Xerox iGen4 Digital Press con Xerox EX Print Server Powered by Fiery-16493 User Manual

Page 7

6 of 20

Revision Dec 2007

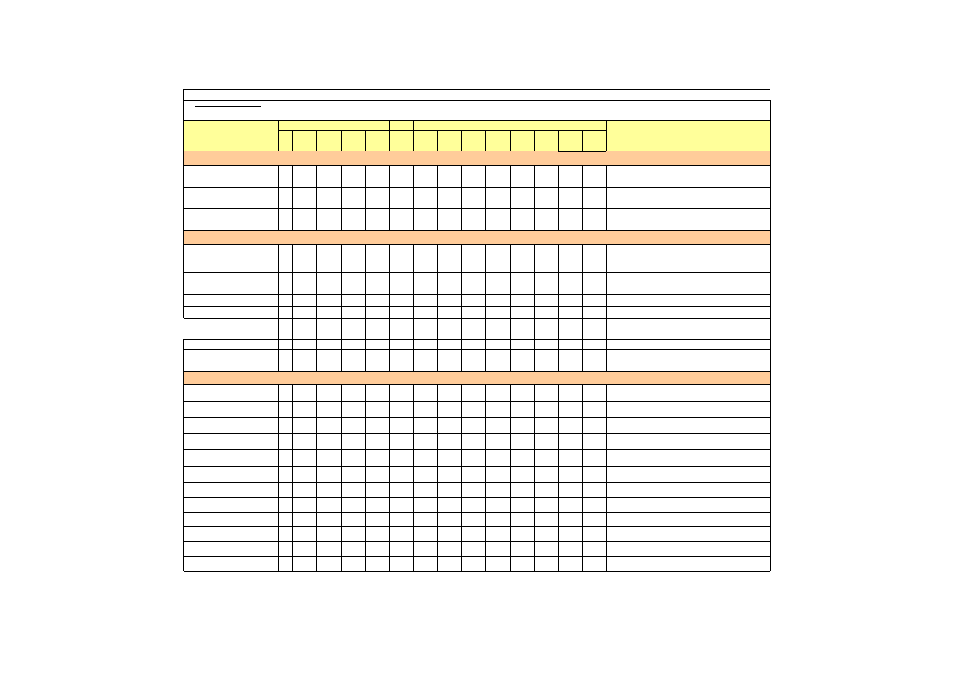

Grammage

Weight (gsm)

A4

A3

SRA3

Other Size

Stock Library Name (Full Media Name)

It is imperative to utilize the bolded, abbreviated stock name for

easy migration to future enhancements to the stock library and

media management tools.

Standard cut sizes

Drilled

Best Practices for Operation

Weight of the

paper in grams

per square

meter

Sides Coated

Coating Type

Type

Sequence

Color

Thickness

(microns)

Cleanup

Finish

The Xerox Guaranteed Media List contains Xerox paper and specialty media that has been extensively tested on the Xerox iGen3 90/100/110 Digital Production Press for image quality and performance. All Xerox paper and specialty media on this list are digitally

optimized, designed and manufactured for optimal performance in Xerox digital printing equipment. Our extensive testing and stringent specifications ensure that we are able to guarantee the performance and consistency of Xerox paper and specialty media.

Xerox paper and specialty media are tested and qualified by Xerox laboratories to guarantee consistent quality.

Xerox iGen3 90/100/110 Digital Production Press Europe Guaranteed Media List Jan 2008

Specialties- Synthetic Films

XeroxPremiumNeverTear95

(Xerox Premium NeverTear 95 micron)

No

003R98056

003R98057

003R98031

003R98032

125

Coated Two

Sides

Gloss

Plain

0

White

95

Yes

Smooth

Static build up may affect media runnability and/or stacking.

XeroxPremiumNeverTear120

(Xerox Premium Never Tear 120 micron)

No

003R98058

003R98059

003R98035

003R98036

155

Coated Two

Sides

Gloss

Plain

0

White

120

Yes

Smooth

Static build up may affect media runnability and/or stacking.

XeroxDuraPaper X250

(Xerox DuraPapaer X250)

003R97513

200

Uncoated

N/A

Plain

0

White

255

No

Regular

If image permanence adjustment is required, refer to ADJ 1-Pressure Roll Contact Arc Adjustment procedure i

the latest Customer Maintenance Manual.

Specialties- Other

Xerox UltraMagnet

(Xerox Ultra Magnet)

003R98060

350

Coated One

Side

Gloss

Plain

White

194

No

Smooth

Simplex only recommended

It is recommended that this media be run to stacker top tray.

Static build up may affect media runnability and/or stacking.

Feed from a lower tray only.

To enable running toggle NVM 12509 (Lower Tray Multifeed Detected FLTByp).

To enable running Service must set NVM 6876 (LE Late tat TAR sensor Jam Offset) to maximum value.

Output to top tray or bypass tray, if enabled

XeroxTransferPaper

(Xerox One Step Transfer Paper)

003R97949

003R97951

118

Coated One

Side

Gloss

Custom

0

White

143

No

Smooth

Simplex only recommended

Static build up may affect media runnability and/or stacking.

XeroxLasWinGraphiX C

(Xerox Laser Window GraphiX Clear)

003R97494

003R98675

003R98676

003R98677

200

Coated One

Side

Gloss

Transparency

Clear

114

No

Smooth

For uniform image quality, do not image within 3 mm of die cut on back of decal.

Simplex only recommended

Static build up may affect media runnability and/or stacking

XeroxLasWinGraphiX O

(Xerox Laser Window GraphiX Opaque)

003R97511

003R97539

003R98678

003R98679

200

Coated One

Side

Gloss

Transparency

Clear

114

No

Smooth

For uniform image quality, do not image within 3 mm of die cut on back of decal.

