Bryant 541A User Manual

Page 12

START-UP

Compressor crankcase heater must be on for 24 hours

before start-up. To energize the crankcase heater, set the space

thermostat above the ambient temperature so there is no

demand for cooling. Close the field disconnect. Leave the com-

pressor circuit breaker off/open. The crankcase heater is now

energized.

After the heater has been on for 24 hours, the unit can be

started. If no time has elapsed since the preliminary charge

step was completed, it is unnecessary to wait the 24-hour

period.

I. PRELIMINARY CHECKS

1. Ensure that compressor service valves are backseated.

2. Verify that the compressor floats freely on its mounting

springs.

3. Check that electric power supply agrees with unit name-

plate data.

4. Verify that compressor crankcase heater is securely in

place.

5. Check that compressor crankcase heater has been on at

least 24 hours.

6. Check to see if compressor oil level is visible in the sight

glass. If oil level adjustment is required, see the follow-

ing Preliminary Oil Charge section.

7. Recheck for leaks using same procedure as previously

outlined in Pre-Start-Up section, Leak Test and Dehy-

dration, page 10.

8. If any leaks are detected, evacuate and dehydrate as pre-

viously outlined in Pre-Start-Up section, Leak Test and

Dehydration, page 10.

II. PRELIMINARY OIL CHARGE

The compressor is factory charged with oil (see Table 1). When

oil is checked at start-up, it may be necessary to add or re-

move oil to bring it to the proper level. One recommended oil

level adjustment method is as follows:

A. Add Oil

Close suction service valve and pump down crankcase to

2 psig. Wait a few minutes and repeat until pressure re-

mains steady at 2 psig. Remove oil fill plug above the sight

glass, add oil through plug hole, and replace plug. Run com-

pressor for 20 minutes and check oil level.

NOTE:

Use only approved compressor oil. Approved sources

are:

Petroleum Specialties Inc. . . . . . . . . . . . . . . . . . . Cryol 150A

Texaco, Inc. . . . . . . . . . . . . . . . . . . . . . . . . . . . Capella WF-32

Witco Chemical Co. . . . . . . . . . . . . . . . . . . . . . . . Suniso 3GS

Do not use oil that has been drained out, or oil that has been

exposed to atmosphere.

B. Remove Oil

Pump down compressor to 2 psig. Loosen the

1

⁄

4

-in. pipe plug

at the compressor base and allow the oil to seep out past the

threads of the plug. Retighten plug when level is correct.

NOTE:

The crankcase is slightly pressurized. Do not

remove the plug, or the entire oil charge will be lost.

Small amounts of oil can be removed through the oil pump

discharge connection while the compressor is running.

III. START UNIT

Close the field disconnect and set the space thermostats above

ambient temperature so that there is no demand for cooling.

Only the crankcase heaters will be energized.

Next, close the compressor circuit breakers. Place thermo-

stat selector switch at COOL and set space set point below

ambient temperature so that a call for cooling is ensured. If

compressor does not start, set thermostat lower.

NOTE:

Do not use circuit breaker to start and stop the com-

pressor except in an emergency.

CAUTION:

Never charge liquid into the low-pressure

side of system. Do not overcharge. During charging or

removal of refrigerant, be sure indoor-fan system is

operating.

IV. ADJUST REFRIGERANT CHARGE

NOTE:

The remaining start-up procedures and all refriger-

ant charge modifications should be done only under supervi-

sion of a qualified refrigeration mechanic.

With all fans operating, and compressor operating fully loaded,

adjust the refrigerant charge in accordance with the unit charg-

ing charts located on the inside of the control box doors and

in Fig. 12 and 13.

CAUTION:

Charge unit on cooling cycle only. If unit

is charged on heating cycle, overcharging may occur.

1. Be sure to use Refrigerant-22.

2. Regulate refrigerant drum valve to maintain suction pres-

sure at 80 psig while charging. Charge with vapor only,

at suction side of unit.

NOTE:

Do not depend on sight glass when charging unit. Use

charging chart.

Allow system to operate for 20 minutes. Take temperature

and pressure readings at liquid line service valve and check

values with the charging chart.

Plot point on charging chart. If point is above curve, add charge.

If point is below curve, reduce charge until point falls on line.

Record the final refrigerant charge.

If the sight glass is cloudy, check refrigerant charge again.

Ensure all fans are operating. Also ensure maximum allow-

able liquid lift has not been exceeded. If charged per chart

and if the sight glass is still cloudy, check for a plugged filter

drier or a partially closed solenoid valve. Replace or repair,

as needed.

