Mittler Bros Machine & Tool 400-VSUADJ User Manual

Page 12

- 12 -

5. Once you are satisfied with the adjustments tighten the five gib mounting bolts and recheck

your adjustments. This procedure may take a few tries. You can now remount the vise to

the mounting plate.

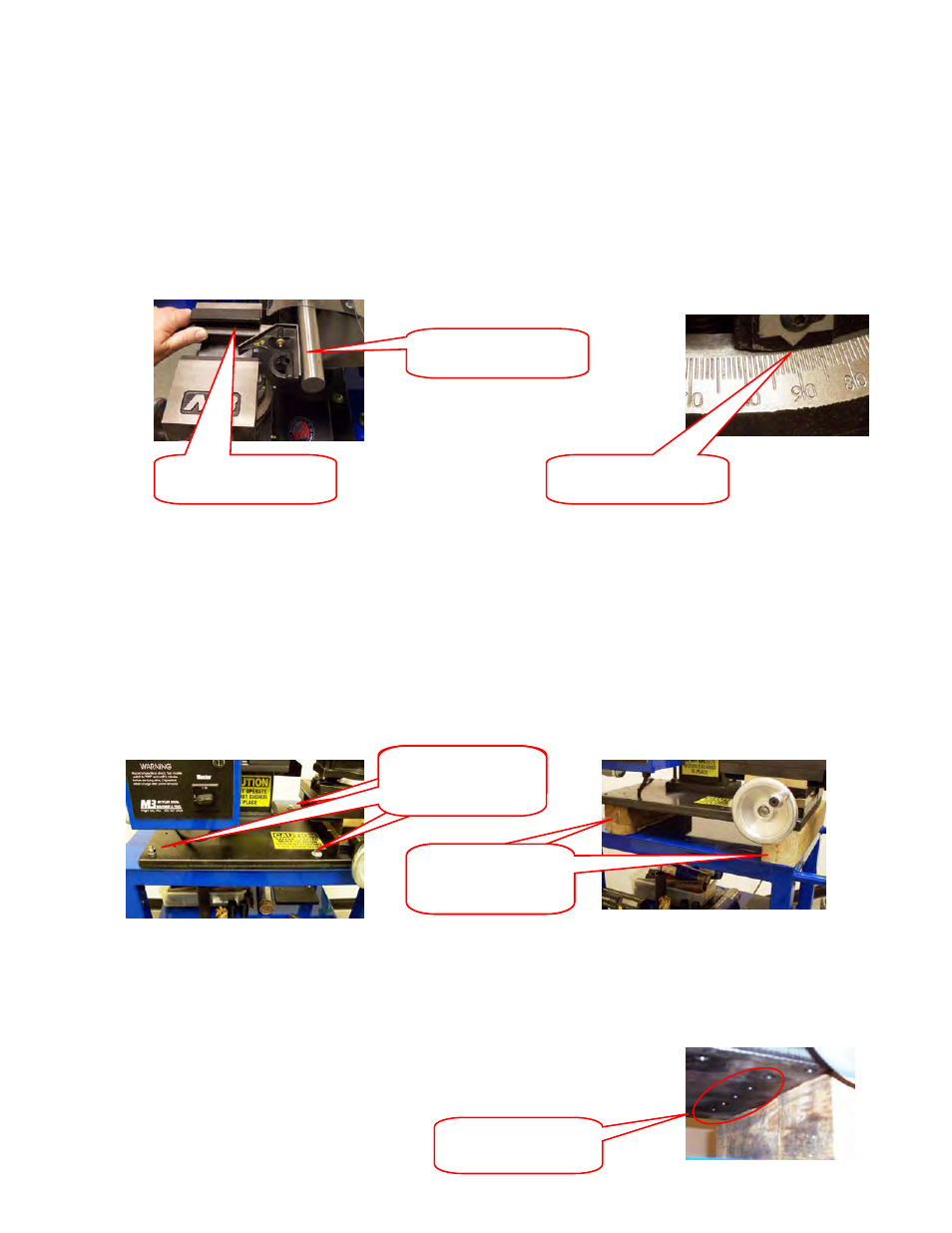

6. You will need to realign the vise to be square with the cutter. Insert a piece of 1-1/4” OD

tubing or shaft into the spindle and lightly tighten the set screws. Hold a combination

square or machinist square tight in the groove of the V jaw as shown. Loosen the adjusting

jam nuts and rotate the vise until the square and the tube / shaft in the spindle are at 90° to

each other. Use a wrench and tighten the adjusting jam nuts. Check the degree pointer. If it

does not read 90° you will need to loosen the screw and set it back to 90°.

7. If the hand wheels feel loose or tight you will need to adjust the Nylock nut in the center of

each hand wheel to set the tension.

8. If you have any questions please call 1-800-467-2464 for technical support.

In & Out Slide Assembly

1. Clean machine of all chips.

2. Remove the 4 mounting bolts that hold the unit to the stand or bench.

3. Raise the machine as shown on Page 4 Step #5 and place a 4x4 block under each end.

Be sure that the 4x4 block on the vise end is even with the edge of the base plate as

shown above. Use a C clamp at each end to secure the machine to your work table.

4. Loosen the five gib mounting bolts, on the bottom of the plate,

shown at right. Snug these bolts back up but

DO NOT

TIGHTEN.

#6, Square in Bottom

of V Jaw

#6, Square & Shaft

at 90° to Each Other.

#6, Re-adjust Pointer

to 90°

#2, Remove Base

Mounting Bolts

#3, Place 4 x 4’s

Under Ends of

Base Plate

#2, Remove Base

Mounting Bolts

#2, Remove 4

Base Mounting

Bolts

#3, Place 4 x 4’s

Under Ends of

Base Plate.

#4, 5 Gib Mounting

Bolts