Goulds Pumps 3796 i-FRAME - IOM User Manual

Page 116

Table 22: Lubricating-grease requirements

Pumpage temperature less than

350°F (177°C)

Pumpage temperature greater

than 350°F (177°C)

NGLI consistency

2

3

Mobil

Mobilux EP2

SCH32

Exxon

Unirex N2

Unirex N3

Sunoco

Mutipurpose 2EP

N/A

SKF

LGMT 2

LGMT 3

Convert from greased-for-life or regreaseable to oil-lubricated bearings

1. Remove the plug from the oil-return slot in the frame located under the radial bearing. Use this table

as a guide.

Pump model

Action

STi

Remove the epoxy from the return slot.

MTi, LTi

Remove the set screw installed in the oil-return hole.

2. Remove the plug from the oil-return hole in the bearing housing (134).

NOTICE: For the LTi, the bearing housing (134) and clamp ring (253B) require replacement. Failure

to do so may result in decreased performance.

3. Replace both bearings with unshielded, oil-lubricated bearings.

Table 23: Bearing types

Frame

Inboard bearing

Outboard bearing

Double row

Duplex

STi

6207

3306

7306

MTi

6309

3309

7309

LTi

6311

Not applicable

7310

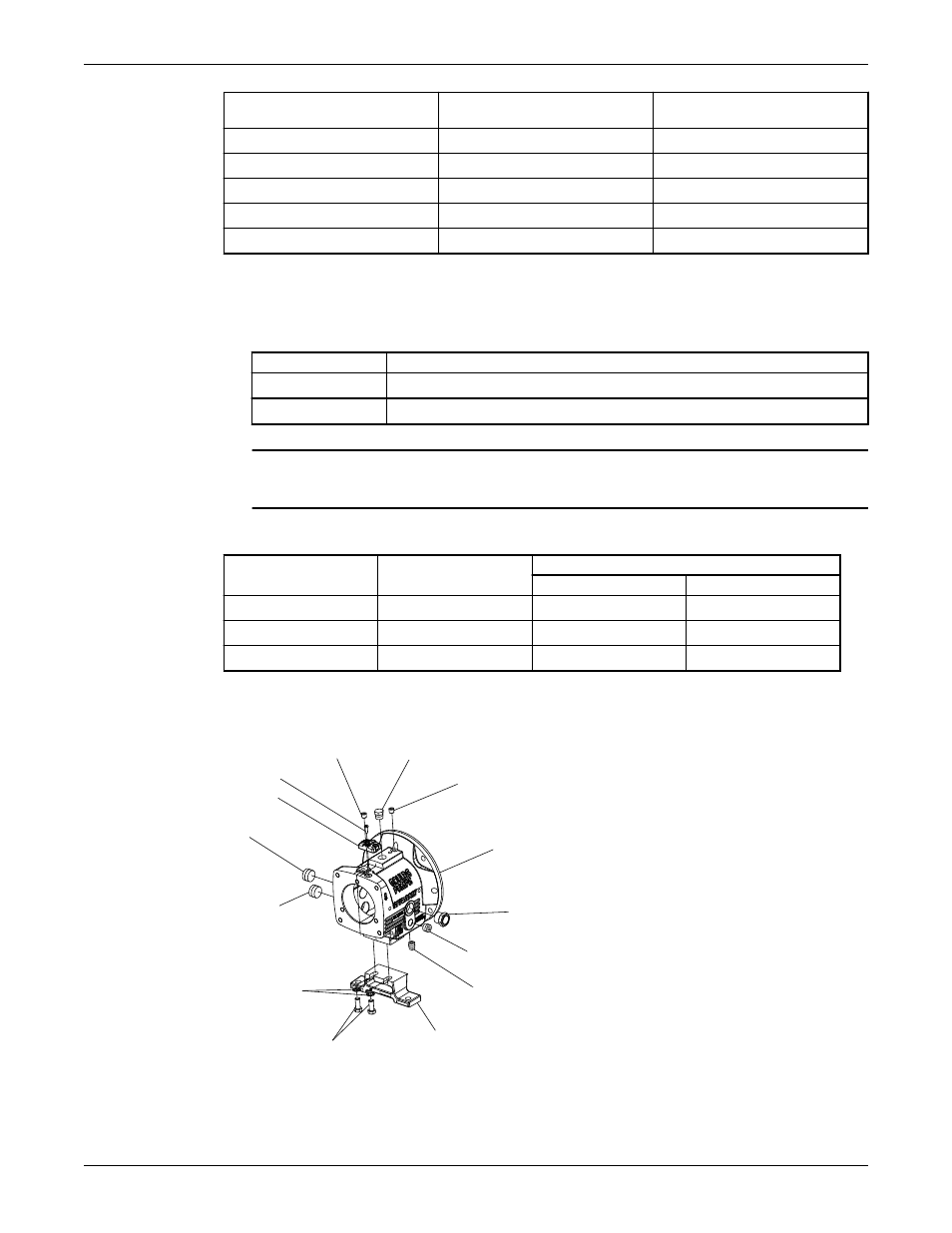

4. Remove the grease fittings (193) to prevent accidental greasing.

Two plugs (408H) are required to replace the two grease fittings.

529

370F

241

408A

408L

319

228A

408W

113A

408W

372T

408N

408M

761B

Maintenance (Continued)

114

Model 3796 i-FRAME Installation, Operation, and Maintenance Manual