Installation & maintenance instructions, Pilot operated regulator – Norgren R24P Series User Manual

Page 2

R24

Installation & Maintenance

Instructions

WARNING

These products are intended for use in industrial

compressed air systems only. Do not use these products

where pressures and temperatures can exceed those listed

under Technical Data.

If outlet pressure in excess of the regulator pressure

setting could cause downstream equipment to rupture or

malfunction, install a pressure relief device downstream of

the regulator. The relief pressure and flow capacity of the

relief device must satisfy system requirements.

The accuracy of the indication of pressure gauges can

change, both during shipment (despite care in packaging)

and during the service life. If a pressure gauge is to be

used with these products and if inaccurate indications may

be hazardous to personnel or property, the gauge should be

calibrated before initial installation and at regular intervals

during use.

Before using these products with fluids other than air,

for non industrial applications, or for life-support systems

consult Norgren.

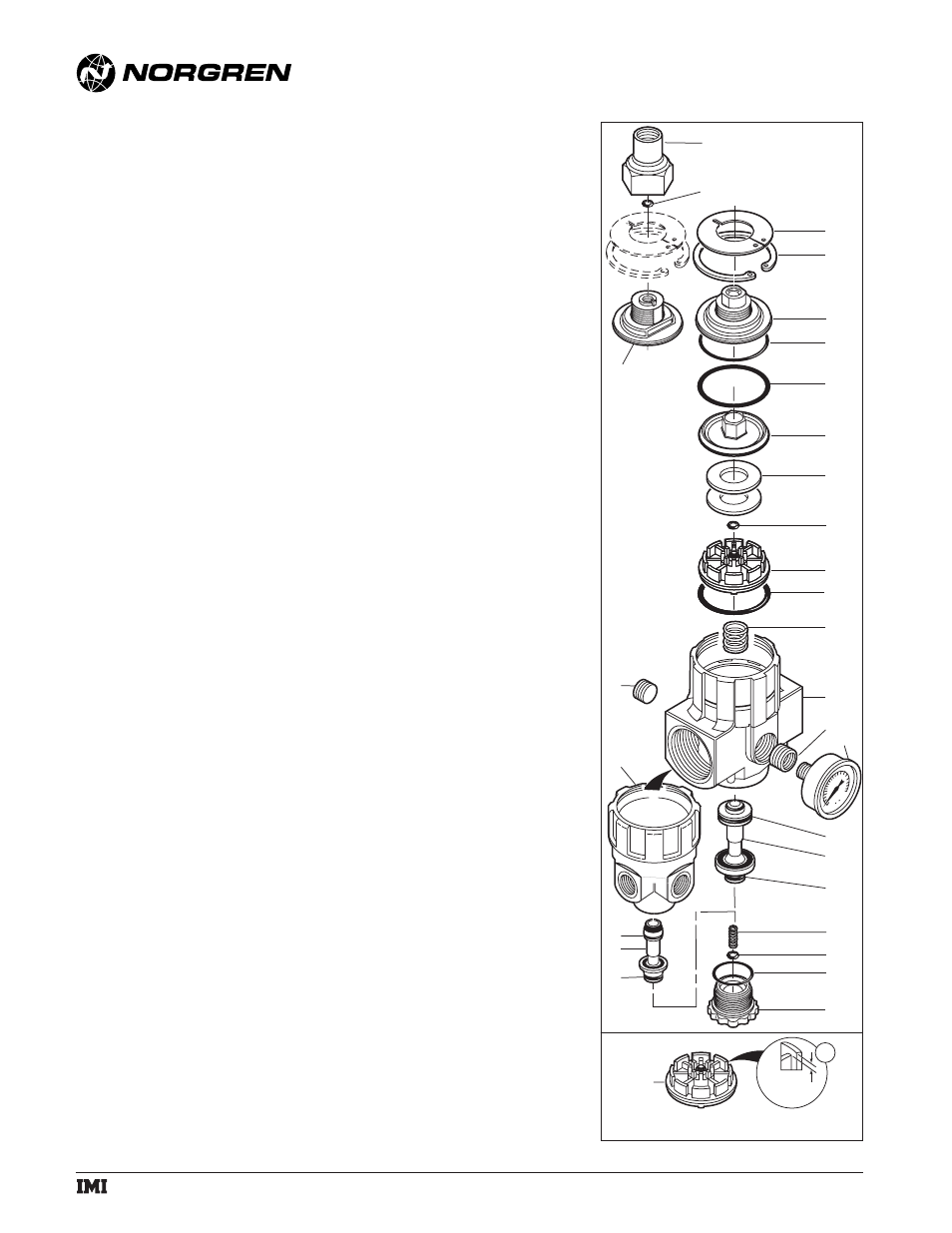

DISASSEMBLY

1. Regulator can be disassembled without removal from air

line.

2. Shut off inlet pressure to pilot regulator and to the R24.

Reduce pressure in inlet and outlet lines to zero.

3. Turn pilot regulator adjustment counterclockwise to

remove all force on regulating spring.

4. Disassemble in general accordance with the item numbers

on exploded view. On early models, unscrew adapter (1),

then remove o-ring (2). Current models do not use these

items.

WARNING

Prior to performing step 5, make certain air

pressure upstream and downstream of the R24

is at zero psi.

5. Use retaining ring pliers to remove the top plate (3) and

retaining ring (4). Pull cap (5 or 6) and o-ring (7) from

body.

6. Pull upper and lower piston assemblies (8 thru 13) from

body. Remove spring (14).

7. Unscrew bottom plug (15) to gain access to the parts (16

thru 23) located in the lower portion of the body.

CLEANING

1. Clean parts with warm water and soap.

2. Rinse and dry parts. Blow out internal passages in body

(24, 25) with clean, dry compressed air.

3. Inspect parts. Replace those found to be damaged.

ASSEMBLY

1. Lubricate o-rings and surfaces in contact with o-rings with

a light coat of good quality o-ring grease.

2. Place spring (14) in position in the body, then place the

upper and lower piston assembly (8 thru 13 *) in the

body. Place o-ring (7) in position on the cap (5 or 6) then

place cap in body.

3. Use retaining ring pliers to install retaining ring (4) and

top plate (3).

WARNING

Make sure retaining ring (4) is fully seated in the

groove in body.

4. On early models, install o-ring (2) and air pilot adapter (1).

5. Install lower section parts (16 thru 23) in body.

6. Torque Table

Item

Torque Inch-Pounds (Nm)

1 (adapter)

50 to 75 (5.6 to 8.5)

12 (Bottom plug)

20 to 30 (2.3 to 3.4)

* Two washers (10) are used on current R24 regulators.

Three washers were used on early R24 regulators

manufactured from September, 1993 to March, 1994. The

design of the piston (11) was changed in early 1994, and

one washer was eliminated. The washer support ribs on

the early pistons (Detail A of exploded view) are recessed

approximately 0.188" (5mm). The support ribs on current

pistons are recessed approximately 0.063" (2mm) . Use

only 2 washers (10) when replacing the early piston with a

current piston.

1

5

2

3

4

6

7

9

8

10

27

24

26

14

23

22

20

21

17

15

28

18

19

11

13

11

A

0.188"

(5mm)

25

16

19

12

a subsidiary of IMI plc

IM-414.240.02

(2/02)

Pilot Operated Regulator

© Norgren 2002