Nilfisk-ALTO RS 850 User Manual

Page 145

USER MANUAL

ENGLISH

RS 850

33014576(4)2008-02 A

31

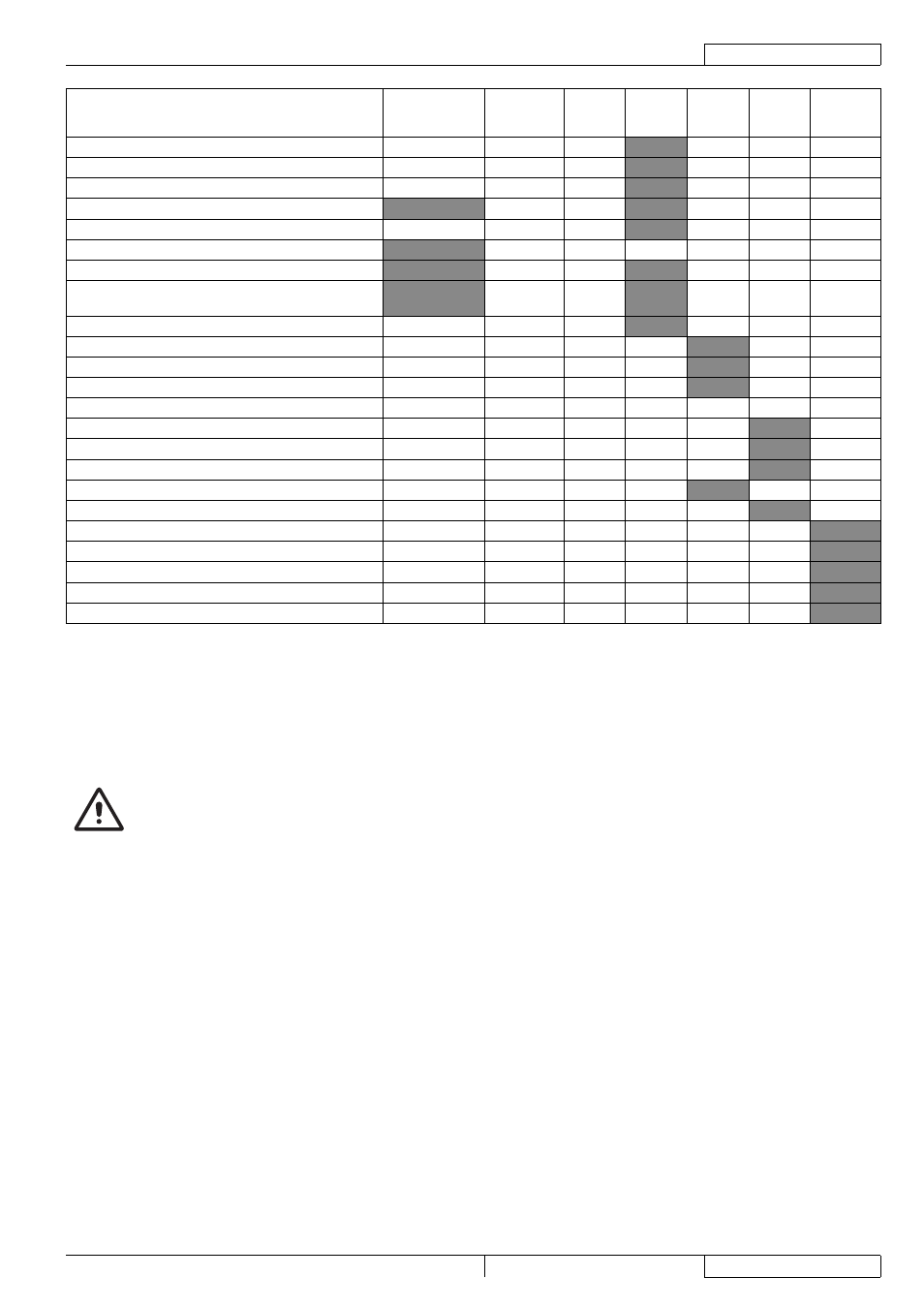

Maintenance

Running-in pe-

riod (after the

fi rst 50 hours)

Every 10

hours or

before use

Every

150

hours

Every

300

hours

Every

500

hours

Every

1,000

hours

Every

2,000

hours

Engine oil change

(3)

Diesel engine oil fi lter replacement

(3)

Fuel fi lter element replacement

(3)

Nut and screw tightening and leakage check

(8)

(8)

Lubrication

(8)

Engine coolant line check

(8)

Hydraulic system oil suction fi lter replacement

(8)

(8)

Hydraulic system oil drain fi lter and tank breather fi lter

replacement

(8)

(8)

Engine fuel fi tting and screw tightening

(8)

Glow plug check

(8)

Injector check, cleaning and calibration

(8)

Engine air fi lter replacement

(8)

Climate control system air fi lter replacement

Alternator and fan belt replacement

(8)

Climate control system belt replacement

(8)

Fuel tank cleaning

(8)

Engine coolant change

(4) (8)

Hydraulic system oil change

(3) (8)

Starter carbon brush check

(8)

Brake system check

(8)

Turbocharger check

(8)

Minor engine overhaul

(5) (7) (8)

Major engine overhaul

(6) (7) (8)

(3) Or every year

(4) Or every two years

(5) After 4,000 hours

(6) After 8,000 hours

(7) Contact an authorised VM Motori S.p.A. workshop.

(8) For the relevant procedure see the Service Manual, at any Nilfi sk Service Center.

HOPPER, FILTER AND SUCTION PIPE CLEANING, GASKET CHECK AND SUCTION FAN BEARING

LUBRICATION

WARNING!

Protect body parts (eyes, hair, hands, etc.) properly, when performing cleaning procedures using compressed

air or water gun.

Preliminary operations

Empty the hopper (7, Fig. G), drive the machine to a cleaning/washing appointed area, then engage the parking brake (13, Fig.

E).

Lift and dump the hopper (7, Fig. G), according to the procedure shown in the relevant paragraphs.

Install the lid support rod (17, Fig. F), according to the instructions shown on the relevant paragraph.

Hopper cleaning (after every use)

Clean the hopper (1, Fig. F) and the defl ector (14) with pressurized water.

Carefully check the suction sealing gasket (19, Fig. F) for integrity, and replace it if necessary.

1.

2.

3.

4.

5.