Operation – Mittler Bros Machine & Tool 400-VSUADJ User Manual

Page 7

- 7 -

OPERATION

WEAR SAFETY GLASSES

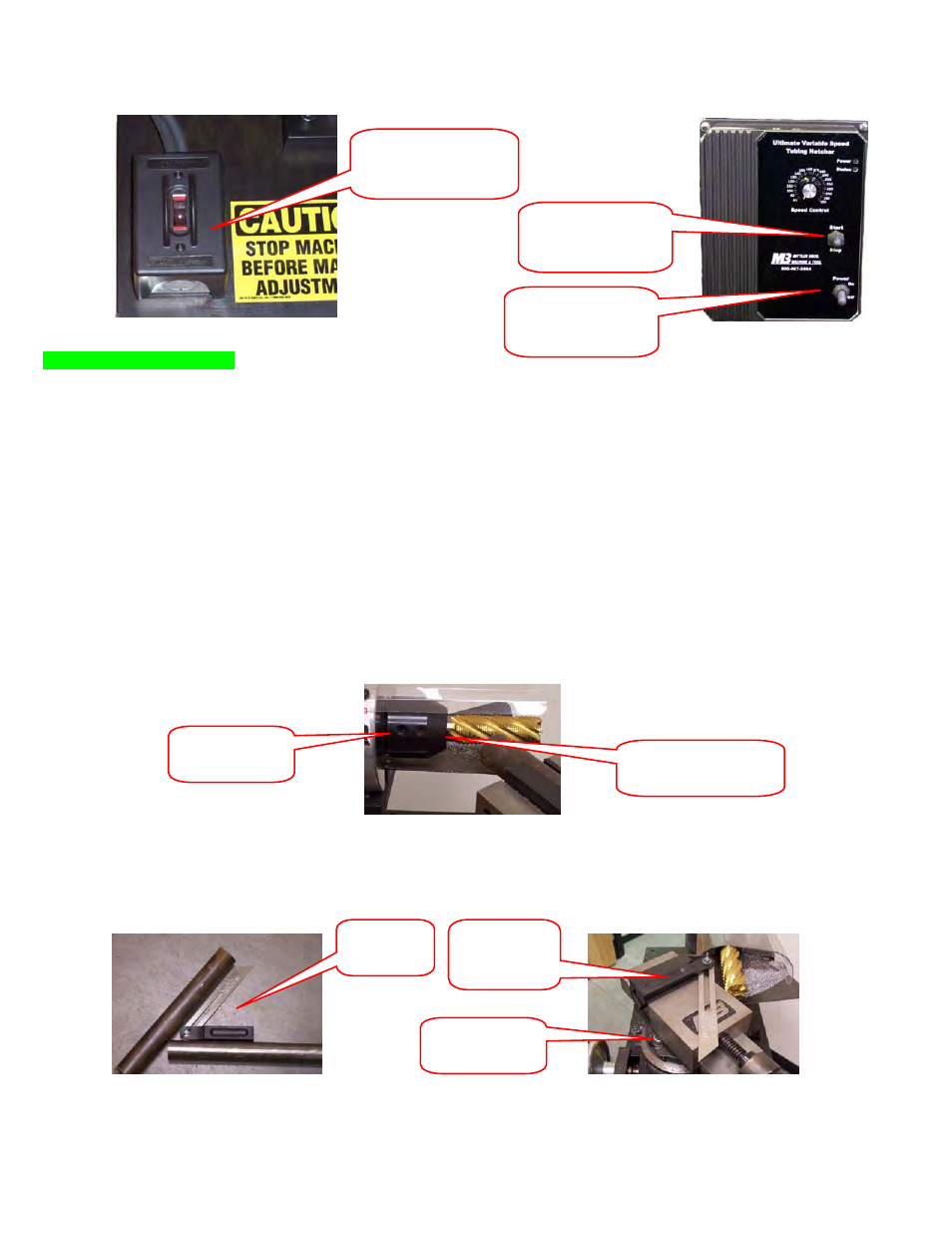

1. Be sure your machine is turned off and is plugged into the proper power source.

[Both the

Single Speed & Variable Speed machine operate on 110 Volt single (1) phase electric. Switch is on the left

side of the main base plate for single speed and on the control box as shown above.

Variable Speed: Use the MASTER on / off switch at bottom right of control box to turn ON the machine for the day or off at

the end of the day, or off for maintenance only.

Use the

RUN / STOP switch at the center right for normal on / off between notches.

Pull Up & HOLD the

RUN / STOP switch for a few seconds to start cutter rotating.

NOTE: Repeated use of the master switch for regular On/Off use can cause damage to the control unit.

2. Install a cutter into the spindle to match the size of tubing you are notching. If the

cutter is 1-1/8” OD or smaller the appropriate reducer bushing is required, see page

23. Align the flat surfaces on the cutter shank with the setscrews and Tighten the two

set screws with the supplied “T” handle wrench.

3. Calculate the angle of the notch. A sliding “T” Bevel, as shown, is one way of doing

this. If you already know the notch angle go to

step #5.

4. Set the vise to the correct angle required. Use the supplied ¾” Combination Wrench to

loosen the two vise swivel locknuts. Rotate the vise to the desired angle and lock

down by tightening the two lock nuts.

#1, Standard

Machine

ON / OFF

Switch

#1, Variable

Speed Machine

MASTER Switch

#1, Variable

Speed Machine

Run/Stop Switch

#2, Tighten

Set Screws

#2, Install Reducer

Bushing if needed

#3, Set to

Angle

#4, Tighten

Lock Nuts

#4, Match

Vise to

Angle