Check for refrigerant leaks, Start--up adjustments – Bryant EVOLUTION 577D----A User Manual

Page 28

28

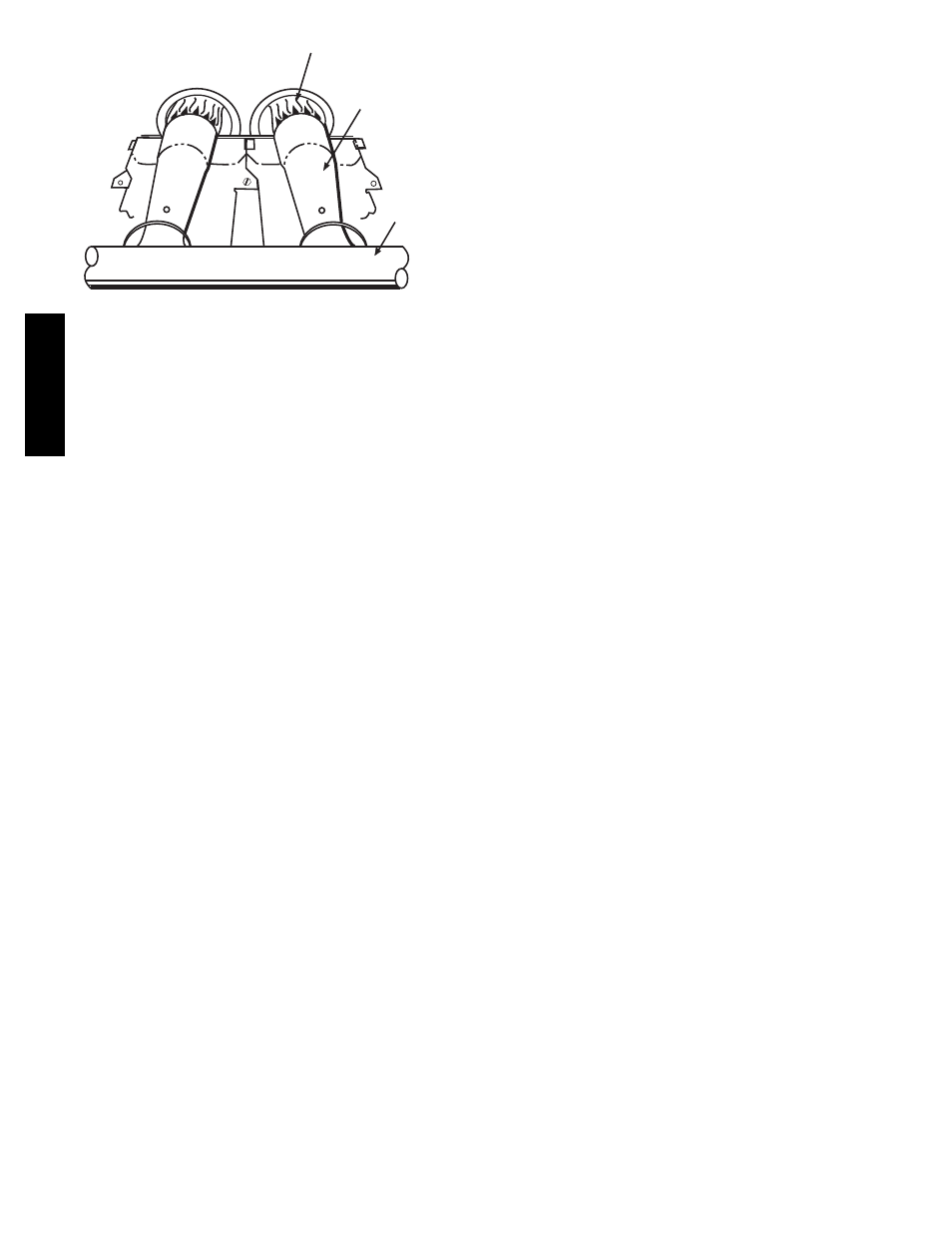

MANIFOLD

BURNER

BURNER FLAME

C99021

Fig. 21 -- Monoport Burner

LIMIT SWITCHES

Normally closed limit switch (LS) completes the control circuit.

Should the leaving--air temperature rise above the maximum

allowable temperature, the limit switch opens and the control

circuit “breaks.” Any interruption in the control circuit instantly

closes the gas valve and stops gas flow to the burners. The blower

motor continues to run until LS resets. The furnace board STATUS

LED will display STATUS CODE 33.

