General maintanance, Gib adjustments, Left to right slide assembly – Mittler Bros Machine & Tool 400-VSUADJ User Manual

Page 11

- 11 -

GENERAL MAINTANANCE

SAFETY FIRST / BE SURE MACHINE IS UNPLUGGED BEFORE ANY MAINTAINCE IS PERFORMED

1. Lubrication is required at the grease fittings on the feed table 3 times per year. Use any

general purpose grease as required for smooth operation.

2. Keep as clean as possible at all times for long life. Be sure the Cooling slots for the motor

fan are kept clean as well as the cooling louvers on the Variable speed control box.

3. The Gear Box and spindle assembly come pre-lubed from the factory and need no further

attention. If you see grease or oil coming from either area please contact the factory for

service information.

GIB ADJUSTMENTS

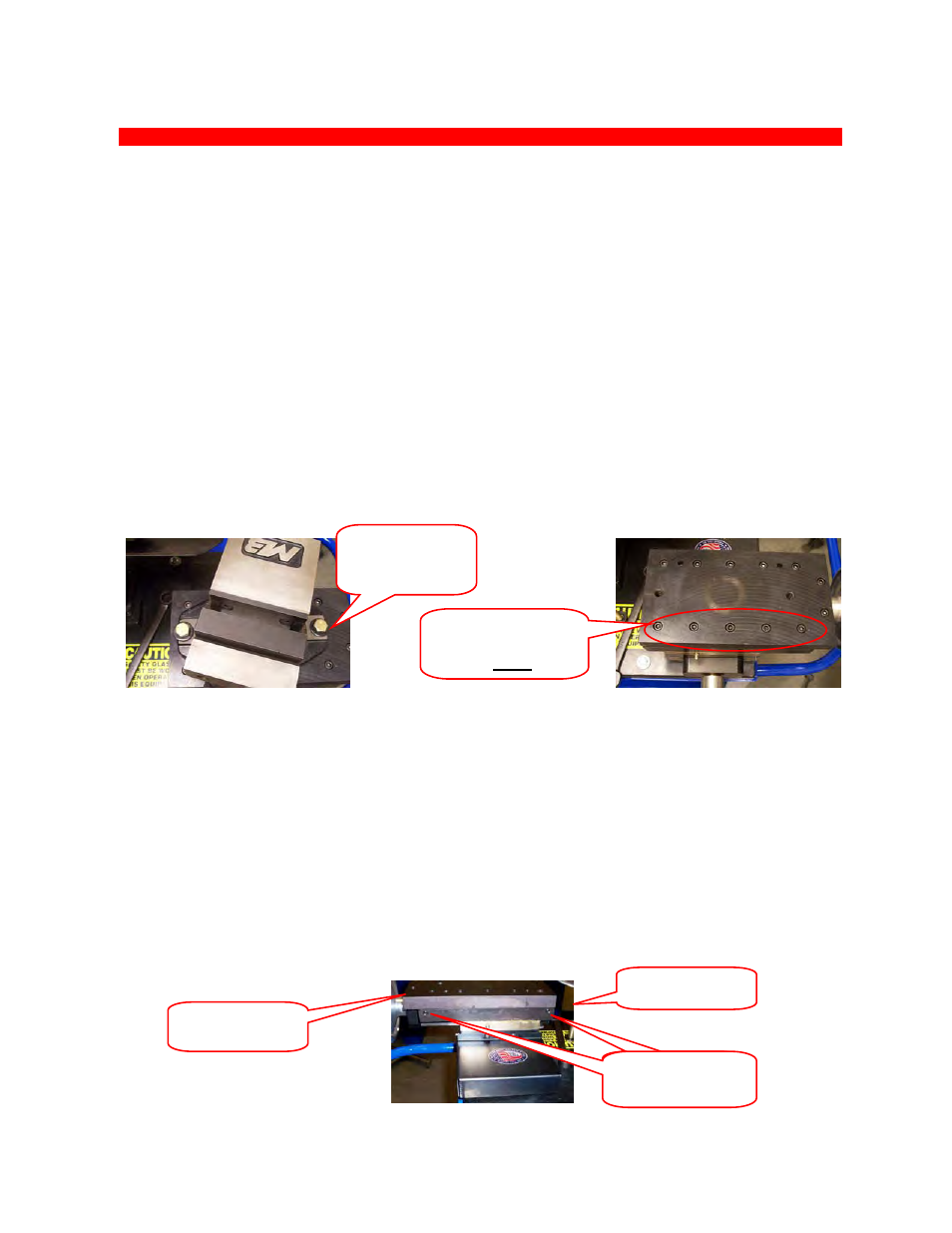

Left to Right Slide Assembly

1. Clean machine of all chips.

2. Remove the vise assembly from the slide assembly by removing the two swivel base

mounting bolts.

3. Loosen the five gib mounting bolts, on the operator side of the vise mounting plate.

Snug these bolts back up but

DO NOT TIGHTEN.

4. Turn clockwise each Gib adjusting screw, on the back side of the vise mounting plate, this

will “spread & tighten” the gibs.

Make very small adjustments at a time!

After making an

adjustment turn the hand wheel and run through the entire range of travel feeling for

smooth and snug movement. If it seems too tight, back the adjusting screws off a very

small amount and then use a soft head hammer and tap the gib opposite the adjusting

screws and repeat the process.

#2, Remove

Swivel Base

Bolts

#3, Loosen Gib

Mounting Bolts

Then

Snug Up

#4, Motor side

#4, Motor side

#4, Gib Adjusting

Screws

#4, Vise

Mounting Plate