Flow calibration procedure, Pre-engineered skid systems, Installation, operation and maintenance manual – Pulsafeeder Pre-Engineered Skid Systems User Manual

Page 20

Pre-Engineered Skid Systems

Installation, Operation and Maintenance Manual

PES00039, Rev. B

Pump Flow Calibration

Page 20

Flow Calibration Procedure

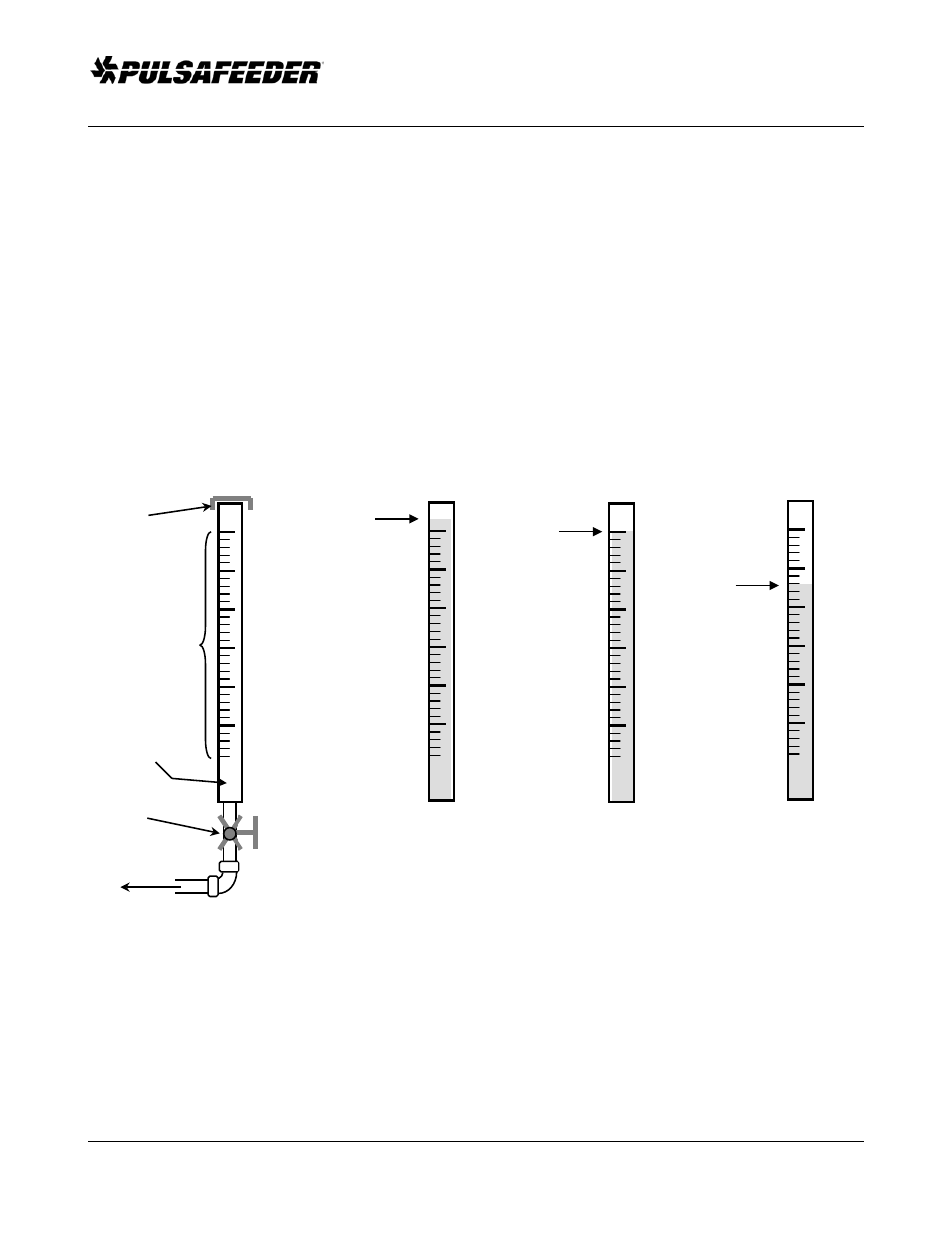

The Calibration Column is filled to slightly above the top mark of the scale. The pump is then run in

the system while being fed from the Calibration Column. After a 30 second time period, the liquid

level reading on the scale will be a direct readout of the pump flow rate in US Gallons/hr. (Note that a

milliliter scale is also shown on the Calibration Column)

With the pump running in the system

1. Open the Column Isolation Valve so that the column feeds into the suction header, and

immediately close the Skid Suction Valve (see Figures 15 and 16)

2. Observe the liquid level in the Calibration Column. When it reaches the top scale mark, begin

timing.

3. Allow 30 seconds to pass.

4. Open the Skid Suction Valve and immediately close the Column Isolation Valve

5. Read pump output flow rate directly on the scale in US Gallons/hr.

Once the calibration is complete, compare the reading to the desired rate for your system. Refer to

your pump operation manual and adjust flow rate up or down accordingly (this is usually done by

changing stroke frequency). After pump adjustment is made, repeat calibration procedure. Continue

until the desired flow rate is achieved.

Scale

Cover

Valve

To Pump

Suction

Calibration

Column

Figure 17

Calibration Column

Start

Calibration

Procedure

Start

Timing

End of

30 Second

Time Period

Figure 18

Liquid Levels During Calibration

Top Scale

Mark

Beginning

Level

Read Pump

Output Rate