Permissible coupling misalignment – Goulds Pumps 3410 - IOM User Manual

Page 23

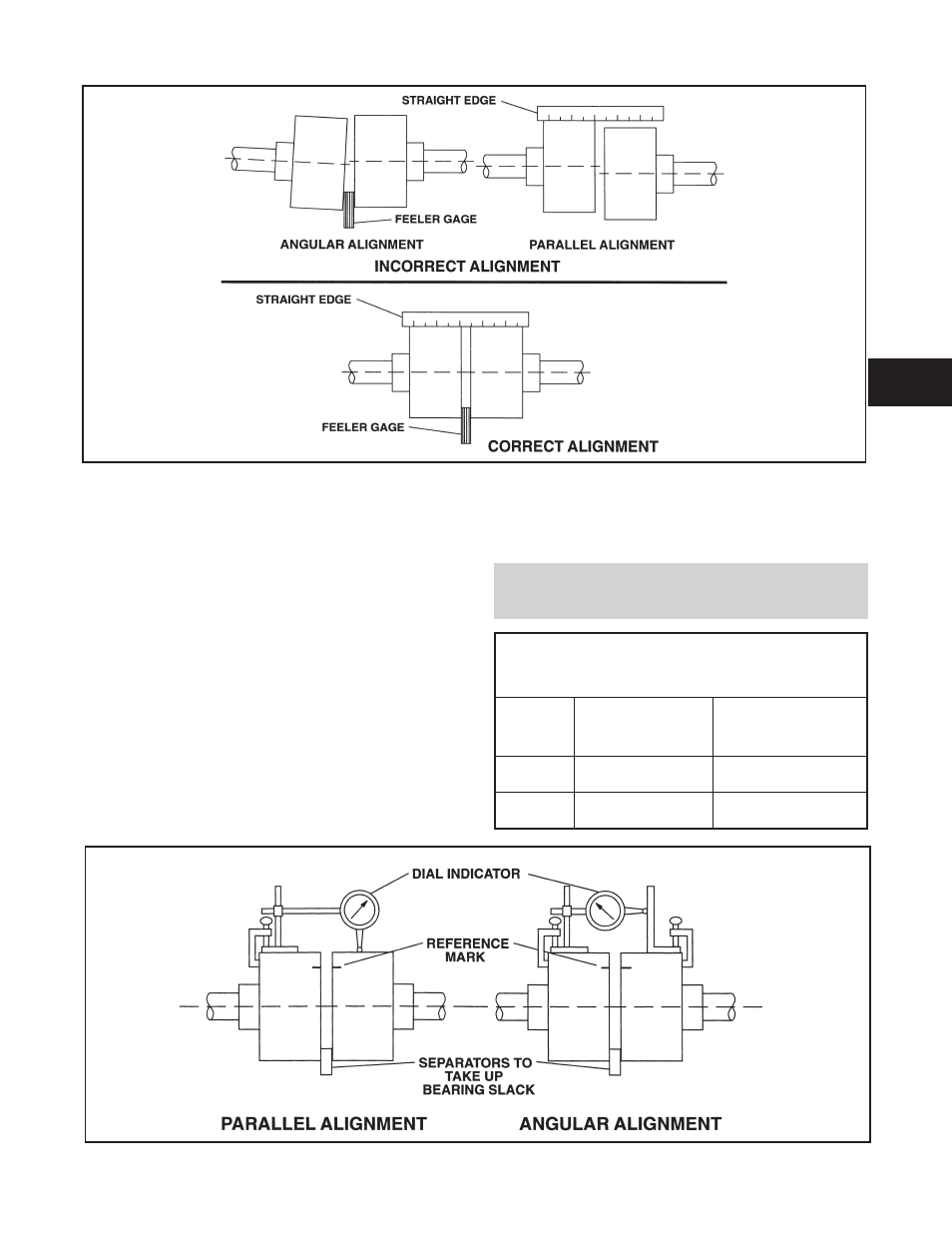

Method 2 - Dial Indicators (Fig. 12):

A dial indicator can be used to attain more accurate

alignment.

Fasten the indicator stand or magnetic base to the pump

half of the coupling and adjust the assembly until the

indicator button is resting on the other half coupling

periphery.

Set the dial to zero and chalk mark the coupling half where

the button rests. Also place a separator between the

coupling halves so bearing slack does not affect the

readings. (Chalk and separators are not necessary on the

elastomeric couplings that have not been disconnected.)

Rotate both shafts by the same amount; i.e., all readings

must be made with the button on the chalk mark.

The dial readings will indicate whether the driver has to be

raised, lowered or moved to either side. Accurate alignment

of shaft centers can be obtained with this method even

where faces or outside diameters of the coupling are not

square or concentric with the bores. After each adjustment,

recheck both parallel and angular alignments.

NOTE: Gross deviations in squareness or

concentricity may cause rotation unbalance problems

and if so must be corrected.

PERMISSIBLE COUPLING

MISALIGNMENT

Single Element

Coupling

Double Element

(spacer) Coupling

Parallel

.004” TIR

(4 mils)

.060” TIR

per foot of spacer length

Angular

.004” TIR

per inch of radius.

.002” TIR

per inch of radius

3410 IOM 1/2010

21

Fig. 10

Fig. 11

Fig. 12

3