Nor-Lake Ice Cream Hardening & Holding Cabinets Models NX362WWW/4 User Manual

Page 10

151555

Rev.

A

07/12

10

MANUAL DEFROST

Defrosting my also be induced manually by keeping the defrost button for 3 seconds. Once defrost

has started, the defrost will go through a defrost and drip time pull down cycle.

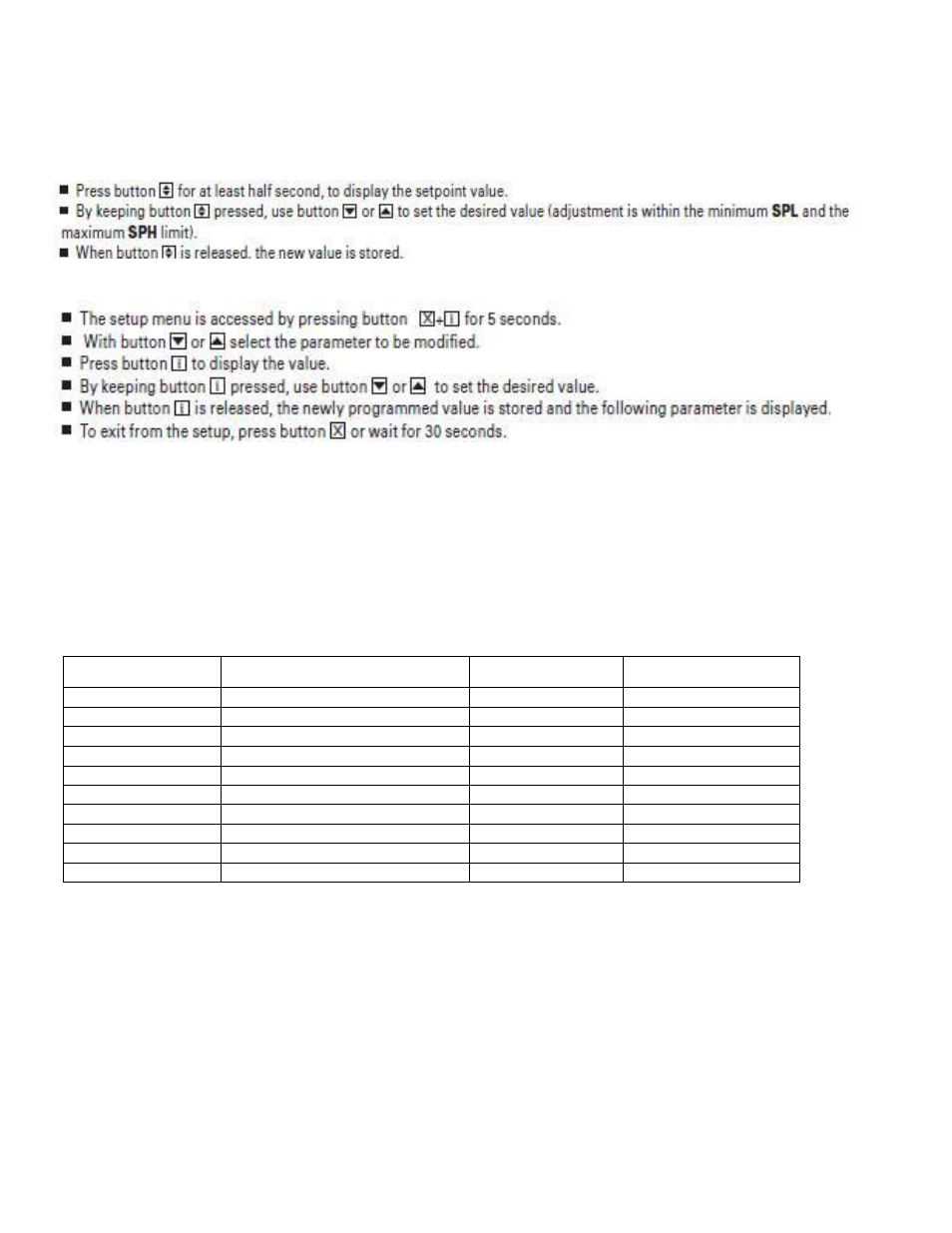

HOW TO CHANGE THE SETPOINT

HOW TO CHANGE A PARAMETER VALUE

NOTE 1: The set value is stored even when the procedure is exited by waiting the time-out to expire.

NOTE 2: The SETPOINT is set at a recommended –20°F at the factory.

NOTE 3: To scroll down the parameters without changing them, press the DOWN button.

LIST OF PARAMETERS

Here is a list of the parameters the value of which can be changed in the programming mode, as well

as their ranges.

Display Symbol

Parameter

Range

Factory Setting

SP Temperature Set Point

SPL.SPH

-20°F

HYS Temperature Differential

1 to 255°F

7°F

SPL Minimum

Temperature limit -35.SPH

-35°F

SPH Maximum

Temperature limit SPH.120°

15°F

AHA High Temperature alarm

-50.120°

35°F

ALA Low

Temperature Alarm

50.120°

-45F

ATD Temperature Alarm Delay

0.120min

30min

DFR

Number of Defrost Cycle per 0.24

4/day

DLI Defrost

Termination

-50.120°

55°F

DTO

Maximum Defrost Duration

1.120min

30min

ELECTRICAL CONNECTIONS

The controller is provided with screw terminal block to connect cables with a cross section up to 2,5

mm2. Before connecting cables make sure the power supply complies with the control’s requirements.

Separate the probe cables from the power supply cables, from the outputs and the power

connections. Do not exceed the maximum current allowed on each relay, in case of heavier loads use

a suitable external relay or contractor’s.