Install the rotating element, Confirm the seal chamber runout – Goulds Pumps 3620 - IOM User Manual

Page 76

Maintenance

API limits are listed in the Shaft and rotor runout requirements table.

Install the rotating element

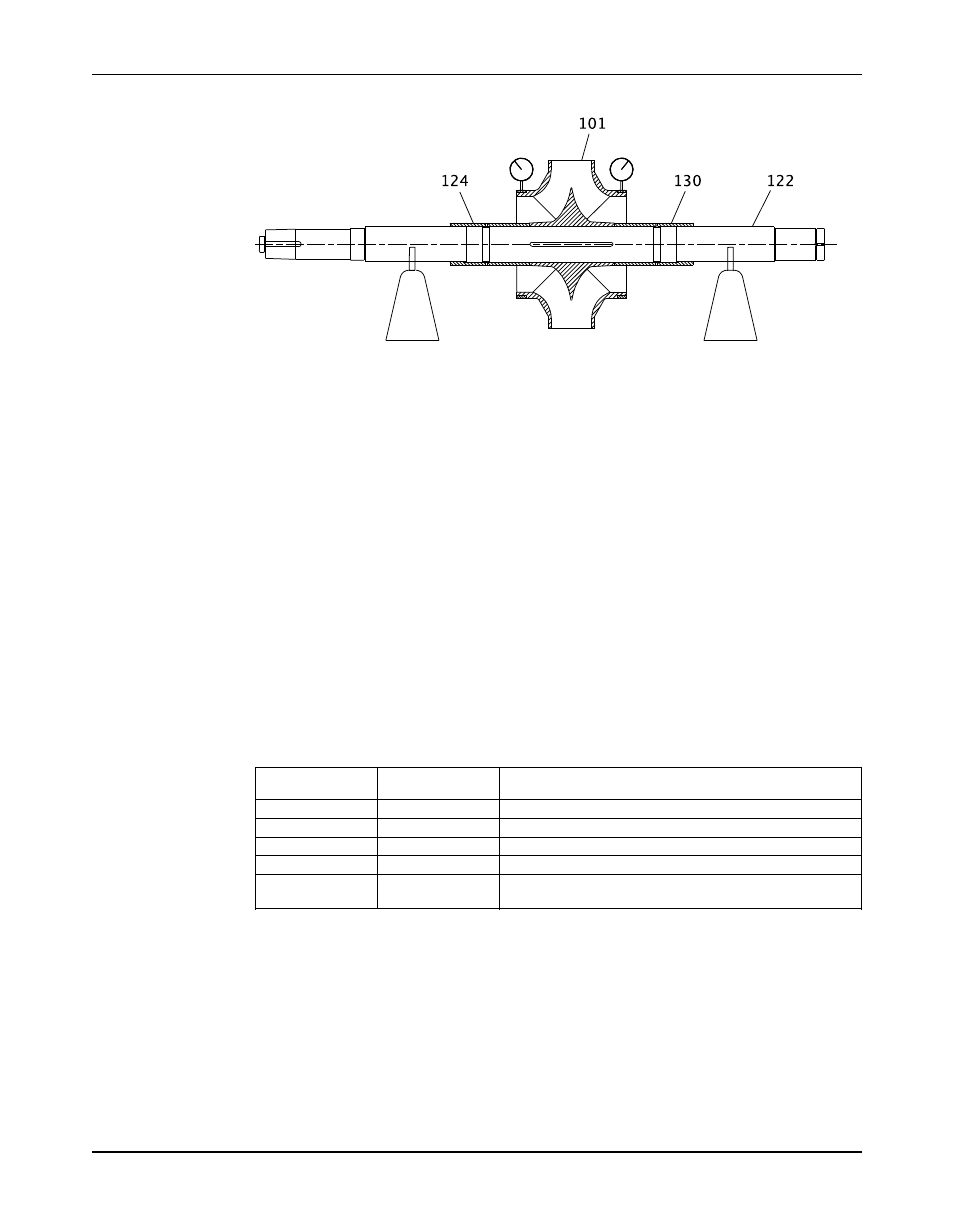

Confirm the seal chamber runout

The bearing housings are doweled to the

head (184) and

casing (100) during the original build. However, in order to assure the correct running position

of the shaft, use this procedure in order to confirm the seal chamber runout before you install

the cartridge mechanical seals:

1. Install the old bearings on the shaft and bolt the bearing housings to the casing and head.

2. Mount the dial indicator on the shaft (122). Rotate the shaft (122) so that the indicator rides

along the seal chamber bore for 360°.

3. If the total indicator reading exceeds 0.005 in. (0.127 mm), determine the cause and make

corrections.

It may be necessary to readjust the housing.

a) Remove the dowel pins and use the adjusting screws to bring the runout to within 0.002

in. (0.0508 mm).

b) Redowel the housings in a different location.

4. Check the seal-chamber face runout.

a) With a dial indicator mounted on the shaft, rotate the shaft so that the indicator rides

along the seal-chamber face for 360°.

b) If the total indicator reading exceeds the allowable runout as this table shows,

determine the cause and make corrections.

Frame group

Nameplate radial

Maximum allowable total indicator reading in inches

bearing

(millimeters)

S

6309

0.0020 (0.0508)

M / MX

6312

0.0025 (0.0635)

L / LX

6313

0.0030 (0.0762)

XL

6318

0.0035 (0.0889)

X, XX, XXL, XLX

6320

0.0035 (0.0889)

6224

5. Remove the dowel pins and unbolt the bearing housings. Discard the old bearings.

74

Model 3620, API Type BB2 Single Stage / ISO 13709 1st/2nd Ed. / API 610 8th-11th Ed. Installation, Operation, and

Maintenance Manual