When the air temperature at the limit switch drops to the

low--temperature setting of the limit switch, the switch closes and

completes the control circuit. The direct--spark ignition system

cycles and the unit returns to normal heating operation.

ROLLOUT SWITCH

The function of the rollout switch is to close the main gas valve in

the event of flame rollout. The switch is located above the main

burners. When the temperature at the rollout switch reaches the

maximum allowable temperature, the control circuit trips, closing

the gas valve and stopping gas flow to the burners. The indoor fan

motor (IFM) continues to run until switch is reset. The furnace

board STATUS LED will display STATUS CODE 33.

CONTINUOUS FAN MODE

When continuous fan operation is requested by the UI indoor fan

motor will operate at continuous blower airflow. Continuous fan

operation is programmable. See the UI Owner’s Manual for

detailed instructions. Terminal EAC--1 is energized as long as the

indoor fan motor is energized.

During a call for gas heat, the Evolution control will transition the

indoor fan motor to continuous blower airflow or gas heat airflow,

whichever is lowest. The indoor fan motor will remain ON until

the burners ignite, then shut OFF and remain OFF for the

blower--ON delay allowing the heat exchangers to heat up more

quickly, then restarts at the end of the blower--ON delay period.

The indoor fan motor will revert to continuous--blower airflow

after the gas heating cycle is completed.

When the UI “calls for cooling”, the indoor fan motor will switch

to operate at cooling airflow. When the call for cooling is satisfied,

the indoor fan motor will operate an additional 90 seconds at

cooling airflow before transitioning back to continuous--blower

airflow.

When the call for continuous fan is removed, the indoor blower

will continue operating for an additional 5 seconds before shutting

down, if no other function requires blower motor operation.

COMPONENT TEST

The Evolution Furnace Board features a gas component test system

to help diagnose a system problem in the case of a gas component

failure. To initiate the component test procedure, ensure that there

are no UI inputs to the control (the ABCD connector can be

removed from the Evolution control board for this operation) and

all time delays have expired. Turn on setup switch SW1--6.

NOTE: The component test feature will not operate if the control

is receiving any UI signals or until all time delays have expired.

The component test sequence is as follows:

1. The control turns the inducer motor ON and keeps it ON

through step 3.

2. After waiting 10 seconds, the control turns the igniter ON

for 15 seconds, then OFF.

3. The control then turns the indoor fan motor on for 15

seconds, then OFF.

4. After shutting the blower motor OFF, the control runs the

inducer for 10 seconds, then turns it OFF.

NOTE:

The EAC terminals are energized when the blower is

operating.

After the component test is completed, one or more status codes

(11, 25, or 41) will flash. See component test section or Status

Code Label for explanation of status codes.

NOTE: To repeat component test, turn setup switch SW1--6 to

OFF and then back ON.

Check for Refrigerant Leaks

Locate and repair refrigerant leaks and charge the unit as follows:

1. Use both high-- and low--pressure ports to relieve system

pressure and reclaim remaining refrigerant.

2. Repair leak following accepted practices.

NOTE: Install a filter drier whenever the system has been opened

for repair.

3. Check system for leaks using an approved method.

4. Evacuate refrigerant system and reclaim refrigerant if no

additional leaks are found.

5. Charge unit with Puron (R--410A) refrigerant, using an

accurate scale. Refer to unit rating plate for required charge.

Start--Up Adjustments

Complete the required procedures given in the Pre--Start--Up

section before starting the unit. Do not jumper any safety devices

when operating the unit. Do not operate the unit in cooling mode

when the outdoor temperature is below 40°F (4°C) (unless

low--ambient operation is enabled in the UI). Do not rapid cycle

the compressor. Allow 5 min. between “on” cycles to prevent

compressor damage.

CHECKING

COOLING

AND

HEATING

CONTROL

OPERATION

See UI Installation Instructions for detailed system CHECKOUT.

CHECKING AND ADJUSTING REFRIGERANT CHARGE

The refrigerant system is fully charged with Puron (R--410A)

refrigerant and is tested and factory sealed.

NOTE: Any adjustment to refrigerant charge must be done with

unit operating in HIGH stage.

NOTE:

Adjustment of the refrigerant charge is not required

unless the unit is suspected of not having the proper R--410A

charge. The charging label and the tables shown refer to system

temperatures and pressures in cooling mode only. A refrigerant

charging label is attached to the outside of the unit.

577D

--

--

A