Initial prime, continued, System with suction lift, Pre-engineered skid systems – Pulsafeeder Pre-Engineered Skid Systems User Manual

Page 14: Installation, operation and maintenance manual, Pump

Pre-Engineered Skid Systems

Installation, Operation and Maintenance Manual

PES00039, Rev. B

Initial Prime

Page 14

Initial Prime, Continued…

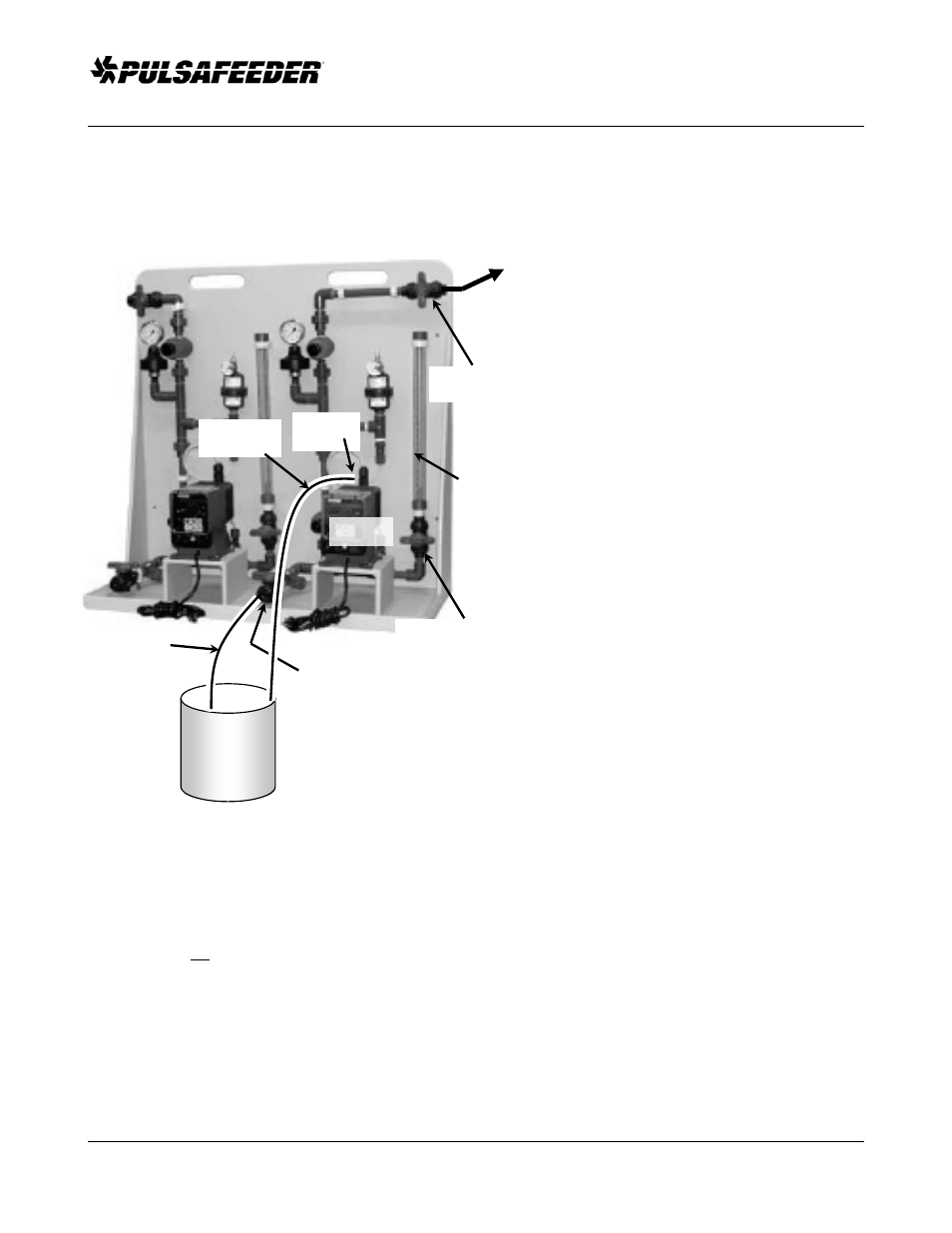

System with Suction Lift

With a suction lift configuration, the

entire suction arrangement (suction

line and Skid suction piping) as well

as the pump must be purged of air

before the pump can function. The

pump can evacuate the air, however

this may take considerable time.

Optional:

If the dosing chemical can be

handled safely, it may be helpful to

add dosing chemical to the suction

assembly via the top of the calibration

column. This requires the installation

of a foot valve at the entrance to the

suction line within the chemical

source container. Open the Air Bleed

Valve turning the opening knob

counterclockwise (see Figure 9).

Open Column Isolation Valve. Open

all valves in the Suction Line. Add

dosing chemical into the top of the

Calibration Column until liquid

remains visible. Follow steps, below.

Note that Air Bleed Valve is open.

1. Close Skid Discharge Valve and Column Isolation Valve

2. Open Air Bleed Valve (turn opening knob counterclockwise, see Figure 9)

3. Open all valve(s) on the suction side – Skid Suction Connection Valve and any valve(s) in your

suction line

4. Connect pump/motor to power source (pump/motor off)

5. Start pump using manufacturer’s recommendations for initial operation settings

6. Observe flow through Air Bleed Bypass. When solid stream (no air bubbles) is observed,

pump is primed.

7. Shut off pump.

8. Close Air Bleed Valve (turn opening knob clockwise)

Figure 11

Pump and Suction System Setup for Prime

Suction Lift Configuration

Chemical

Source

Suction Line

Pump

Skid Discharge

Connection/Valve

Column Isolation

Valve

Discharge Line

to Process

Skid Suction

Connection/Valve

Air Bleed

Bypass Line

Air Bleed

Valve

Calibration

Column