FMI SPD User Manual

Instructions, Models gpd, spd, Pneumatic drives

INSTRUCTIONS

MODELS GPD, SPD

PNEUMATIC DRIVES

FMI Pneumatic Pump Drives are similar in design to the standard FMI “Q” pump; please review the Q431

Instruction and Parts Identification Sheet.

OPERATION:

1.

Follow all safety codes during installation of your FMI Pneumatic Drive.

2.

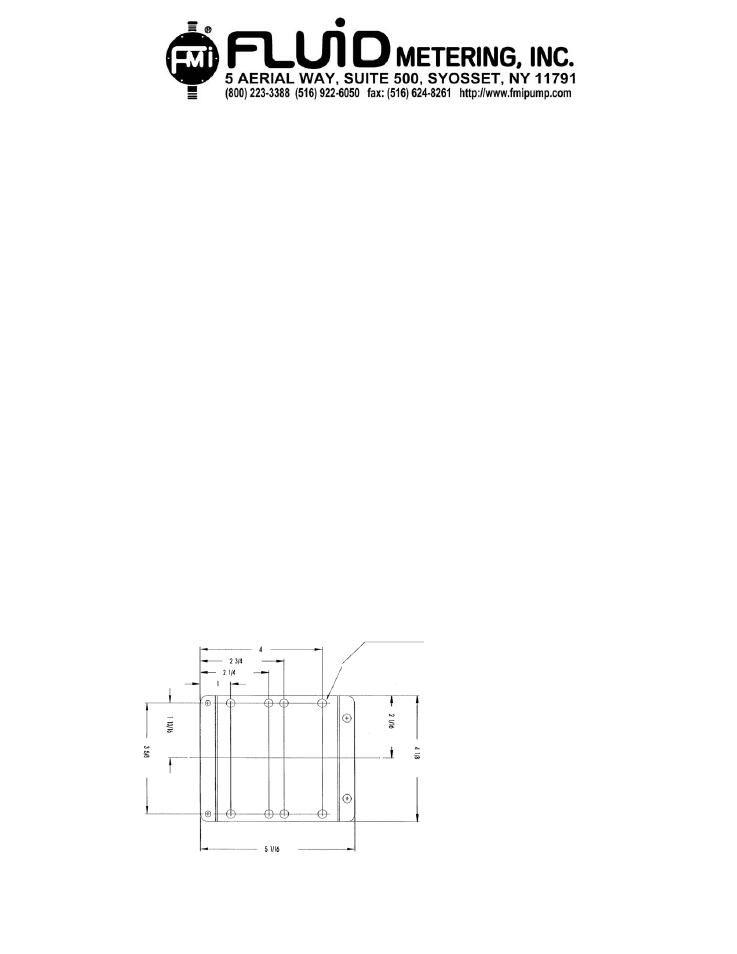

Your Standard Pneumatic Drive Pump (SPD) or Gear Pneumatic Drive (GPD) must be rigidly

mounted using the four 9/32 Dia. holes in bracket Q648, see fig. 1. (Drives can be mounted

either horizontally on table or lab bench, or vertically on wall with pump head facing down).

3.

Important. For proper rotation (clockwise) air must enter right port (use 1/8” NPT). All air

Lines should be clean and free of foreign matter. Install standard filter, regulator and

lubricator as close as possible to motor inlet port. The lubricant should feed oil at a rate of

one drop for every 50-75 CFM of air going through motor.

4.

Air Requirement: SPD 9-10 CFM at 40 psi GPD 14-16 CFM at 40 psi. If reduced noise is

desired exhaust air can be run to some remote location away from work area using flexible

tubing, all lines should have minimal amount of bends, elbows, tees, etc.

5. Pump flow rates may be varied by simply regulating air flow to the motor. A typical speed

regulation system is composed of two pressure regulators, one on inlet line, and one on

outlet line.

MAINTENANCE:

1.

Lubrication of Standard Pneumatic Drive: use detergent SAE #10 automotive engine oil.

2.

Lubrication of Gear Pneumatic Drive: use a 300 SUS @ 100º F turbine quality lubricant. For

horizontal operation remove the two hole plugs, (see exploded view GPD on reverse side). Add

oil to one hole until second hole overflows. For vertical operation fill to overflow point of upper-

most

hole.

9/32 DIA. MOUNTING

HOLES (4 PLACES)

Fig. 1

IN PD431-03

PRINTED IN U.S.A.