Pump priming – Goulds Pumps 3796 i-FRAME - IOM User Manual

Page 61

NOTICE:

Make sure to lubricate the packing. Failure to do so may result in shortening the life of the packing and the

pump.

You must use an external sealing liquid under these conditions:

• The pumped fluid includes abrasive particles.

• The stuffing-box pressure is below atmospheric pressure when the pump is running with a suction lift

or when the suction source is in a vacuum. Under these conditions, packing is not cooled and

lubricated and air is drawn into pump.

Conditions for application of an external liquid

If...

Then...

The stuffing box pressure is above atmospheric

pressure and the pumped fluid is clean.

Normal gland leaks of 40 to 60 drops per minute is

usually sufficient to lubricate and cool the packing.

You do not need sealing liquid.

The stuffing box pressure is below atmospheric

pressure or the pumped fluid is not clean.

An outside source of clean compatible liquid is

required.

An outside source of clean compatible liquid is

required.

You must connect the piping to the lantern ring

connection with a 40 to 60 drops-per-minute leak

rate. The pressure must be 15 psi (1.01 kg/cm

2

)

above the stuffing box pressure.

Pump priming

Pump priming with the suction supply below the pump (3796)

Model 3796 is self-priming and does not require a foot valve in the suction line or manual priming prior to

startup (except for the initial charge). However, in a pressurized system, the pump requires an air vent or a

permanent bypass line in the discharge piping to vent the evacuated air.

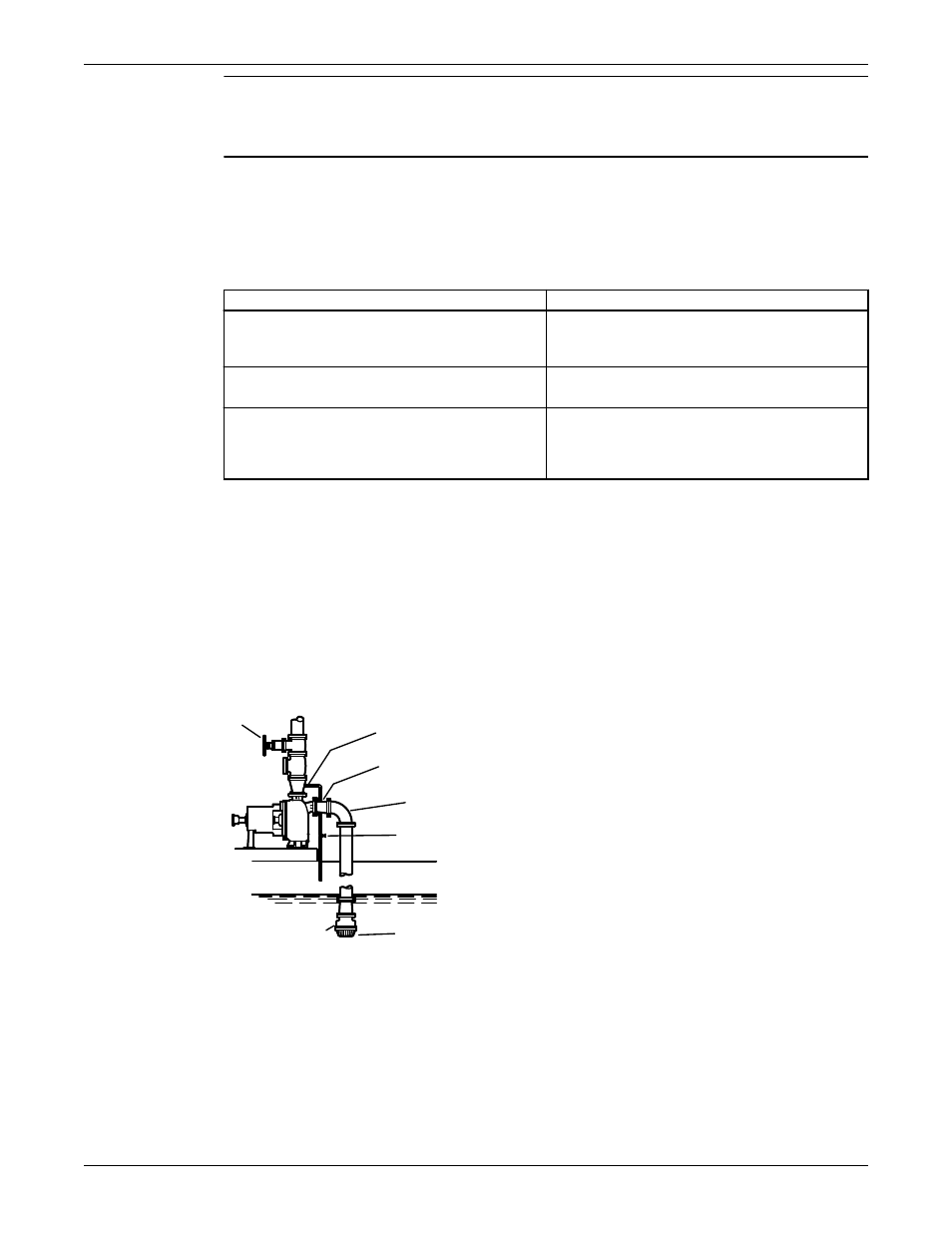

This illustration is an example of priming a 3796 pump in a pressurized system.

3796 Priming in a

Pressurized System

1

2

3

4

5

6

7

1.

By-pass line

2.

Concentric reducer

3.

Long radius elbow

4.

Shutoff valve

5.

Strainer

6.

Foot valve (if used)

7.

Discharge isolation valve

Figure 16: Priming a 3796 pump

Commissioning, Startup, Operation, and Shutdown (Continued)

Model 3796 i-FRAME Installation, Operation, and Maintenance Manual

59