Preassembly inspections, Replacement guidelines – Goulds Pumps 3620 - IOM User Manual

Page 66

Maintenance

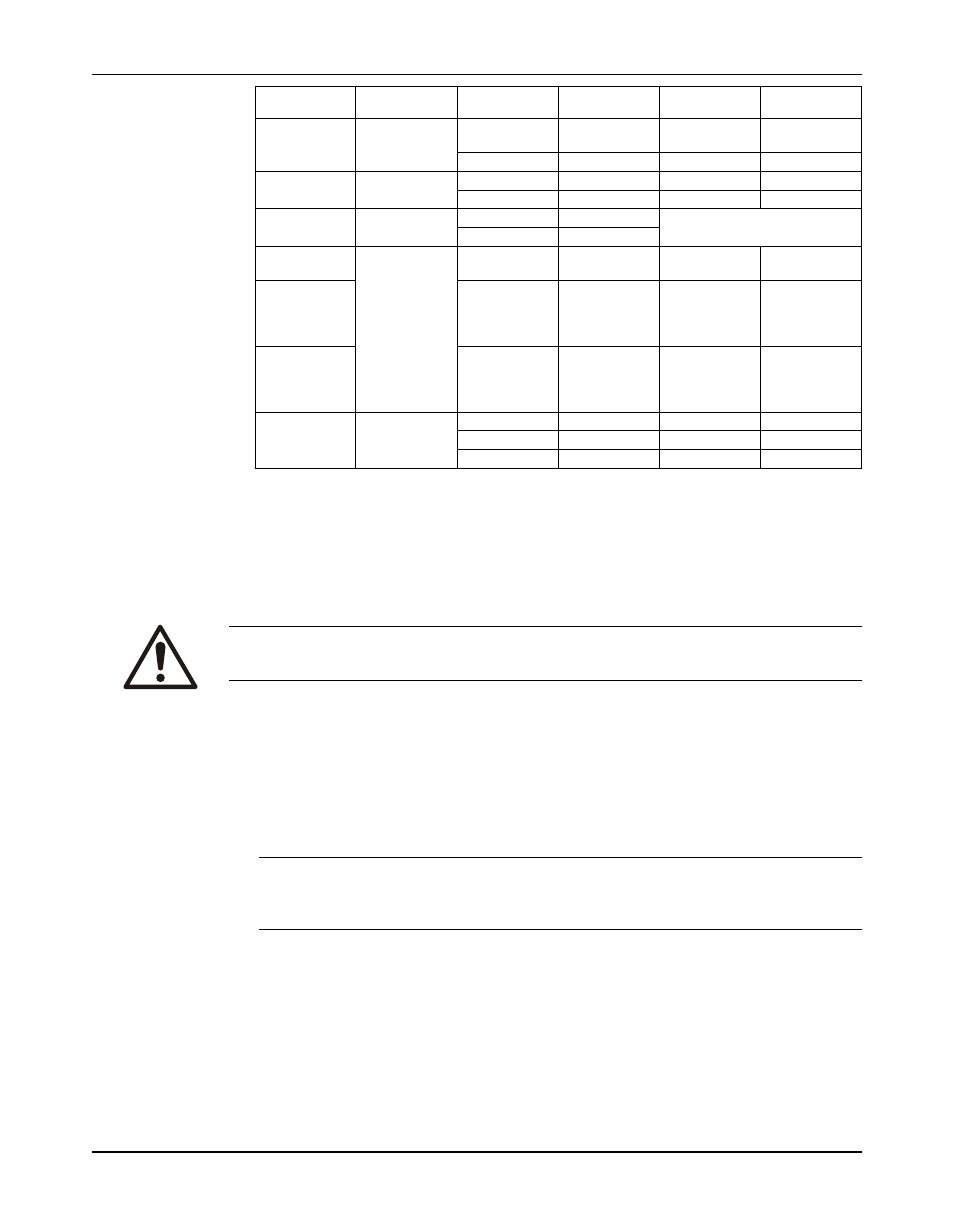

Frame group

Nameplate

Size

Ball/ball

Sleeve/ball

KTB

radial bearing

arrangement

arrangement

arrangement

10x12-17SQ

15.19 (386)

20.66 (525)

10x12-18SQ

M / MX

6312

All others

13.12 (333)

14x16-20Q

16.31 (414)

22.36 (568)

L / LX

6313

All others

15.19 (386)

20.66 (525)

18x20-21

17.75 (441)

XL

6318

All others

16.31 (414)

18x20-24

22.38 (568)

29.12 (740)

X

20x24-30

28.75 (718)

14x16-22

16x18-17

XXL

20.50 (521)

27.38 (695)

18x20-22

6320

20x24-25

8x14-31

14x18-30

XLX

15.81 (402)

10x16-30

12x18-26

14x20-26

19.75 (502)

26.5 (673)

XX

6224

14x20-30

20.75 (527)

27.5 (699)

12x20-34

19.62 (498)

26.38 (670)

13. Remove the impeller (101).

Preassembly inspections

Replacement guidelines

Casing check and replacement

WARNING:

Avoid death or serious injury. Leaking fluid can cause fire and/or burns. Inspect and assure gasket sealing

surfaces are not damaged and repair or replace as necessary.

Inspect the casing and head for cracks and excessive wear or pitting. Thoroughly clean gasket

surfaces and alignment fits to remove rust and debris.

Repair or replace these parts if you notice any of these conditions:

• Localized wear or grooving that is greater than 1/8 in. (3.2 mm) deep

• Pitting that is greater than 1/8 in. (3.2 mm) deep

• Irregularities in the casing-gasket seat surface

• Wear ring clearances that exceed the values in the Minimum running clearances table

NOTICE:

When clearances between the rings become excessive (increase by 50%), hydraulic

performance decreases substantially.

Casing areas to inspect

The arrows point to the areas to inspect for wear on the casing:

64

Model 3620, API Type BB2 Single Stage / ISO 13709 1st/2nd Ed. / API 610 8th-11th Ed. Installation, Operation, and

Maintenance Manual