Flow calibration, Filling calibration column – Pulsafeeder Pre-Engineered Skid Systems User Manual

Page 18

Pre-Engineered Skid Systems

Installation, Operation and Maintenance Manual

PES00039, Rev. B

Pump Flow Calibration

Page 18

Flow Calibration

Chemical metering systems are designed to provide chemicals to a process at precise flow rates.

Metering pump output (flow rate) can be set as a function of both stroke length and stroke frequency.

A Calibration Column is used to determine pump flow rate and to enable flow rate adjustments. The

column must be filled with the dosing chemical prior to performing the calibration.

A description of the Calibration Column and the calibration procedure is shown on Page 20. Review

this before proceeding with the next steps.

Filling Calibration Column

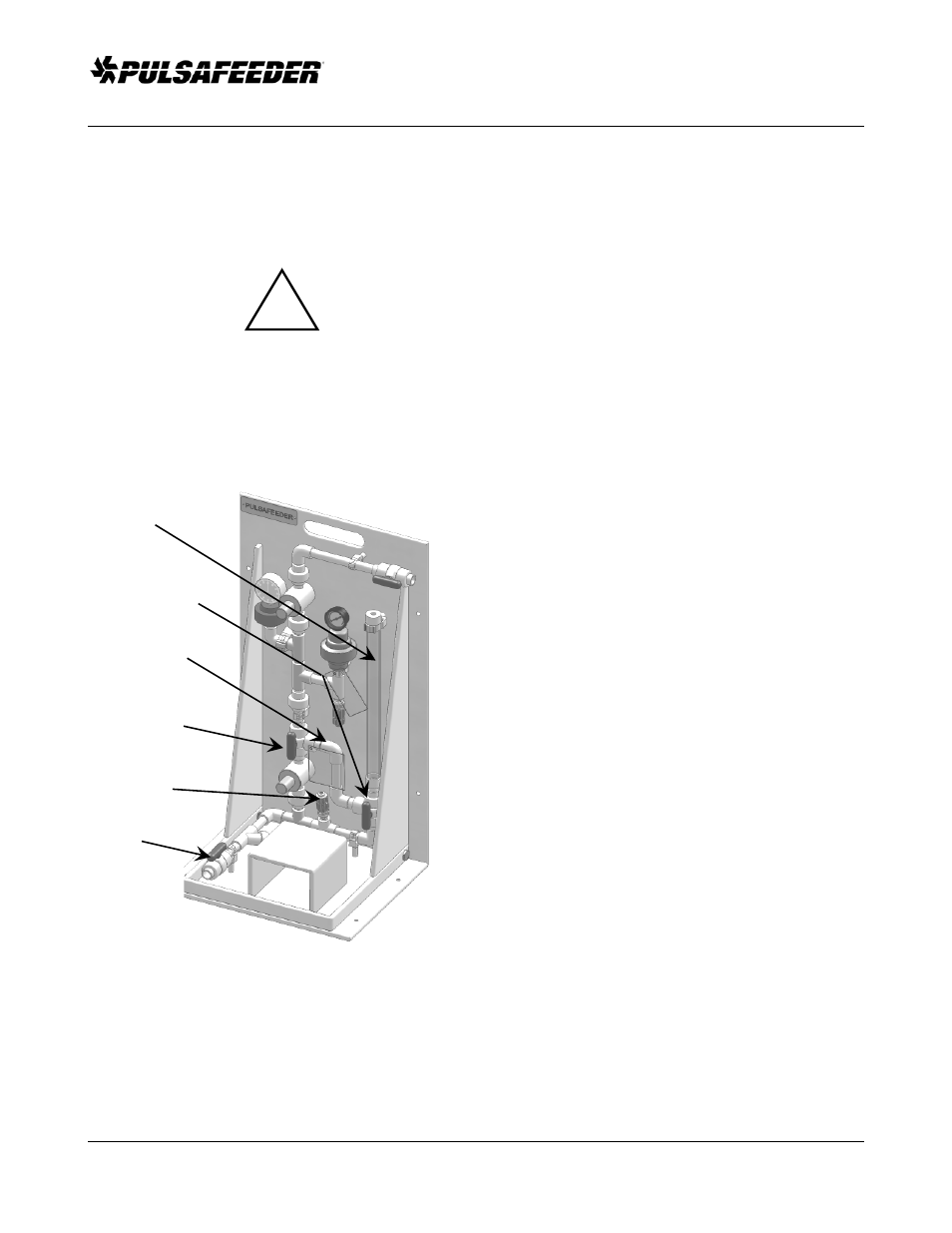

For a skid system with a cross-connect, the

Calibration Column is filled by the pump.

See Figure 15, at left.

1. Turn the Column Isolation Valve to allow

flow from the cross-connect into the

Calibration Column.

2. Then turn the Flow Diverter Valve to direct

flow from the Discharge Header through the

cross-connect and into the Calibration

Column.

3. Once the liquid level in the Calibration

Column reaches slightly above the topmost

scale mark, turn the Flow Diverter Valve to

re-direct flow into the system. Do not

overfill.

4. Close Column Isolation Valve.

5. Calibration Column is filled and ready for the

calibration procedure.

Note: While the Calibration Column is being filled in

this manner, dosing chemical will not be provided to

the served process.

!

CAUTION

Use extreme care when handling chemicals.

Avoid any spray, splatter or spilling.

Always wear appropriate protective clothing.

Flow Diverter

Valve (3-way)

Column Isolation

Valve (3-way)

Skid Suction

Valve

Pump Suction

Connection

Cross-connect

Calibration

Column

Figure 15

Skid System with Cross-connect