Warning – Bryant EVOLUTION 577D----A User Manual

Page 26

26

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

injury and/or death.

If the manifold pressure and/or gas rate is not properly

adjusted on HI and LO stages, excess carbon monoxide can

be produced.

!

WARNING

FIRE AND UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal

injury or death and/or property damage.

Unsafe operation of the unit may result if manifold pressure

is outside of the ranges listed in Table 6.

!

WARNING

Gas input rates on rating plate are for installations at altitudes up to

2000 ft (610 m). Input rate must be within ± 2% of rating plate

input.

1. Determine the correct gas input rate.

a. The rated gas inputs shown in Table 6 are for altitudes

from sea level to 2000 ft (610 m) above sea level.

These inputs are based on natural gas with a heating

value of 1025 Btu/ft3 at .60 specific gravity.

IN THE U.S.A.:

The input rating for altitudes above 2,000 ft (610 m) must be

reduced by 4 percent for each 1,000 ft (305 m) above sea level.

For installations below 2,000 ft, (610 m) refer to the unit rating

plate.

For installations above 2,000 ft, (610 m) multiply the input by on

the rating plate by the derate multiplier in Table 5 for the correct

input rate.

Table 5 – Altitude Derate Multiplier for U.S.A*.

Altitude ft (m)

Percent of Derate

Derate Multiplier

Factor{

0--2000

(0--610)

0

1.00

2001--3000*

(610--914)

8--12

0.90

3001--4000

(915--1219)

12--16

0.86

4001--5000

(1220--1524)

16--20

0.82

5001--6000

(1524--1829)

20--24

0.78

6001--7000

(1829--2134)

24--28

0.74

7001--8000

(2134--2438)

28--32

0.70

8001--9000

(2139--2743)

32--36

0.66

9001--10,000

(2744--3048)

36--40

0.62

* In Canada see Canadian Altitude Adjustment.

{

Derate multiplier factors are based on midpoint altitude for altitude range.

IN CANADA:

The input rating for altitudes from 2,000 (610 m) to 4,500 ft (1372

m) above sea level must be derated 10 percent by an authorized

Gas Conversion Station or Dealer.

EXAMPLE:

90,000 Btuh Input Furnace Installed at 4300 ft (1372 m).

Furnace Input Rate

Derate Multiplier

Furnace Input Rate

at Sea Level

X

Factor

=

at Installation

Altitude

90,000

X

0.90

=

81,000

b. When the gas supply being used has a different heating

value or specific gravity, refer to national and local

codes, or contact your distributor to determine the

required orifice size.

2. Adjust manifold pressure to obtain low stage input rate (See

Fig. 19).

a. Turn off gas supply to unit.

b. Remove pipe plug on manifold (See Fig. 20 and

connect manometer). Turn on gas supply to unit.

c. Turn gas valve switch to ON.

d. Set unit to run for 20 minutes in low--stage gas heat

operation using the ”INSTALLER CHECKOUT” menu

on the User Interface.

e. Remove regulator adjustment cap from low stage gas

valve pressure regulator (See Fig. 19) and turn

low--stage adjusting screw (3/16 or smaller flat--tipped

screwdriver) counterclockwise (out) to decrease rate and

clockwise (in) to increase input rate.

