Norgren L22 Series Datasheets User Manual

Norgren Hardware

See Section ALE-24 for Accessories

Littleton, CO USA

Phone 303-794-2611

www.norgren.com

L22

●

Metallic parts meet NACE Standard MR-01-75*

●

Low flow start point

●

Built-in flow sensor gives almost constant oil/air ratio

over a wide range of flows

●

Can be filled under pressure

●

Simple and accurate drip rate adjustment

●

Ideal for general lubrication applications

●

Meets certain requirements of Military

Specifications**

* National Association of Corrosion Engineers (NACE) MR-01-75 defines requirements for

sulphide stress cracking resistant materials used in well-head and other corrosive environments.

** Meets certain requirements of MIL-S-901C (Navy) 15 Jan 1963: Military Specifications Shock

Test H.I. (High Impact); Shipboard Machinery, Equipment and Systems and MIL-STD-167-1

(Ships) Military Standard Mechanical Vibrations of Shipboard Equipment.

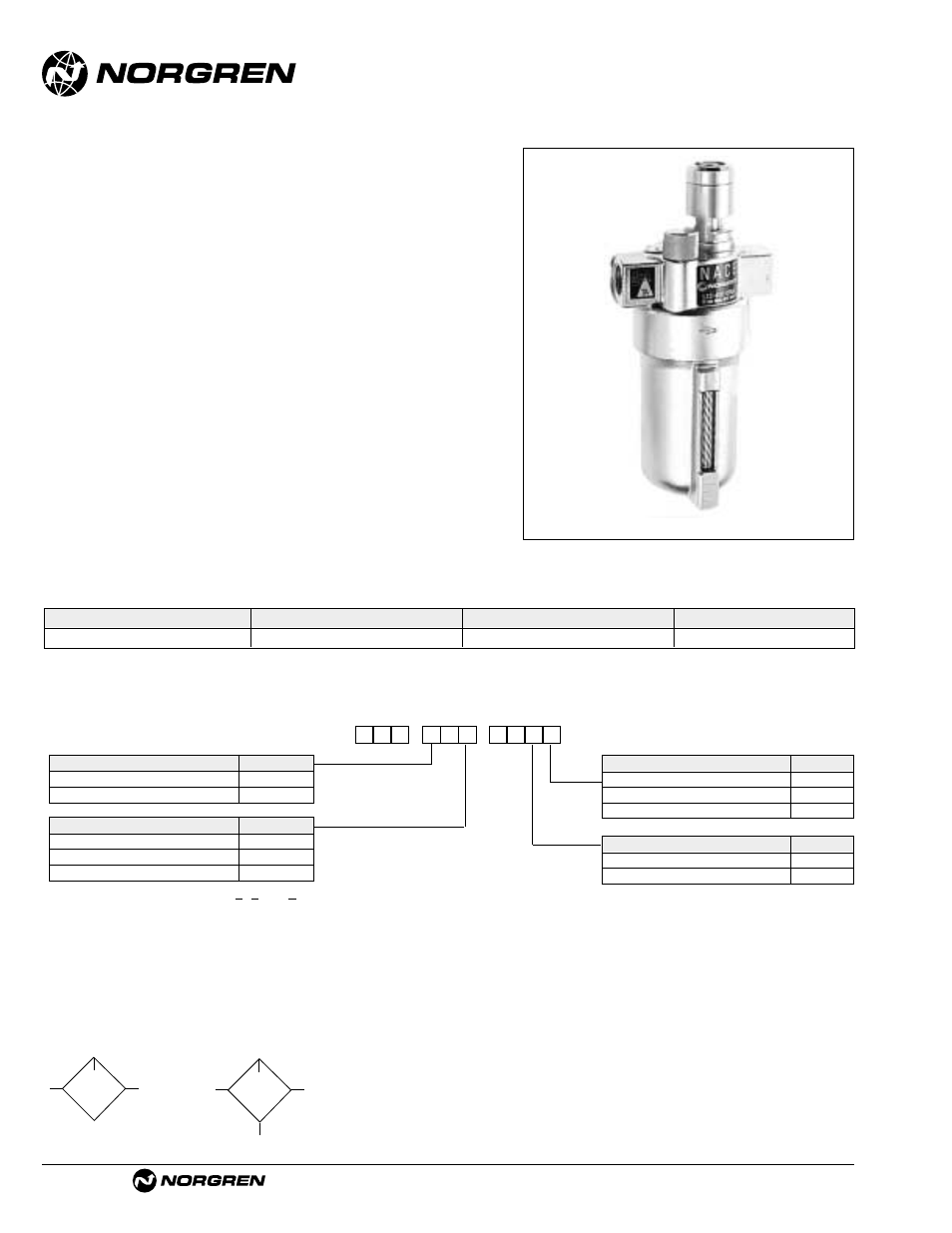

L22 Stainless Steel Oil-Fog Lubricator

1/2 PTF

ALE-16-14

2

2

L

★

0

★

O P

★ ★

-

-

Alternative Models

Port Size

Substitute

1/2"

4

Special

6**

Modification

Substitute

Closed bowl

0

Plugged closed bowl

5

Special

7*

Thread

Substitute

PTF

A

ISO G

D

Special

S*

Bowl

Substitute

Closed bowl

8

Manual drain

D

** 3/4" body (3/4 x 16 UNF) L22-6X7-OPXS

Type

Model Number

Flow

†

scfm (dm

3

/s)

Weight lbs (kg)

Oil-Fog

L22-405-OP8A

102 scfm (48 dm

3

/s)

4.29 (1.93)

Ordering Information.

Models listed are oil-fog units with closed bowl (no drain) and PTF threads.

ISO Symbols

No Drain

With Drain

†Typical flow with 90 psig (6.3 bar) inlet pressure and 7 psig (0.5 bar) pressure drop.