Simplex only recommended

Static build up may affect media runnability and/or stacking

003R98199

200

Coated One

Side

Gloss

Transparency

Clear

187

No

Smooth

This media may have a mottled appearance due to paper formation (image density and glos

Stack quality and stack height may be affected due to media structure or high area coverage.

Simplex only recommended

Static build up may affect media runnability and/or stacking.

Deliver to stacker FACE DOWN to avoid stacking issues

XeroxTransWh 150 gsm

(Xerox Translucent White 150 gsm)

007R96576

150

Coated Two

Sides

Matte

Plain

White

160

No

Smooth

XeroxDocuPac M

(Xerox DocuPac Folders Matte)

003R97353

180

Coated Two

Sides

Matte

Custom

0

White

223

No

Smooth

For uniform image quality, do not image within 10 mm of raised score or 2 mm of dimpled score

Specialties- Carbonless

XeroxCarb2SWP

(Xerox Carbonless, 2 part, Straight PreCollated, White and

Pink)

003R99107

80

Uncoated

N/A

Ordered

2

White

110

Yes

Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended

XeroxCarb2SWY

(Xerox Carbonless, 2 part, Straight PreCollated, White and

Yellow)

003R99105

80

Uncoated

N/A

Ordered

2

White

110

Yes

Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended

XeroxCarb3RPYW

(Xerox Carbonless, 3 part, Reverse PreCollated, Pink, Yelllow

and White)

003R99109

80

Uncoated

N/A

Ordered

3

White

110

No

Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended

XeroxCarb3SWYP

(Xerox Carbonless, 3 Part, Straight PreCollated, White, Yellow

and Pink)

003R99108

80

Uncoated

N/A

Ordered

3

White

110

No

Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended

XeroxCarb4RGPYW

(Xerox Carbonless, 4 part, Reverse PreCollated, Green, Pink,

Yellow and White)

003R99112

80

Uncoated

N/A

Ordered

4

White

110

No

Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended

XeroxCarb4SWYPB

(Xerox Carbonless, 4 part, Straight PreCollated, White,

Yellow,Pink and Blue)

003R99111

80

Uncoated

N/A

Ordered

4

White

110

No

Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

Reverse PreCollated product run face up to stacker is recommended

XeroxCarbCBSingleW

(Xerox Carbonless, Coated Back, Singles, White)

003R99069

80

Uncoated

N/A

Plain

White

110

No

Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

XeroxCarbCFBSingleW

(Xerox Carbonless, Coated Front and Back, Singles, White)

003R99070

80

Uncoated

N/A

Plain

White

110

No

Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

XeroxCarbCFBSingleY

(Xerox Carbonless, Coated Front and Back, Singles , Yellow)

003R99071

80

Uncoated

N/A

Plain

Yellow

112

No

Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

XeroxCarbCFSingleP

(Xerox Carbonless, Coated Front, Single, Pink)

003R99077

80

Uncoated

N/A

Plain

Pink

107

No

Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

XeroxCarbCFSingleW

(Xerox Carbonless, Coated Front, Singles, White)

003R99075

80

Uncoated

N/A

Plain

White

110

No

Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

XeroxCarbCFsingleY

(Xerox Carbonless, Coated Front, Singles, Yellow)

003R99076

80

Uncoated

N/A

Plain

Yellow

112

No

Regular

This media may have a mottled appearance due to paper formation (image density and gloss).

Optimization of decurler settings may be needed for best stacking and runnability.

Fuser Fluid II is recommended for duplex applications.

- iGen4 Digital Press con Xerox FreeFlow Print Server and DocuSP-16494 iGen3 Digital Production Press con Xerox FreeFlow Print Server and DocuSP-16476 iGen3 Digital Production Press con Xerox EX Print Server Powered by Fiery-16475 iGen4 Digital Press con Xerox CX Print Server Powered by Creo-16489 iGen3 Digital Production Press con Xerox CX Print Server Powered by Creo-16474 iGen3 Digital Production Press avec Xerox CX Print Server Powered by Creo-13393 iGen4 Digital Press avec Xerox EX Print Server Powered by Fiery-13412 iGen4 Digital Press avec Xerox FreeFlow Print Server and DocuSP-13413 iGen4 Digital Press avec Xerox CX Print Server Powered by Creo-13408 iGen3 Digital Production Press avec Xerox EX Print Server Powered by Fiery-13394 iGen3 Digital Production Press avec Xerox FreeFlow Print Server and DocuSP-13395 iGen4 Digital Press mit Xerox FreeFlow Print Server and DocuSP-10865 iGen4 Digital Press mit Xerox EX Print Server Powered by Fiery-10864 iGen3 Digital Production Press mit Xerox CX Print Server Powered by Creo-10845 iGen3 Digital Production Press mit Xerox EX Print Server Powered by Fiery-10846 iGen4 Digital Press mit Xerox CX Print Server Powered by Creo-10860 iGen3 Digital Production Press mit Xerox FreeFlow Print Server and DocuSP-10847 iGen4 Digital Press con Xerox EX Print Server Powered by Fiery-18996 iGen3 Digital Production Press con Xerox EX Print Server Powered by Fiery-18978 iGen4 Digital Press con Xerox FreeFlow Print Server and DocuSP-18997 iGen3 Digital Production Press con Xerox FreeFlow Print Server and DocuSP-18979 iGen3 Digital Production Press con Xerox CX Print Server Powered by Creo-18977 iGen4 Digital Press con Xerox CX Print Server Powered by Creo-18992