Skid layout and components, Pre-engineered skid systems, Installation, operation and maintenance manual – Pulsafeeder Pre-Engineered Skid Systems User Manual

Page 6

Pre-Engineered Skid Systems

Installation, Operation and Maintenance Manual

PES00039, Rev. B

Skid Layout and Components

Page 6

Skid Layout and Components

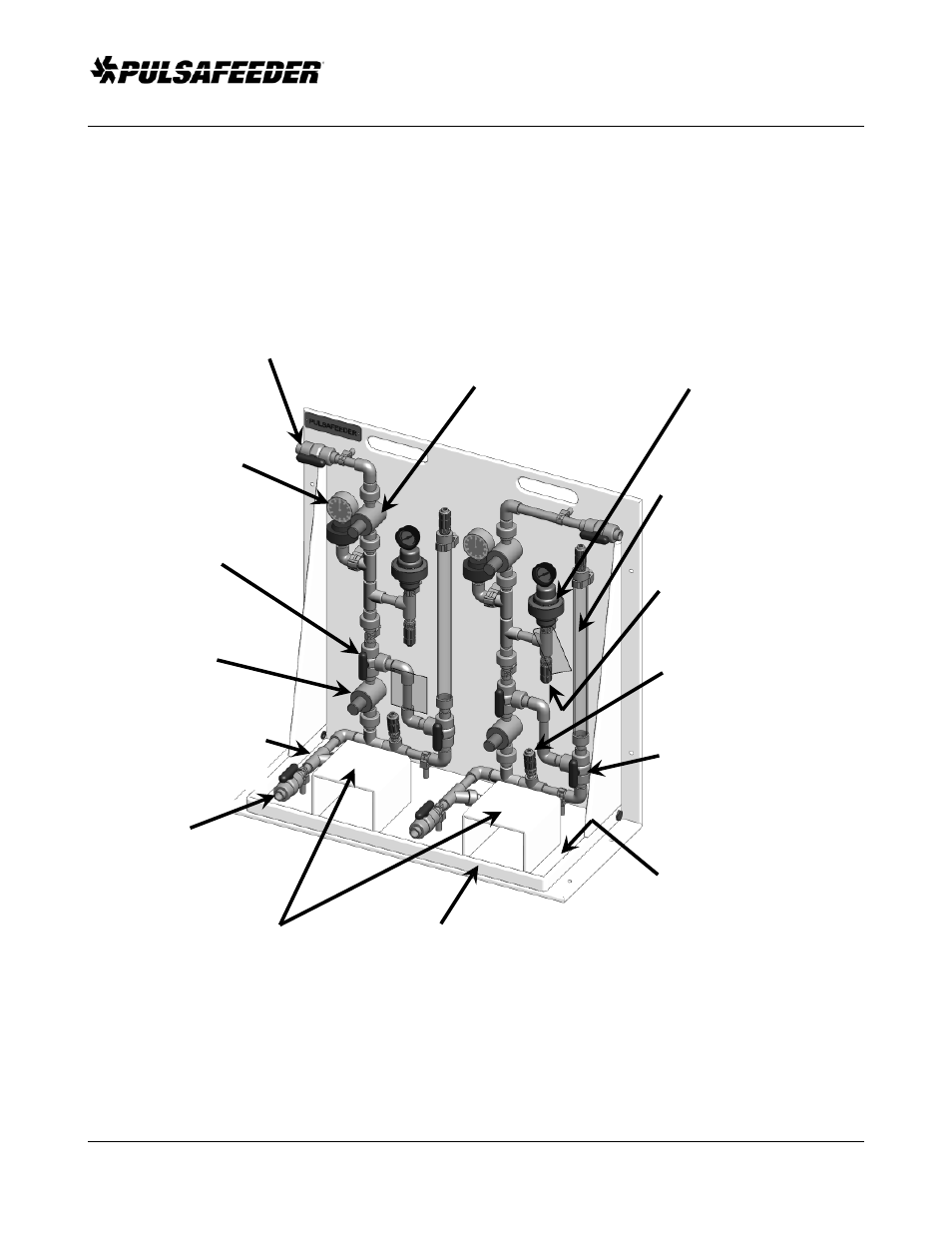

Figure 2, below, illustrates a dual pump skid system (Pulsafeeder Designation “2A”) for flooded

suction (chemical source above the pump centerline) as shown on Page 7. This system can be used for

two different chemicals or for redundant pump operation with one chemical. Your skid system may be

less complex than this. Note the various components and their descriptions as they apply to your skid

system.

Discharge Isolation Valve

Two-way ball valve to isolate

skid from injection system

Pressure Gauge

Monitors pump discharge

pressure

Pressure Relief Valve

Protects pump and system

piping from over-

pressurization

Column Fill Valve

Three-way ball valve to

enable pump to fill

calibration column

Y-Strainer

Keeps solids from entering

system and damaging pump

or system components

Suction Isolation Valve

Two-way ball valve to

isolate skid from suction

supply

Back Pressure Valve

Provides constant system

discharge pressure and acts

as anti-siphoning valve

Pulsation Dampener

Reduces pulsations from

pump and evens pressure

in injection system

Calibration Column

Enables pump output

flow to be precisely

determined

Pump Discharge Connection

Usually tubing, attachment for

pump discharge to skid piping

Pump Suction Connection

Usually tubing, attachment for

pump suction to skid piping

Column Shut-off/Fill Valve

Three-way valve enables

column to be filled by pump

for calibration and isolates

column for normal operation

Pump Mounting Platform(s)

Provides sturdy support for

pump(s)

Drip Collection Sump

Catches any leakage from pump

or system components

Skid Frame

1/2" high density polyethylene (HDPE)

UV resistant, chemically inert

Figure 2

Skid Layout and Components