Ids industrial dispenser instructions, Red' jumper dispense control – FMI IDS User Manual

Page 3

IDS INDUSTRIAL DISPENSER

INSTRUCTIONS

3

1

1.0 Description

The IDS Industrial Dispenser has a stepper motor and a self-contained step motor controller specifically

designed for use with Fluid Metering valveless pumps. It contains its own step output drivers and can be

set to several run modes utilizing either internal or external controls. This system is designed for maxi-

mum performance in all industrial situations. If you have any questions at all, please don't hesitate to call

our technical hot line at 1-800-223-3388.

1.1 Features

• Pre-set Run Modes.

• Multiple Control Methods: PLC *, Relay, 0-5 VDC, or manually by internal switches.

• Dispense Run, Purge, etc.

• Variable speeds.

• Verification of dispense cycle and rotation.

• Opto-isolated inputs.

• Auto-Current reduction, when not in a running mode.

• Internally fused at 2.5 A via a plug-in fuse socket.

• Automatic over temperature shutdown of drive current output if driver devices reach 70 º C internal

temper atures. Note: This does not prevent motor overheating!

• Rugged 304 Stainless Steel, NEMA type 12, IP 65 enclosure.

• Forward/Reverse Function Default SW 12 Open is clockwise direction

*Typical compatible PLC's are: Texas instruments Ti 305, SIMATIC, GE Fanuc OCS stations, Crouzet

Type RPX and DIAL 5, DIAL 10 systems, IDEC's series of Micro 3 or Micro 3 C and PLC Direct DL105

through DL 405. PLCs require opto-isolated or relay outputs for start, run or dispense functions and an

opto-isolated current loop input.

2.0 Run Modes

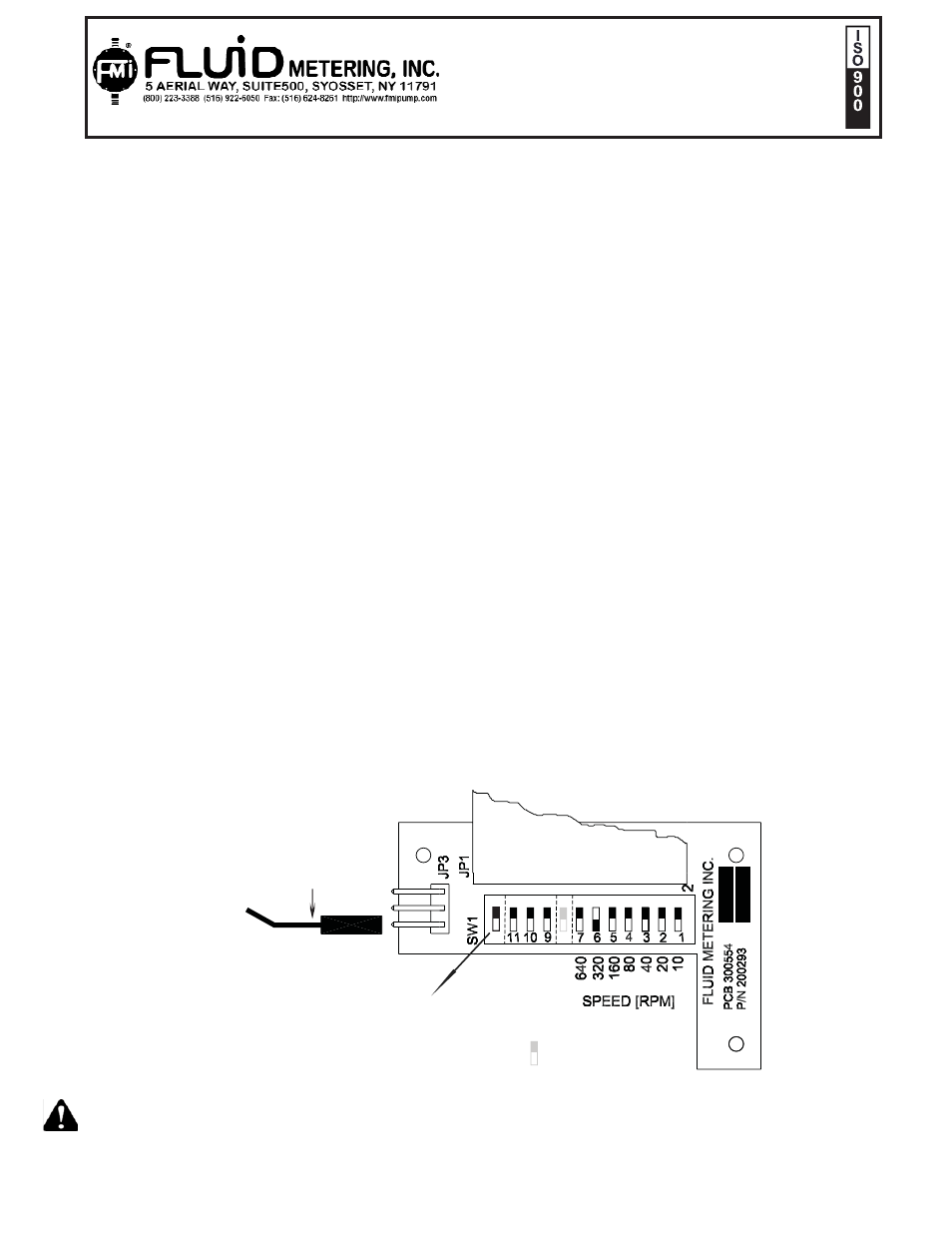

The step motor controller board housed in the IDS can drive pumps in any of the following modes by

changing switches on the Switchboard 200293 as shown below.

OPEN

1

2

4

12

8

11

10

9

'RED' Jumper

Dispense control

switchboard #200293

Dispense

Switches

OFF

OFF

*

*#8 Always off

FWD/REV

ENCLOSURE FASTENERS MUST BE TORQUED TO 6 INCH POUNDS ± 10% TO ASSURE PROPER SEALING.