Bryant 541A User Manual

Page 2

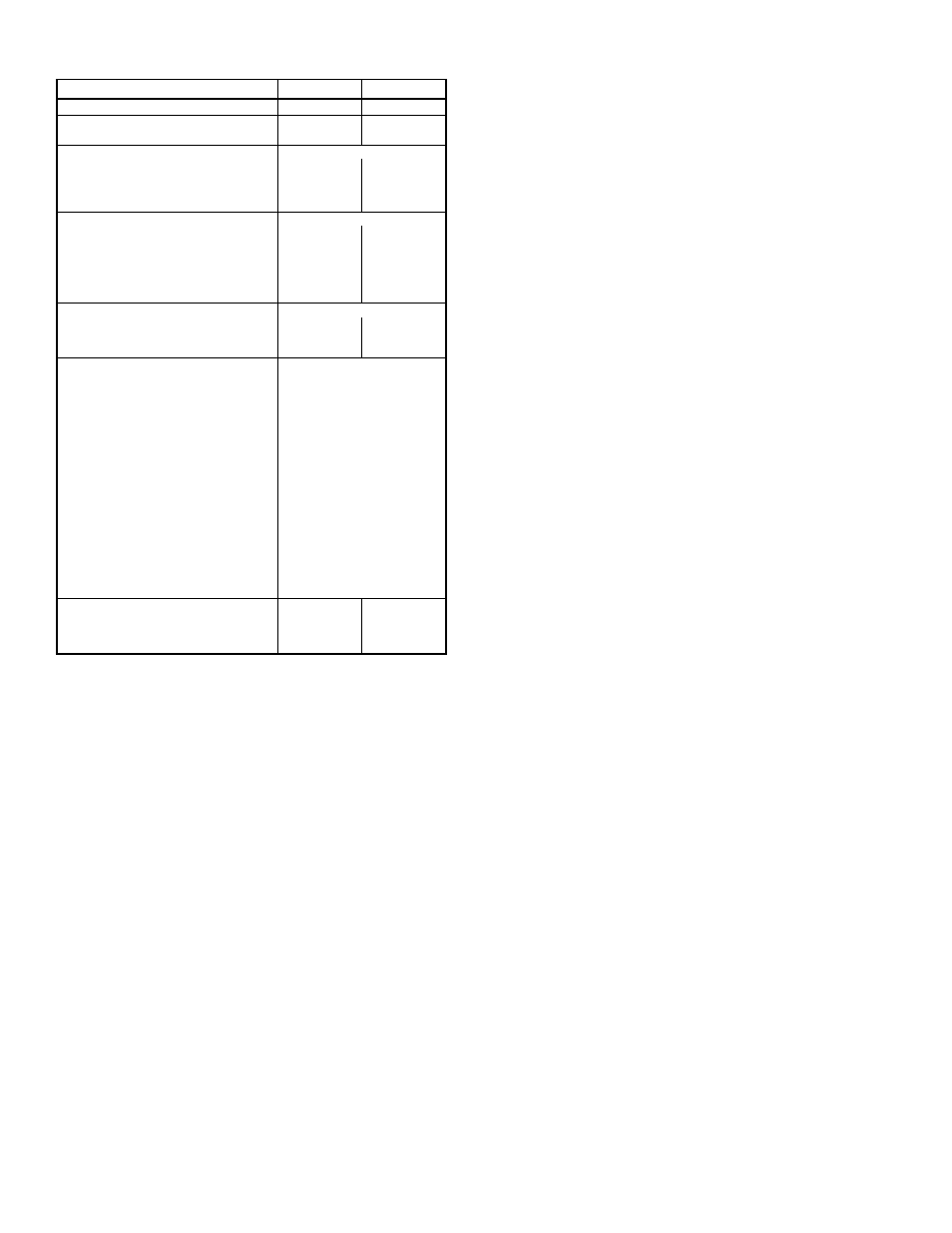

Table 1 — Physical Data

UNIT 541A

120

180

OPERATING WEIGHT (lb)

750

803

REFRIGERANT

R-22

R-22

Operating Charge (lb)*

30

37

COMPRESSOR

Recip Hermetic; 1750 Rpm

Model No.

06DF824

06DF537

Cylinders

6

6

Oil (pts)

10

10

Crankcase Heater (Watts)

180

180

OUTDOOR AIR FANS

Direct Drive — Axial Flow

Number

2

2

Speed (rpm)

1075

1075

Diameter (in.)

26

26

Motor Hp

1

⁄

2

1

⁄

2

Airflow (cfm)

11,000

11,000

kW (total)

1.46

1.46

OUTDOOR COIL

Plate Fins; 15 Per Inch

Rows Deep

2

3

Face Area (sq ft)

29.2

29.2

Storage Capacity (lb)†

27.2

40.1

CONTROLS

High-Pressure Switch (HPS)

Cutout (psig)

400

Cut-in (psig)

300

Loss-of-Charge Switch

(Liquid Line)

Cutout (psig)

7

Ϯ

3

Cut-in (psig)

22

Ϯ

5

Head Pressure

(No. 2 Fan Cycling)**

Opens (psig)

160 ± 10

Closes (psig)

255 ± 10

Oil Pressure Switch (Differential)

Set Point (psig)

(Close on Rise)

9.5

Ϯ

1

(Open on Fall)

5

Defrost Pressure Switch (HPS2)

Opens (psig)

280

Ϯ

10

Closes (psig)

180

Ϯ

2

THERMOSTAT

Defrost Switch

Opens (F)

65

80

Closes (F)

27

27

*Approximate charge with 25 ft of interconnecting piping. Use

appropriate charging charts for actual charging of unit.

†Refrigerant storage capacity at 120 F condensing temperature with

condenser 80% full of liquid.

**Head pressure control on cooling cycle only.

B. Locate Unit

For service access and unrestricted airflow, provide 2 ft clear-

ance on each end of unit and 3 ft clearance on each side of

unit. Position unit so that there is unrestricted airflow above

unit.

NOTE:

Before mounting unit, remove 4 holddown brackets

and release skid.

If conditions or local codes require unit to be fastened to

pad, use the mounting holes in the 4 unit mounting feet (see

Fig. 1).

C. Mount Unit

The unit may be mounted on a solid, level concrete pad, on

accessory mounting legs, or on field-supplied raised supports

at each mounting position. (Note that mounting hardware is

field supplied.)

Weight distribution (shown in Fig. 3 and Table 2) determines

the type of support required. Bolt unit securely to pad or sup-

ports after unit is in position and is level. Be sure to mount

unit level to ensure proper oil return to compressors. Mount-

ing holes on unit can be used to secure unit to vibration iso-

lators, if required.

D. Compressor Mounting

As shipped, compressor is held down by 4 bolts. After unit is

installed, loosen each bolt using locknut shown in Fig. 4 un-

til flat washer (

3

⁄

8

in.) can be moved with finger pressure.

III. STEP 3 — COMPLETE REFRIGERANT PIPING

CONNECTIONS

Refrigerant lines must be carefully designed and constructed

to ensure equipment reliability and efficiency. Line length,

pressure drop, compressor oil return, and vertical separation

are several of the design criteria that must be evaluated. See

the following sections.

IMPORTANT:

Piping must be properly sized and installed for

the system to operate efficiently.

A. Check Vertical Separation

If there is any vertical separation between the indoor and out-

door units, check Table 3 to ensure that the separation is within

allowable limits. Relocate equipment if necessary.

—2—