Maintenance and care – Karcher HDC advanced User Manual

Page 23

English

23

ƽ

Danger

Risk of injury! The main switch is to be switched off while carrying out any repairs or maintenance jobs.

Maintenance and care

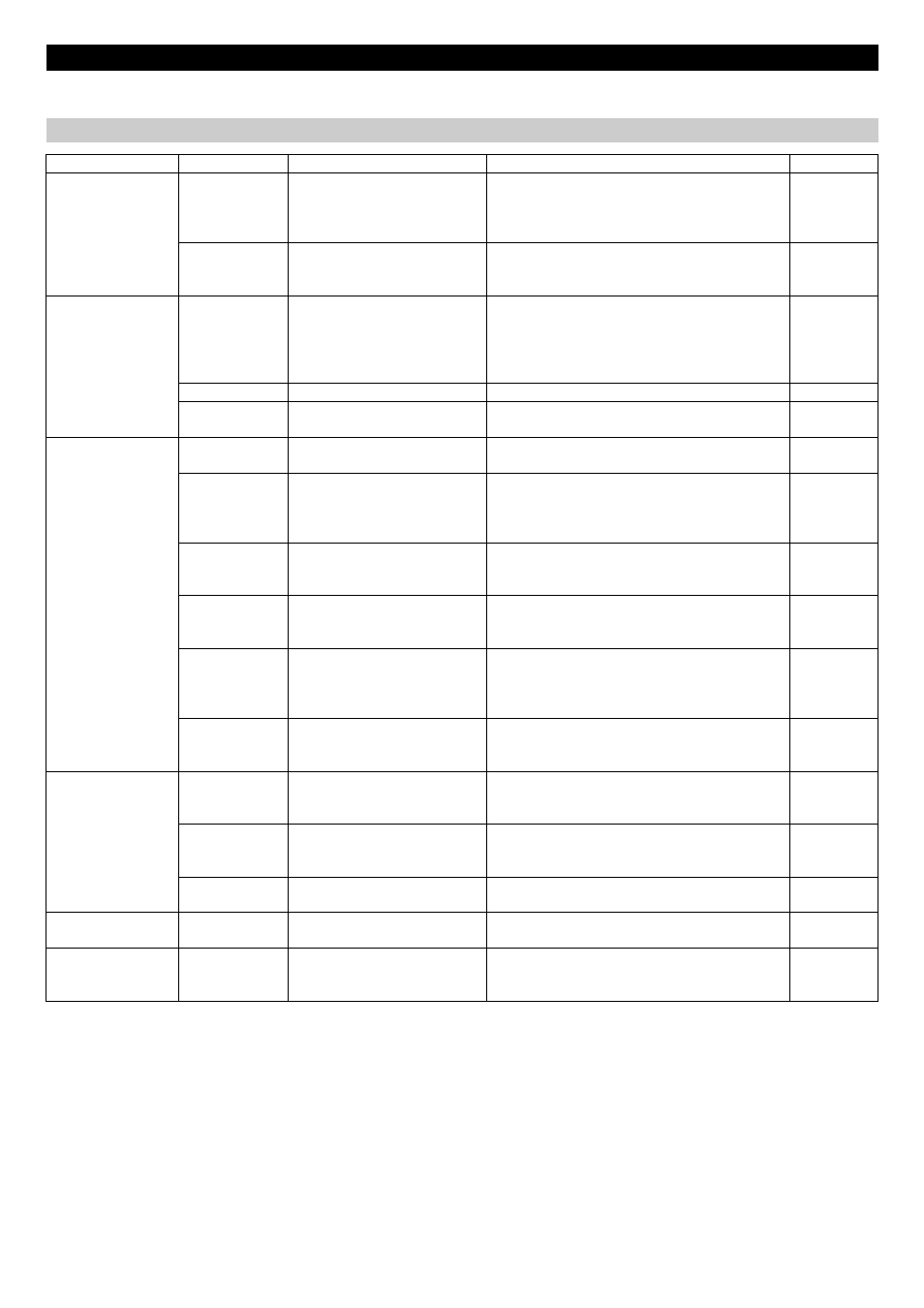

Maintenance schedule

Time

Activity

Assembly affected

Performance

of whom

daily

Check hand-

spray gun

Hand spraygun

Check whether the hand-spray gun closes tightly

without any leaks. Check the protection mecha-

nism against accidental switching. Replace de-

fective hand-spray guns.

Operator

Check high pres-

sure hoses

Outlets, hoses towards working

machine

Check hoses to see if there are damages. Re-

place defect hoses immediately. Danger of acci-

dent!

Operator

weekly or after 40

operating hours

Check the unit

for leaks

Entire plant

Check pumps, overflow valve and pipe system

for leaks. Inform Customer Service if there is oil

below the pump or if there is a leakage of more

than 3 drops of water per minute. Keep the leak-

age borings clear.

Operator/

Customer

service

Check oil level

Oil level indicator on the pump If the oil is milky, it needs to be replaced.

Operator

Check oil level

Oil level indicator on the pump Check oil level of the pump. Refill oil if required

(Order no. 6.288-016)

Operator

monthly or after 200

operating hours

Check pump

High-pressure pump

Check the pump for leaks. If the leakage is more

than 3 drops per minute, call Customer Service.

Operator

Check water

scarcity fuse

Swimmer switch in the swim-

mer tank

Press the swimmer of the low water fuse down

for about 5 seconds and control the error indica-

tor on the control board. Remove deposits if nec-

essary.

Customer

Service

Test swimmer

valve

Swimmer tank

The water level must be 40 mm above the over-

flow. No water must exit while the swimmer valve

is closed. Adjustment - see service manual.

Customer

Service

Check over-

pump time.

Controls

Close consumer loads (e.g. hand spray guns).

The pump must switch off after the afterrun peri-

od.

Operator

Test automatic

start

Pressure sensor

The pump stands still as there is no water trans-

fer. Open the hand spray gun. If the pressure in

the high-pressure cycle falls below the switch-

point, the pump must switch on.

Operator

Tighten hose

clips

All hose clips

Tighten the hose clips using a torque wrench.

Tightening torque up to a diameter of 28 mm =

2Nm, from 29 mm = 6 Nm.

Operator

half-yearly or after

1000 operating

hours

Oil change

High-pressure pump

Drain off oil. Fill in 1 l of fresh oil (order no. 6.288-

016.0). Check the oil level at the oil level indica-

tor.

Operator

Check the appli-

ance for calcium

deposits

entire water system

Improper functioning of valves or pumps can be

an indication of calcium deposits. If necessary

decalcify.

Operator

trained in de-

calcification

Tighten clamps Control board

Tighten all clamps for components in the main

circuit.

Electrician

annual

Safety check

Entire plant

Safety check according to the guidelines for fluid

spraying equipment.

Technical

expert

Depending on ambi-

ent conditions

Check the filter

mats of the ven-

tilator

Control board

Check the filter mats of the ventilator for contam-

ination and clean if necessary. Replace with new

filter mats after cleaning them 10 times.

Customer

Service