Chemglass 75L thru 100L Jacketed User Manual

Page 9

www.cglifesciences.com

Complete Assembly Instructions

The jacketed process reactor, the fully assembled reactor head, stirrer shaft & agitators, PTFE stirrer bearing,

temperature probe & adapter, high flow manifold blocks, and safety shields are shipped assembled on the support frame.

All joints must be properly greased to avoid “freezing”and improve vacuum. PTFE sleeves and keck clips are available

separately.

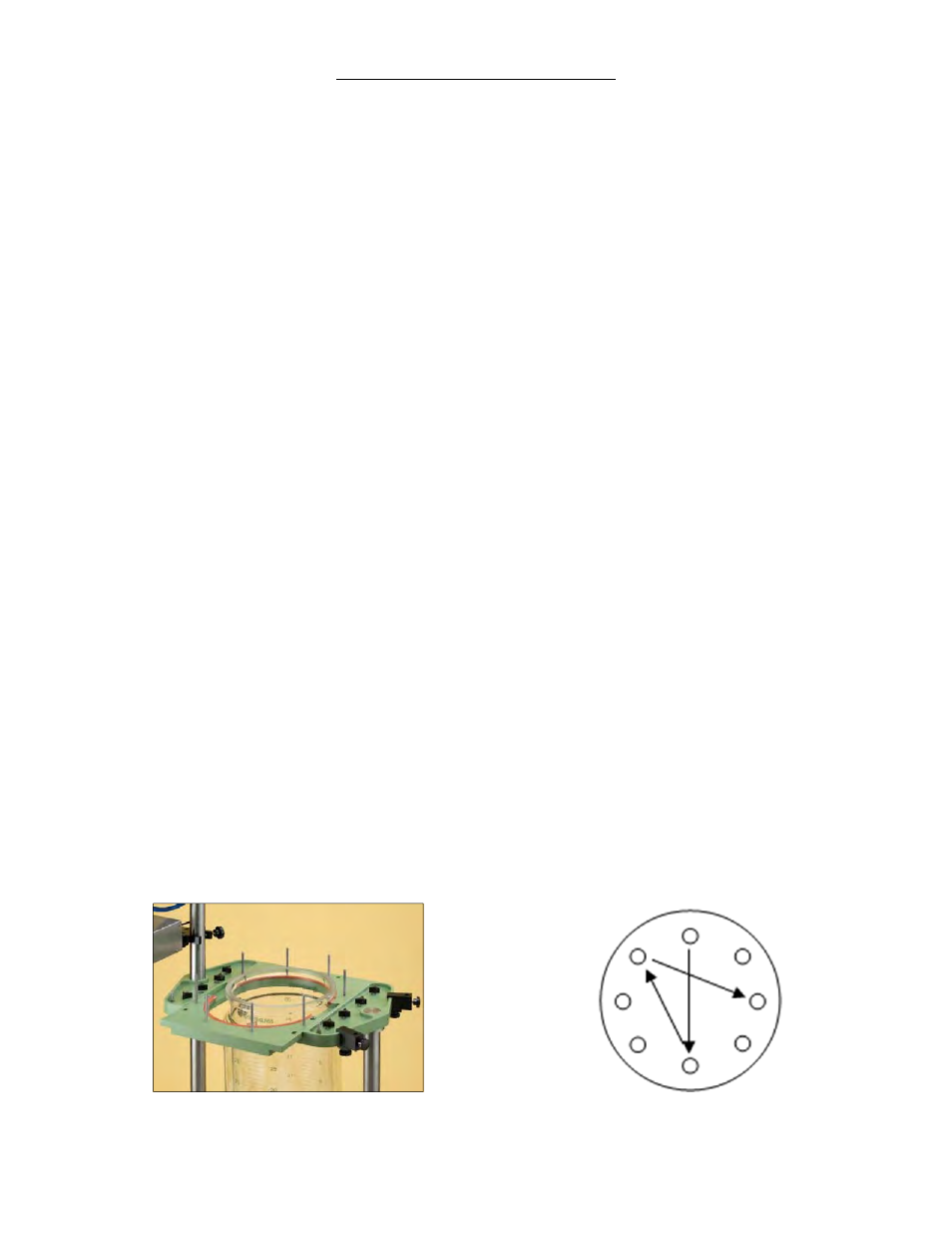

1. Carefully lower the reaction vessel into the support frame and rest the bottom of flange on the red silicone tubing.

Slide front reaction vessel plate tight against the reactor and tighten the plate via the four Allen screws (Figure A).

2. Attach the zero dead space drain valve to reaction vessel via 2”beaded pipe coupling. Tighten coupling to specified

torque setting.

3. Attach the high flow manifold system to support frame, as described above, and then attach the S.S. beaded pipe end

of hose to inlet/outlet of reaction vessel.

4. Place the PTFE envelope gasket on the flange of the reaction vessel.

5. Assemble the stirrer shaft and agitators, and lower into the reaction vessel.

6. While lowering the reaction vessel lid onto the vessel, carefully insert the end of the stirrer shaft through the center

neck of the lid. PLEASE NOTE: THE PTFE STIRRER BEARING IS NOT INSERTED AT THIS TIME.

7. Slide the PTFE stirrer bearing over the end of the stirrer shaft and “press”into the center neck, sealing the o-ring.

8. Position the powder fill port towards the front of the reactor.

9. Secure the vessel and lid together with the clamp ring, making sure the entire PTFE envelope gasket is seated

evenly on the flange. Tighten the wing nuts in a star-like pattern (Figure B). Work your way around the entire clamp

until you have repeated this 3-4 times and all the wing nuts are tight. DO NOT OVER TIGHTEN.

10. Attach the 1/4 HP electric stirrer motor to the upper universal motor mount arm via four socket head cap screws.

Screws are shipped installed on the motor.

11. Attach the universal stirrer shaft coupling to the electric stirrer motor shaft.

12. Insert the end of the stirrer shaft into the coupling and tighten the collar with an Allen wrench. Check the vertical

alignment of the reactor and adjust if necessary.

13. Tighten the black compression nut on the PTFE stirrer bearing, which compresses the bearing onto the stirring

shaft.

14. Attach the electric stirrer motor controller and the digital temperature monitor to the support frame via the large

Kwik Klamp II and 1/2" OD 90°support rod.

15. Attach the control cord from the electric stirrer motor to the rear panel of the controller. Make sure the speed

control knob on the controller is turned completely off BEFORE turning the controller on. If using the air motor,

attach the air source to the motor. The brass needle valve on the back of the air motor should be CLOSED.

16. Insert thermocouple through the thermocouple adapter and then insert the adapter into the desired side neck. Adjust

the depth of the thermocouple by tightening the Chem-Thread at the top of the adapter. PLEASE NOTE: CHECK

TO SEE THAT THE THERMOCOUPLE DOES NOT COME INTO CONTACT WITH ANY OF THE

AGITATORS BY MANUALLY TURNING THE STIRRER SHAFT. Attach the thermocouple cord to the probe

and then to the temperature monitor.

17. Attach condensers and any other peripheral glassware.

Figure A Figure B