Two sided machine in/out gib adjustment – Mittler Bros Machine & Tool 400-VSUADJ User Manual

Page 13

- 13 -

5. Turn clockwise each Gib adjusting screw, on the back side of the vise mounting plate, this

will “spread & tighten” the gibs.

Make very small adjustments at a time!

After making an

adjustment turn the hand wheel and run through the entire range of travel feeling for

smooth and snug movement. If it seems too tight, back the adjusting screws off a very

small amount and then use a soft head hammer and tap the gib opposite the adjusting

screws and repeat the process.

6. Once you are satisfied with the adjustments tighten the five gib mounting bolts and recheck

your adjustments. This procedure may take a few tries.

7. Remove the C clamps and position the lift slings as shown on Page 4 Step #5. Lift the

machine and remove the 4x4 blocks. Set the machine down on your stand / table and bolt

down using the previously removed bolts.

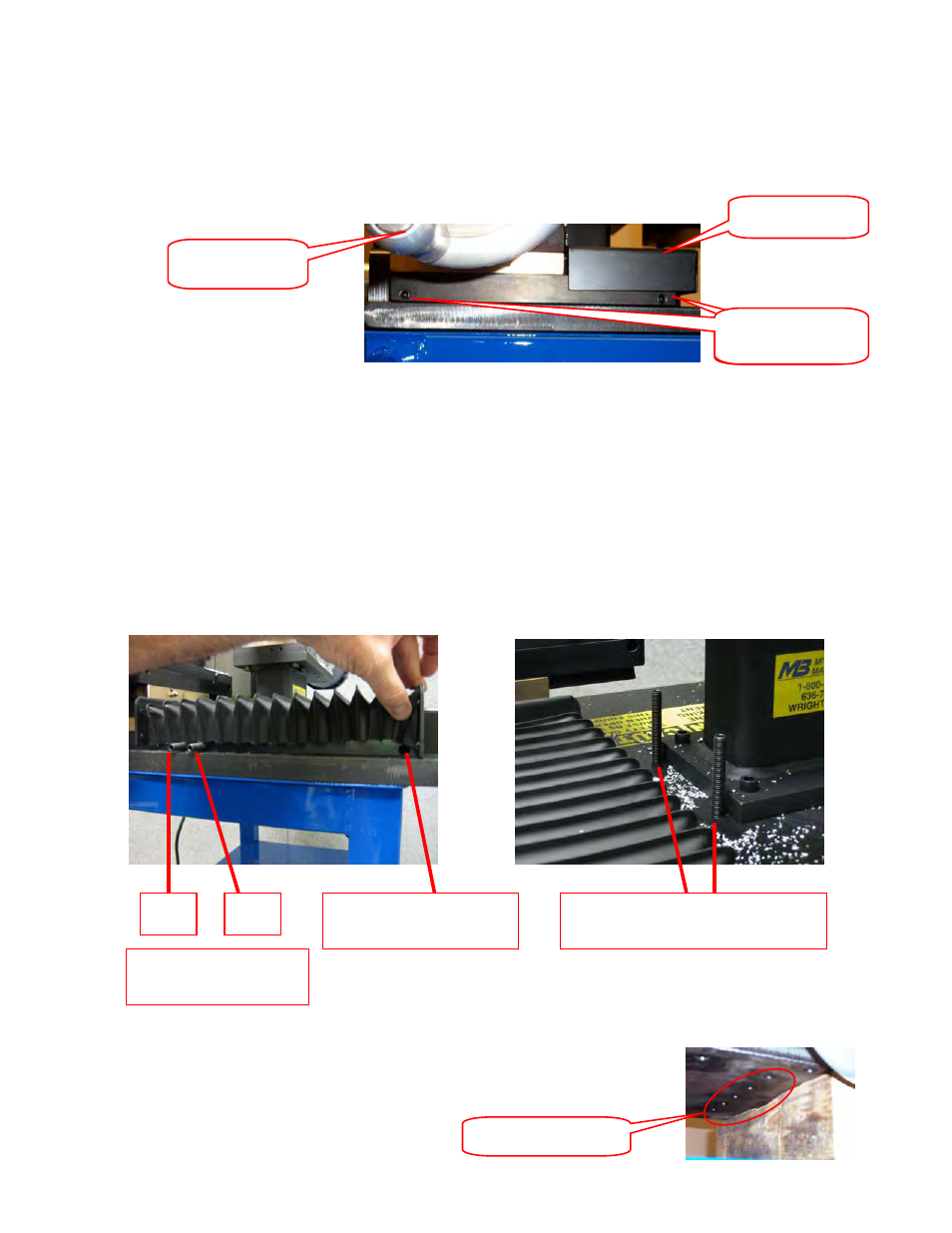

TWO SIDED MACHINE IN/OUT GIB ADJUSTMENT

#

1. Follow Steps 1 through 3 on Page 9.

2. Loosen ten (10) gib mounting bolts, on the base plate bottom.

Snug these bolts back up but

DO NOT TIGHTEN.

Chip Guard

#4, Motor side

#5, Gib Adjusting

Screws

#5, Left / Right

Crank Handle

Centered In/Out Gib

Adjustment Screws

Back Side In/Out Gib

Adjustment Screw

Storage Location for Centered

In/Out Gib Adjustment Screws

Gib Mounting Bolts

#1

#2