Systems overview, Supply side, Supply side, continued – Pulsafeeder Pre-Engineered Skid Systems User Manual

Page 7: Pre-engineered skid systems, Installation, operation and maintenance manual

Pre-Engineered Skid Systems

Installation, Operation and Maintenance Manual

PES00039, Rev. B

System Overview

Page 7

Systems Overview

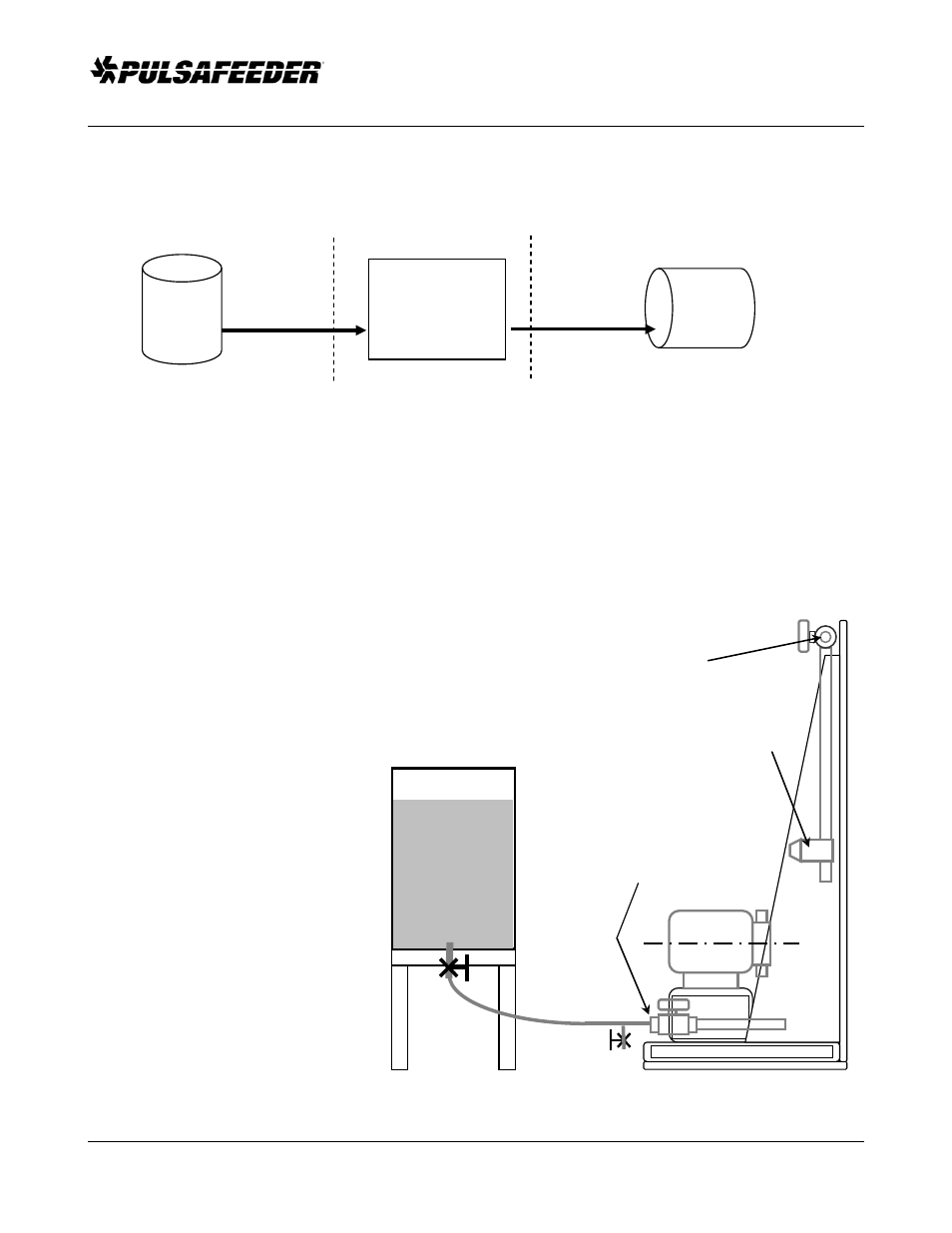

The Pulsafeeder Pre-Engineered Skid System is designed to pump chemicals at precisely controlled

rates into another process or system.

Proper arrangement of piping and appurtenances on both the supply side and the process side are

critical to the successful operation of the overall system. These are the responsibility of the

owner/operator of the system, and attention should be paid to the comments, below:

Supply Side

Dosing chemicals are usually sourced from a barrel or tote container. The source may be located

above the centerline of the pump(s) which is referred to as a “flooded suction” or it may be located

slightly below the centerline of the pump(s) which is referred to as “suction lift.” Connections to and

from the Solution Tank are most commonly made with flexible hose or tubing although they may be

made with hard piping. Solution Tank should be covered to prevent contamination.

Dosing

Chemical

Served

Process or

System

Pulsafeeder

Skid System

Supply

Side

Process

Side

Pump

Skid

Suction

Connection

Solution

Tank

Pressure

Relief

Valve

Supply

Line

Figure 3

Flooded Suction

Skid Outlet

Connection

Flooded Suction

This is the most trouble free type of

installation. Since the Supply Line tubing is

filled with chemical, priming is

accomplished quickly and the chance of

losing prime is reduced.

Recommended for very low flow rate

applications. e.g. 2 ml/hr, or where

pumping solutions such as sodium

hypochlorite or hydrogen peroxide which

can form air bubbles.

Supply Line should gradually slope

downward from the Solution Tank to the

Skid Suction Connection.

It is strongly recommended to add a drain

provision on the suction side to facilitate

emptying and flushing of the system for

maintenance.

Drain