Dowel for motor installation, Dowel for cold service – Goulds Pumps 3620 - IOM User Manual

Page 49

Commissioning, Startup, Operation, and Shutdown

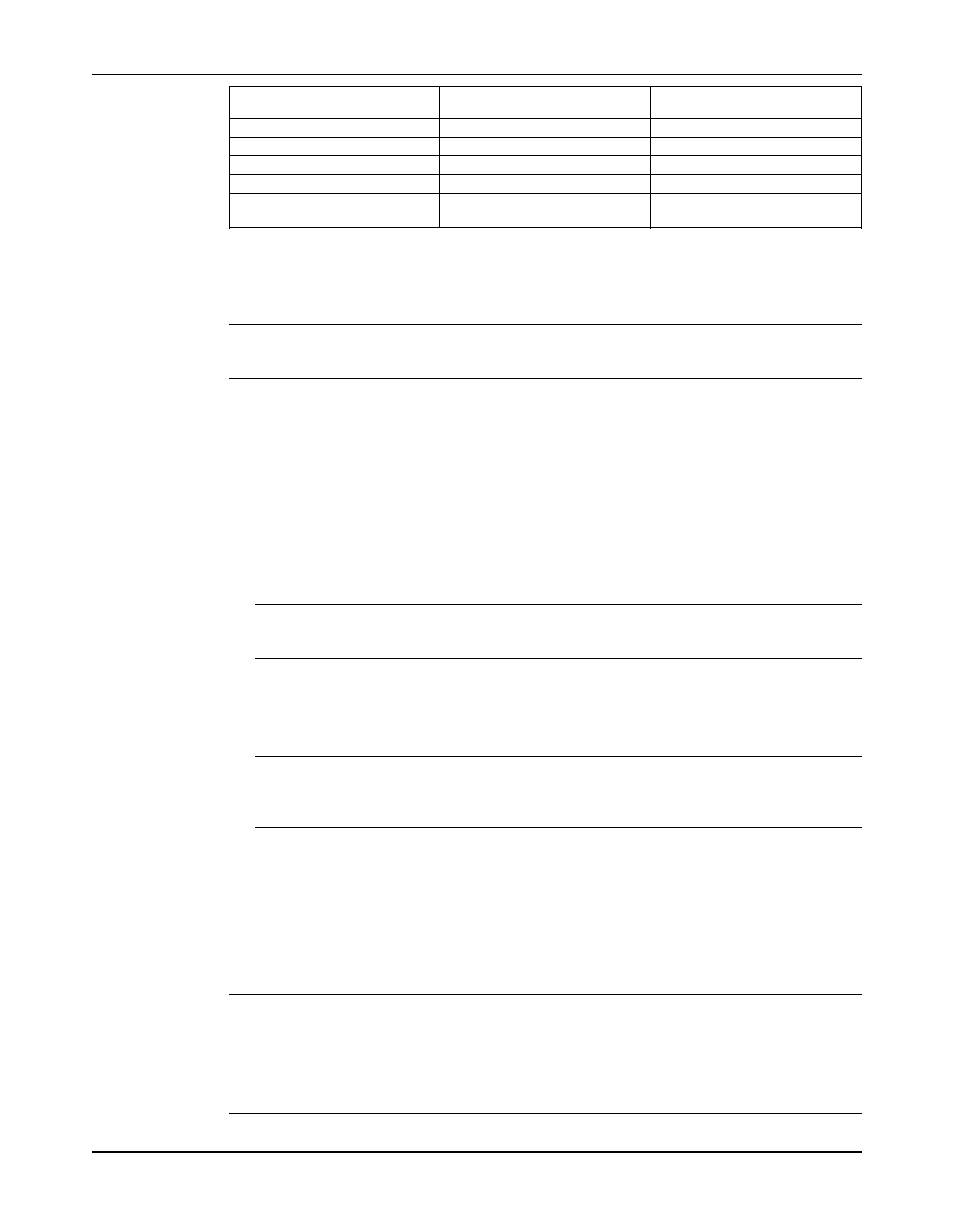

Frame group

Nameplate radial bearing

Temperature threshold for hot

doweling

S

6309

680°F (360°C)

M / MX

6312

570°F (300°C)

L / LX

6313

450°F (230°C)

XL

6318

390°F (200°C)

X, XX, XXL, XLX

6320

330°F (165°C)

6224

When the driver is mounted at the factory, the pump is doweled for both cold and hot

applications; the driver is not doweled in order to allow for final field alignment. When the driver

is mounted in the field, the pump is not doweled. Therefore, these doweling procedures,

typically done at the factory, must be done in the field.

NOTICE:

You should dowel only after completing the final alignment.

Dowel for motor installation

1. Center the pump on its pedestal so that the hold-down bolts are centered in the tapped

holes of the pump pedestal.

2. Place the motor on the baseplate with the proper shaft separation (DBSE = distance

between shaft ends).

3. Tighten the pump hold-down bolts.

4. After you have determined the correct motor location on the motor pedestals, mark the

location of the motor on the pedestals with a hole punch through the hold-down bolt holes

in the motor feet.

5. Remove the motor, then drill and tap the punched holes on the motor pedestal.

NOTICE:

Scribe the motor shims in order to return them to the correct location on the motor pedestal.

6. Set the motor back onto the baseplate with the shims in the correct location. Tighten the

hold-down bolts.

7. Loosen the pump and motor hold-down bolts. Confirm that the pump and motor are not

bolt-bound in order to make sure that the final drilled holes will be correctly located.

NOTICE:

Do not dowel the pump prior to this procedure because you will not be able to move the

pump on its pedestals.

Dowel for cold service

Required tools:

• Two number 7 taper pins

• One number 7 taper pin reamer

• 21/64 in. or "Q" size drill

• Hardwood block or soft-faced hammer

NOTICE:

• This procedure must be done only after the pump is properly aligned with the driver on the

baseplate.

• If water-cooled pedestals have been provided, then do not drill through the baseplate

pedestal. Doing so can result in leakage of cooling water.

Model 3620, API Type BB2 Single Stage / ISO 13709 1st/2nd Ed. / API 610 8th-11th Ed. Installation, Operation, and

47

Maintenance Manual