Pulsafeeder Pulsar ECA NEMA4X User Manual

Page 18

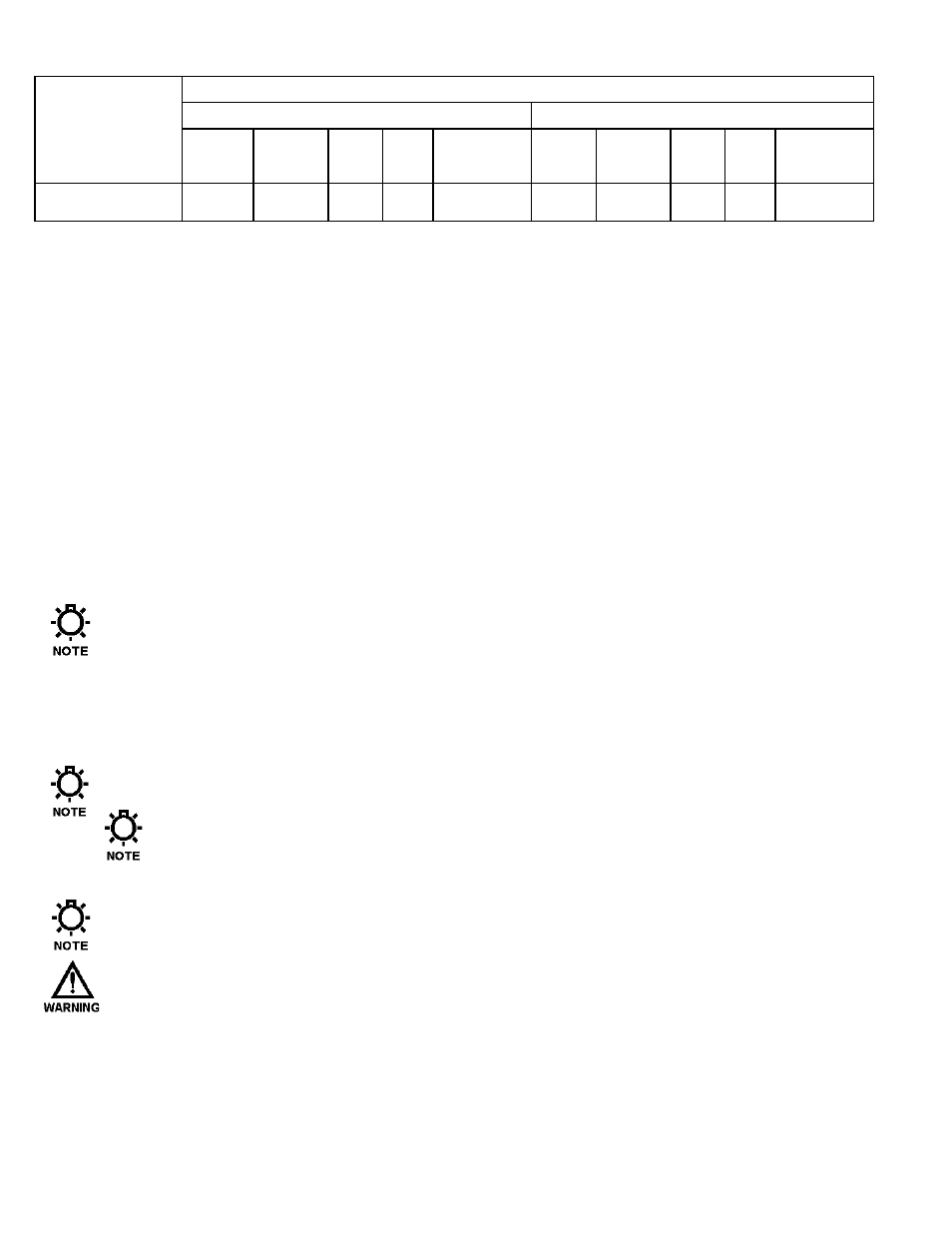

Power

Requirements

Recommended Minimum Wiring and Circuit Breaker

115 VAC Operation

230 VAC Operation

Actual

Circuit

Wire Wire

Safety

Actual

Circuit

Wire Wire

Safety

Draw

Breaker

Size

Size Approvals

1

Draw

Breaker

Size

Size Approvals

1

ECA

200ma

10A

14

AWG

2.5

mm

2

UL, CUL,

CE

200ma

10A

14

AWG

2.5

mm

2

UL, CUL,

CE

Note 1: UL File E217212, Applicable standards are CSA 22.2 14-23, Cenelec EN61326-1,

UL61010-1, and EN61010-1 3

rd

edition

Note the ECA input current ratings from the name plate and check the applicable electrical codes

for required wire type and size, grounding requirements, over-current protection, and incoming

power disconnect before wiring the controller. Connect the proper AC voltage supply to power the

ECA at connector J7. Neutral and Line connection points are indicated on the circuit board under

the connector. The Earth connection is made to the stud on the chassis via a ring terminal

(provided). See Figure 3 for details. Remove approximately 0.3 inches, (7-8mm) of insulation from

the end of each conductor. Loosen the terminal strip screw, and insert the stripped wire end fully

into the terminal. Tighten the screw to 5 in-lbs. (0.5 Nm) to secure the conductor. Make certain

that the terminal grips the wire, not the insulation

.

The operating voltage and frequency of the

ECA is factory configured -- an internal motor and capacitor are sized according to voltage and

frequency. If the power supplied to the unit does not match the factory configuration (shown on

the nameplate), it will malfunction/damage and void the warranty.

Note: Power wiring should have a rating of at least 300 volts AC (rms) and a temperature

rating of at least 105 Degrees C.

A circuit breaker or disconnect switch with fuses, must be provided in accordance with all

applicable local and national electrical codes and regulations. Size external fusing/breaker for

ratings for the wiring used for the unit.

Applicable national and local electrical codes take precedence over recommendations made here.

To ensure proper operation, the ECA should remain powered at all times. A dry

contact input provides the ECA with motor status (on vs. off). See Motor Status Input

Section

Input Power must be run in separate conduit. Do not combine Power and Control wires in

a common conduit!

Field Wiring conductors shall be copper conductors only!

12