdoor conditions to

prevent loss of heating during heating cycle. When vapor line goes through inte-

rior spaces, insulation should be selected to prevent condensation on cooling cycle.

Heating capacity should be reduced 1000 Btuh if over 35 ft of vapor line with

3

⁄

4

in. insulation is exposed to outdoor conditions.

†Closed cell foam insulation with a thermal conductivity of:

0.28 Btu • in/ft

2

• h • °F.

LIQUID LINE

BI-FLOW FILTER DRIER

TXV

REDUCING TEE

INDOOR COIL

B

A

A

UNIT

541A

LIQUID

LINE

SIZE (in.)

PART NO.

QUANTITY

REQUIRED

FIGURE

REFERENCE

120

1

⁄

2

P504-8084S

2

A

5

⁄

8

P504-8165S

1

B

180

1

⁄

2

P504-8084S

2

A

5

⁄

8

P504-8085S

2

A

LEGEND

TXV — Thermostatic Expansion Valve

Fig. 6 — Recommended Filter Driers and Installation Locations

Fig. 7 — Vapor Line Branch Piping Details

LEGEND

TXV — Thermostatic Expansion Valve

—7—