Bryant 541A User Manual

Page 5

B. Refrigerant Line Design and Sizing

Consider the length of the piping required between the out-

door and indoor units. The maximum allowable line length is

100 ft. Select proper liquid and vapor line sizes from Table 4.

Contact your local representative if assistance is required for

design details and proper piping practices.

Table 4 — Piping Selection and Refrigerant

Charge Data

OUTDOOR

UNIT

541A

LENGTH 0F PIPING — FT*

MAXIMUM

LIQUID

LINE OD

(in.)

0-25

25-60

60-100†

Line Size (in. OD)

L

V

L

V

L

V

120

5

⁄

8

1

1

⁄

8

5

⁄

8

1

3

⁄

8

5

⁄

8

1

5

⁄

8

5

⁄

8

180

5

⁄

8

1

3

⁄

8

3

⁄

4

1

5

⁄

8

3

⁄

4

1

5

⁄

8

3

⁄

4

Approximate System Charge

lb**

Maximum

Charge —

lb

120

30

38

46

48

180

37

45

59

62

LEGEND

L — Liquid Line

V — Vapor Line

*Approximately 4 elbows assumed in determining pipe sizes.

†Maximum length of interconnecting piping is 100 ft.

**Approximate system charge is for estimating only. It includes charge

requirements for one outdoor unit, matching indoor coil, and intercon-

necting piping. See Preliminary Charge section on page 10.

NOTE: If there is a vertical separation between indoor and outdoor units,

see Table 3. Double vapor line riser may be required.

Carefully evaluate any vapor risers at minimum load condi-

tions to ensure proper compressor oil return. If the indoor

unit is above the outdoor unit, the riser will function as a hot

gas riser. If the outdoor unit is above the indoor unit, the riser

is a suction riser. Design and construct a double riser if nec-

essary. Contact your local representative if assistance is

required.

C. Liquid Line Piping Procedure

Pipe the system liquid line as follows:

WARNING:

Unit is pressurized with a holding charge

of refrigerant. Recover R-22 holding charge before re-

moving runaround liquid piping loop. Failure to re-

cover holding charge before removing piping loop could

result in equipment damage and severe injury.

1. Open service valves in sequence:

a. Discharge service valve on compressor.

b. Suction service valve on compressor.

c. Liquid line valve.

2. Remove

1

⁄

4

-in. flare cap from liquid valve Schrader port.

3. Attach refrigerant recovery device and recover holding

charge.

4. Remove runaround loop.

5. Connect system liquid line from liquid connection of out-

door (541A) unit to indoor unit liquid line connections.

See Fig. 5 for typical piping and wiring. Select proper

field-supplied bi-flow filter driers and install in the liq-

uid line. See Fig. 6. Install a field-supplied liquid mois-

ture indicator between the filter drier(s) and the liquid

connections on the indoor (524A-H) unit. Braze or silver

alloy solder all connections. Pass nitrogen or other inert

gas through piping while making connections to pre-

vent formation of copper oxide. (Copper oxides are ex-

tremely active under high temperature and pressure.

Failure to prevent collection of copper oxides may re-

sult in system component failures.)

D. Vapor Line Piping Procedure

Connect system vapor line to the vapor line stub on the out-

door unit and the vapor stubs on the indoor unit. At the in-

door unit, construct vapor piping branches as shown in Fig. 7

for good mixing of the refrigerant leaving the indoor coil dur-

ing cooling. This will ensure proper TXV (thermostatic ex-

pansion valve) bulb sensing.

Where vapor line is exposed to outdoor air, line must be in-

sulated. See Table 5 for insulation requirements.

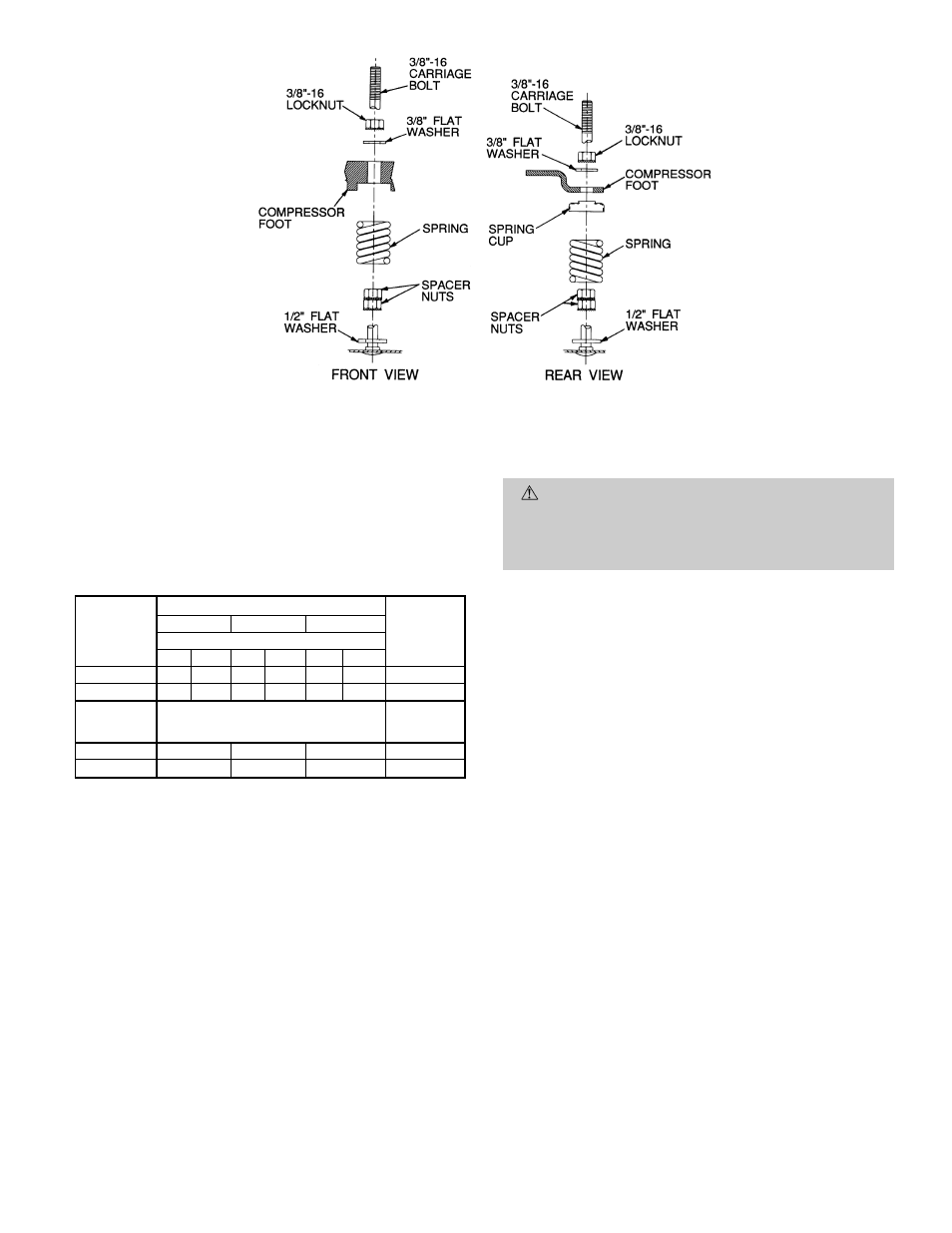

Fig. 4 — Compressor Mounting

—5—