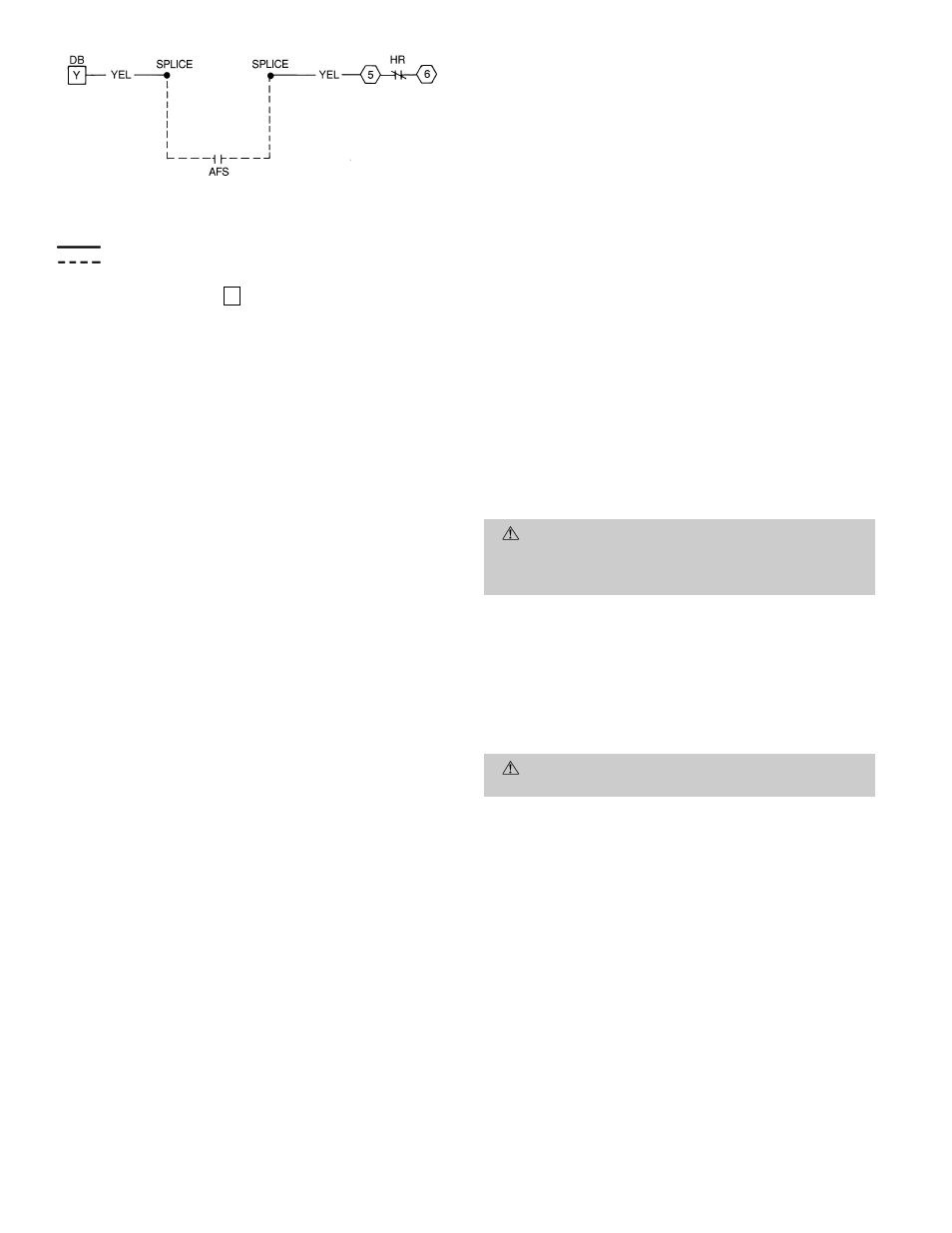

LEGEND

AFS — Airflow Switch (Sail Switch)

DB

— Defrost Board

HR

— Heat Relay

Factory Wiring

Field Wiring

NOTES:

Y

1. Locate YEL wire between

on DB and terminal 5 of HR and cut.

2. Splice airflow switch (AFS) (field supplied) contact wires (field pro-

vided) to two ends of cut YEL wire as depicted.

Fig. 11 — Field Wiring for Airflow Switch —

541A120,180/524A-H

—12—