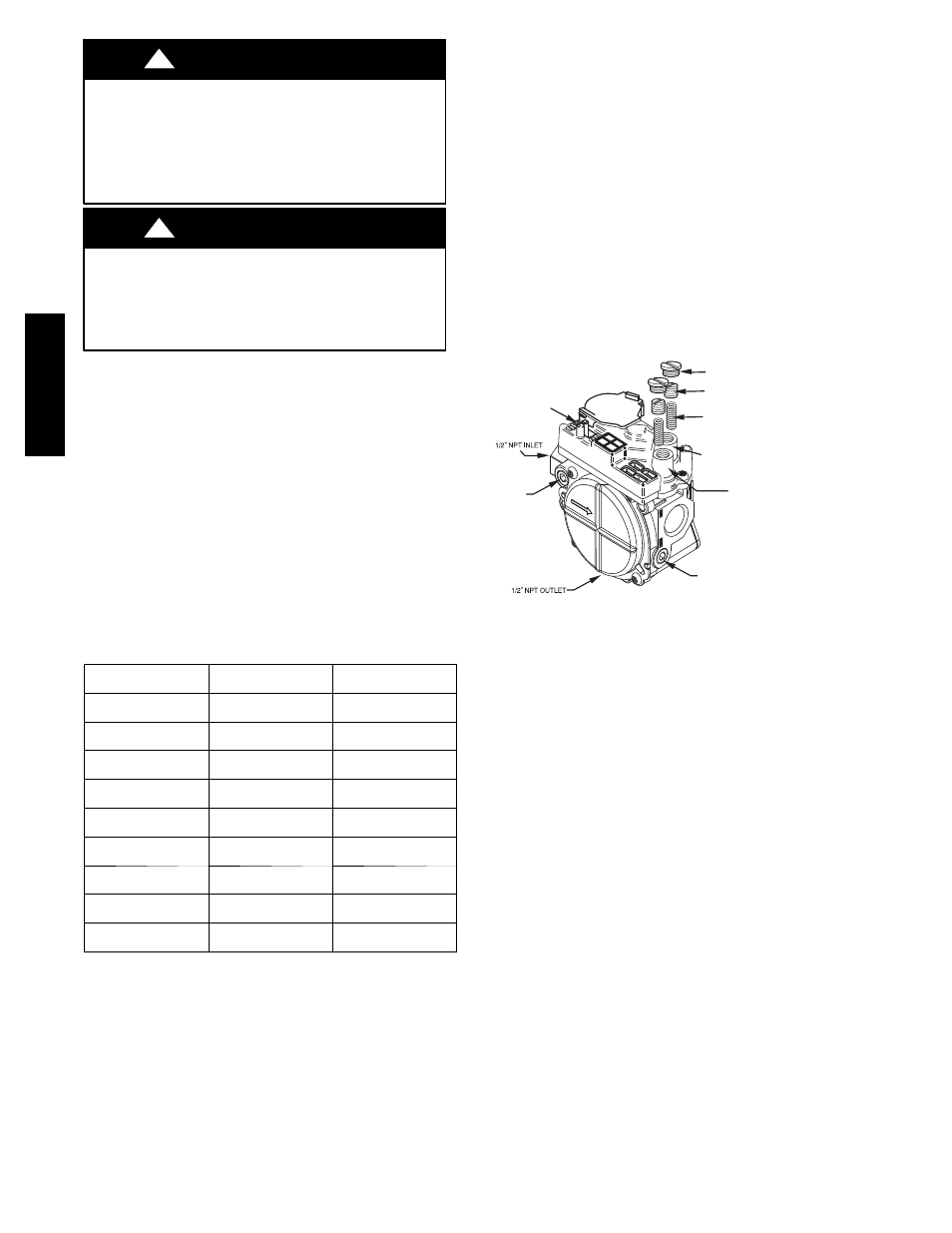

REGULATOR COVER SCREW

PLASTIC ADJUST SCREW

LOW STAGE

GAS PRESSURE

REGULATOR ADJUSTMENT

MANIFOLD

PRESSURE TAP

INLET

PRESSURE TAP

ON/OFF SWITCH

REGULATOR SPRING

HIGH STAGE GAS

PRESSURE REGULATOR

ADJUSTMENT

A04167

Fig. 19 -- Redundant Automatic Gas Control Valve

NOTE: DO NOT set low stage manifold pressure less than 1.4

IN. W.C. or more than 2.0 IN. W.C. for natural gas. If manifold

pressure is outside this range, change main burner orifices.

f. Re--install low stage regulator adjustment cap.

g. Leave manometer connected.

NOTE: If orifice hole appears damaged or it is suspected to have

been re--drilled, check orifice hole with a numbered drill bit of the

correct size. Never re--drill an orifice. A burr--free and squarely

aligned orifice hole is essential for proper flame characteristics.

3. Verify natural gas low stage input rate.

a. Turn off all other gas appliances and pilots served by

the gas meter.

b. If unit is not running, set unit to run for 20 minutes in

low--stage gas heat operation using the ”INSTALLER

CHECKOUT” menu on the UI.

c. Record number of seconds for gas meter to complete

one revolution.

d. Divide number of seconds in step c. into 3600 (number

of seconds in 1 hour).

e. Multiply result of step d. by the number of cubic feet

shown for one revolution of test dial to obtain cubic feet

of gas flow per hour.

f. Multiply result of step f. by Btu heating value of the gas

to obtain total measured input shown in Table 6.

(Consult the local gas supplier if the heating value of

gas is not known).

EXAMPLE: Assume a 90,000 high stage input unit is being

installed. Assume that the size of the dial is 2 cubic ft., one

revolution takes 129 sec., and the heating value of the gas is 1025

Btu/ft

3

. Proceed as follows:

577D

--

--

A